Substrate for cell micropatterning growth as well as preparation method and application thereof

A cell pattern and substrate technology, which is applied in the field of patterned cell growth substrate and its preparation, can solve the problems of high price and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1 Printing polydopamine pattern on the surface of PLL-g-PEG modified glass sheet

[0080] 1. Oxidize the glass sheet.

[0081] Cut glass slides (25.4*76.2mm, sailing slides, product number 7101) into 5×5mm sizes, place them in acetone and water for ultrasonic cleaning for 10 minutes, mix concentrated sulfuric acid and hydrogen peroxide at a ratio of 3:1, and mix Soak the cleaned slides in the solution for 30 minutes and blow dry. The glass slides were oxidized in an air plasma oxidizer for 3 min.

[0082] 2. Inert modification of glass slides.

[0083] Soak the oxidized glass piece in 0.1 g / L PLL-g-PEG solution in hydroxyethylpiperazine ethylsulfuric acid (HEPES) solution (pH 7.4, 10 mM) for 2 hours, and use the PLL-g- PEG is PLL(20)-g[3.5]-PEG(5), that is, PLL is 20k, PEG is 5k, and the ratio of lysine to PEG chain in PLL is 3.5.

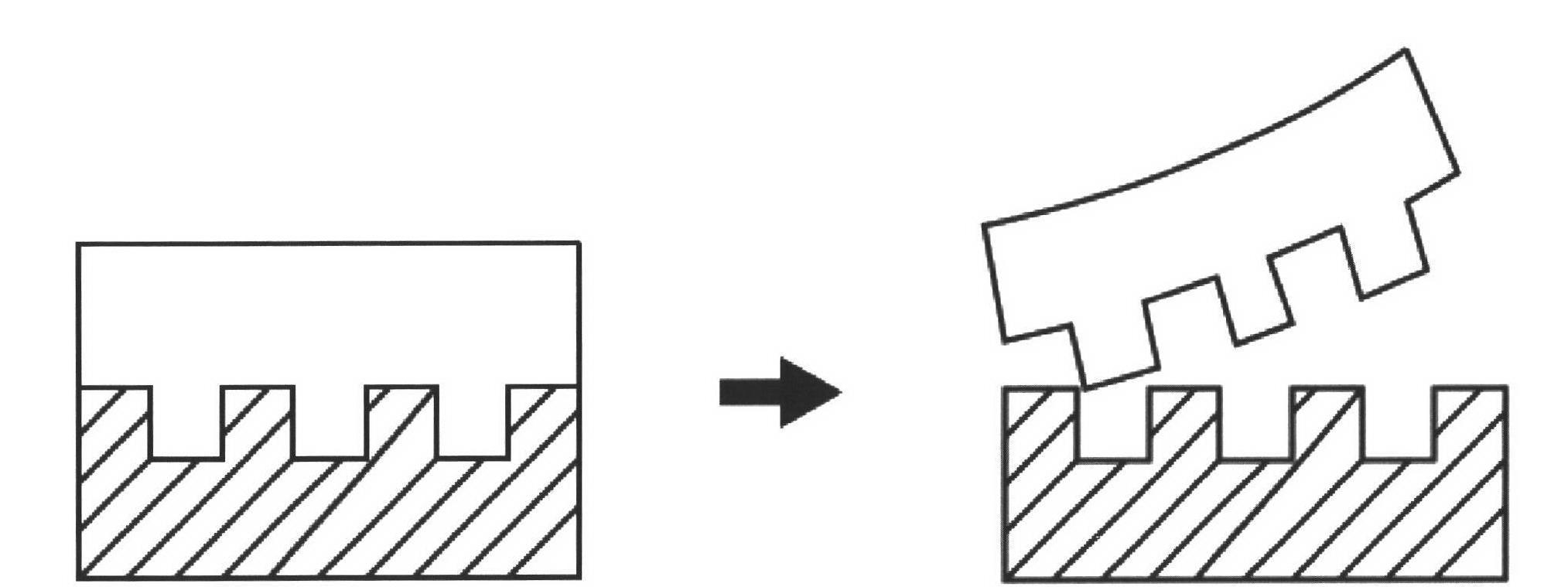

[0084] 3. Prepare a polydimethylsiloxane stamp.

[0085]First, use L-Edit software (The layout Editor Win 32 8.30, Tanner ED...

Embodiment 2

[0091] Example 2 Patterned Growth of Cells on PLL-g-PEG Modified Polystyrene Substrate

[0092] 1. Oxidation treatment of polystyrene flakes.

[0093] Cut a polystyrene (disposable plastic culture dish, Aisijin Medical Plastics Co., Ltd.) petri dish into 5×5 mm pieces, and put the pieces into an air plasma oxidizer to oxidize for 3 minutes.

[0094] 2. Inert modification of polystyrene flakes, wherein 10g / L of PLL-g-PEG solution of hydroxyethylpiperazineethanesulfonic acid (HEPES) solution (pH 7.4, 10mM) was used, and the PLL-g- PEG is PLL(375)-g[5]-PEG(5), that is, PLL is 375k, PEG is 5k, and the ratio of lysine to PEG chain in PLL is 5.

[0095] 3. Prepare a polydimethylsiloxane stamp.

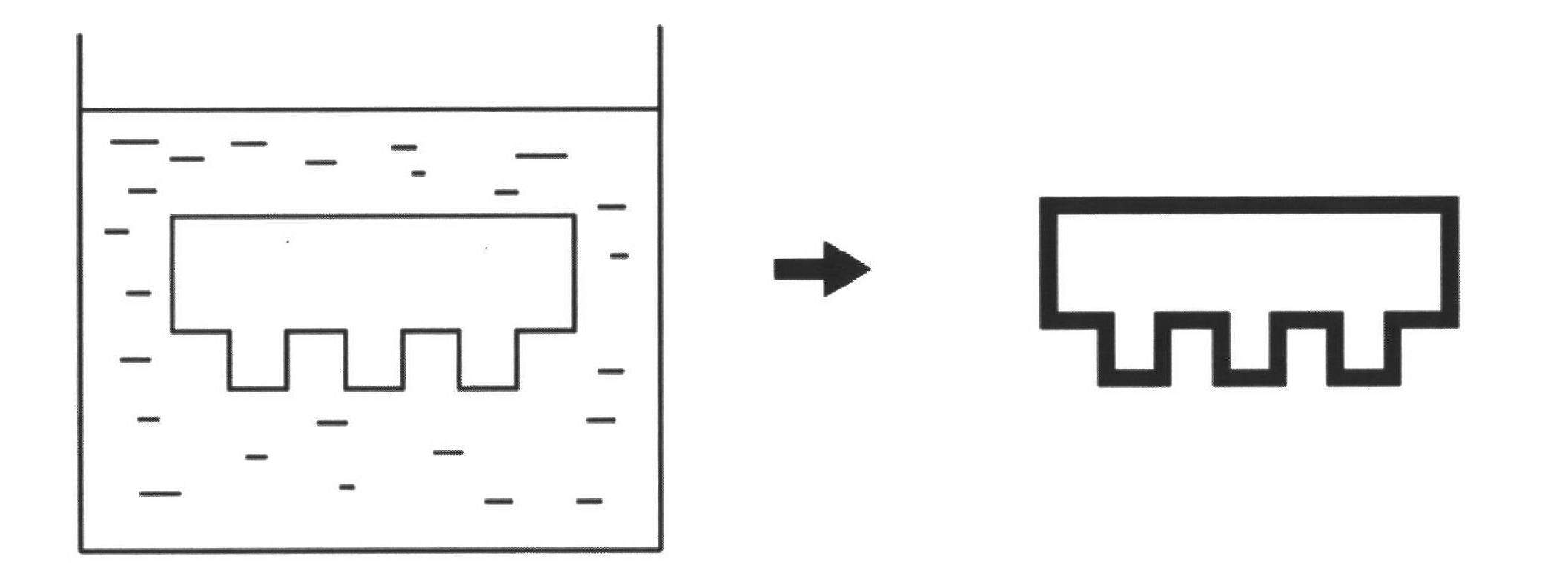

[0096] 4. Polydopamine is formed on the surface of the stamp.

[0097] 5. Print polydopamine on the surface of polystyrene sheet.

[0098] Wherein the steps of 2-5 are consistent with the corresponding steps in embodiment 1.

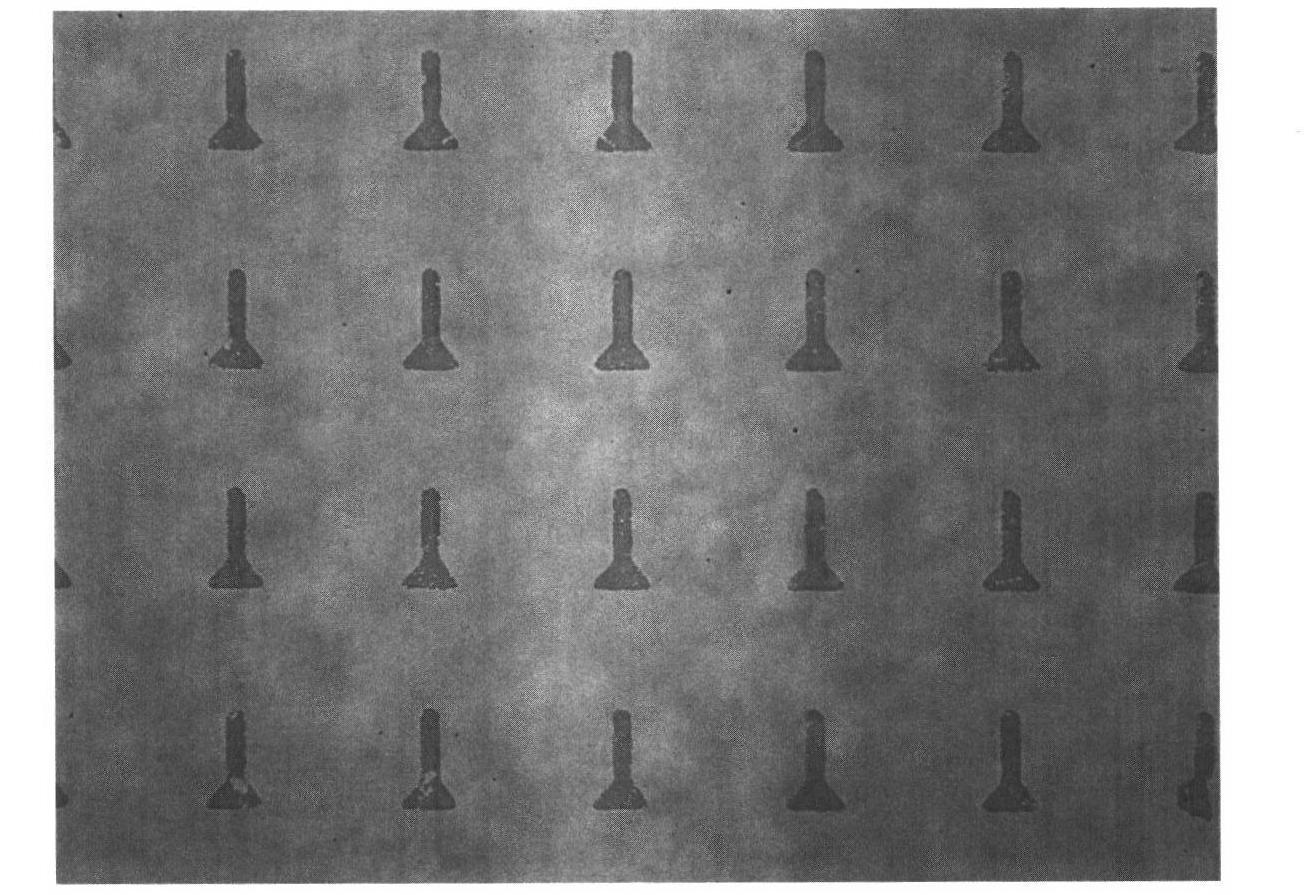

[0099] 6. Inoculate cells on polystyrene surface printed w...

Embodiment 3

[0101] Example 3 Patterned generation of cells on polyethylene glycol dimethacrylate photopolymer long

[0102] 1. Preparation of Polyethylene Glycol Dimethacrylate Photopolymer

[0103] Add 1% (mass ratio) of benzoin dimethyl ether photoinitiator (purchased by sigma company, CAS number is 24650) in polyethylene glycol dimethacrylate liquid (sigma company purchases, CAS number is 25852-47-5) -42-8), oscillate to dissolve, add dropwise in a polystyrene petri dish, and irradiate with 250-400nm ultraviolet light (>60mW) for more than 2 minutes to obtain cured polyethylene glycol dimethacrylate photopolymerization thing. Add water to a Petri dish and let soak overnight. Polyethylene glycol dimethacrylate photopolymer will release itself from the polystyrene surface to form a film. Dry the film in an oven (40°C, 30 minutes).

[0104] 2. Preparation of polydimethylsiloxane stamp.

[0105] 3. Polydopamine is formed on the surface of the stamp.

[0106] 4. Printing polydopam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com