Halloysite with modified surface and preparation method for halloysite

A technology for surface modification and modification, applied in the field of halloysite modified by hyperbranched polysiloxane, which can solve the problem of low phosphorus content in hyperbranched polysiloxane, achieve excellent reactivity, adhesion, and operating process The effect of simplicity and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

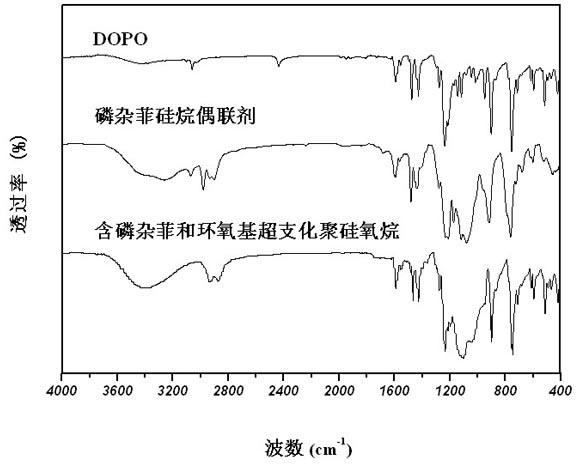

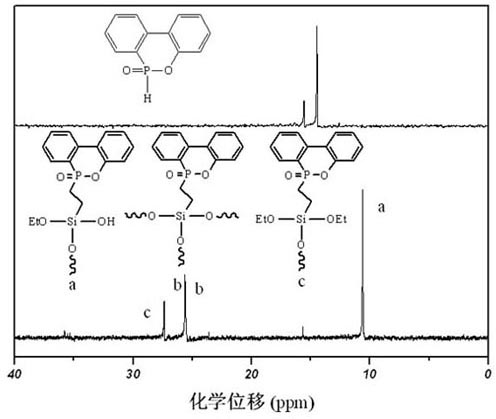

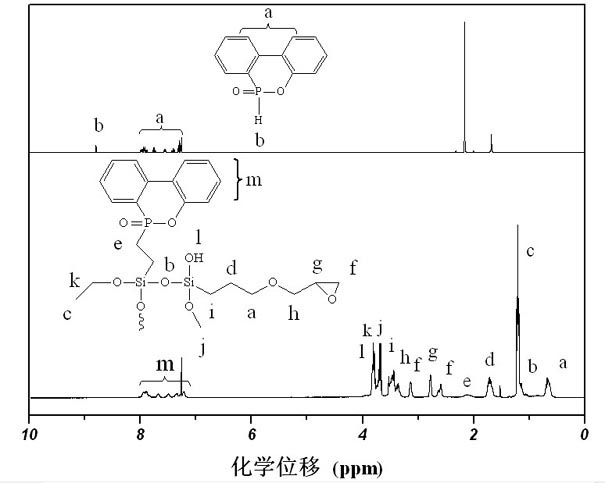

[0036] (1) Under nitrogen protection, 1.9g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO), 1.9g of vinyltriethoxysilane, 0.08g of Add nitrogen diisoheptanonitrile and 10ml dimethylformamide into the flask, and react at 120°C for 2 hours. After the reaction, the solvent was distilled off under reduced pressure to obtain the phosphaphenanthrenesilane coupling agent.

[0037] (2) Under the protection of nitrogen, add 3g of phosphaphenanthrenesilane coupling agent, 3g of glycidyl etheroxypropyl trimethoxysilane, 0.1g of 36wt% hydrochloric acid, 20ml of deionized water and 7ml of methanol into the flask, at 55℃ After the reaction was completed, the solvent was distilled off under reduced pressure to obtain a hyperbranched polysiloxane containing phosphaphenanthrene and epoxy groups, with a molecular weight of 3020 g / mol and a phosphorus content of 14.7 wt%.

[0038] (3) Add 20g of 5mol / L hydrochloric acid solution and 10g of halloysite into the flask, react at 6...

Embodiment 2

[0047] (1) Under the protection of argon, 2.4g 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 1.9g vinyltriethoxysilane, 0.08g azobisiso Butyronitrile and 10ml of chloroform were added into the flask, and reacted at 60°C for 20 hours. After the reaction, the solvent was distilled off under reduced pressure to obtain a phosphaphenanthrenesilane coupling agent.

[0048] (2) Under the protection of argon, add 3g of phosphaphenanthrenesilane coupling agent, 9g of glycidyl etheroxypropyl trimethoxysilane, 0.1g of 36wt% hydrochloric acid, 20ml of deionized water and 28ml of methanol into the flask, and Reacted at 40°C for 8 hours. After the reaction, the solvent was distilled off under reduced pressure to obtain a hyperbranched polysiloxane containing phosphaphenanthrene and epoxy groups with a molecular weight of 2820 g / mol and a phosphorus content of 14.5 wt%.

[0049] (3) Add 50g of 1mol / L hydrochloric acid solution and 10g of halloysite into the flask, react at 80°C for 3 h...

Embodiment 3

[0052] (1) Under nitrogen protection, 2.4g 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 1.9g vinyltriethoxysilane, 0.02g azobisiso Butyronitrile, 0.02g of azobisisoheptanonitrile and 10ml of dichloromethane were added to the flask, and reacted at 60°C for 10 hours. After the reaction, the solvent was distilled off under reduced pressure to obtain a phosphaphenanthrenesilane coupling agent.

[0053] (2) Under nitrogen protection, add 3g of phosphaphenanthrenesilane coupling agent, 9g of glycidyl etheroxypropyl trimethoxysilane, 0.1g of 36wt% hydrochloric acid, 20ml of deionized water, 14ml of ethanol and 14ml of propanol The flask was reacted at 60°C for 5 hours. After the reaction was over, the solvent was distilled off under reduced pressure to obtain a hyperbranched polysiloxane containing phosphaphenanthrene and epoxy groups. The molecular weight was 2880 g / mol, and the phosphorus content was 14.5wt. %

[0054](3) Add 50g of 3mol / L hydrochloric acid solution and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com