Water-resistant polyvinyl alcohol (PVA)-based composite film and preparation method thereof

A polyvinyl alcohol-based, polyvinyl alcohol technology, applied in the field of polymer composite materials, can solve the problems of poor water resistance and poor water resistance, and achieve the effects of excellent mechanical properties, low cost, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

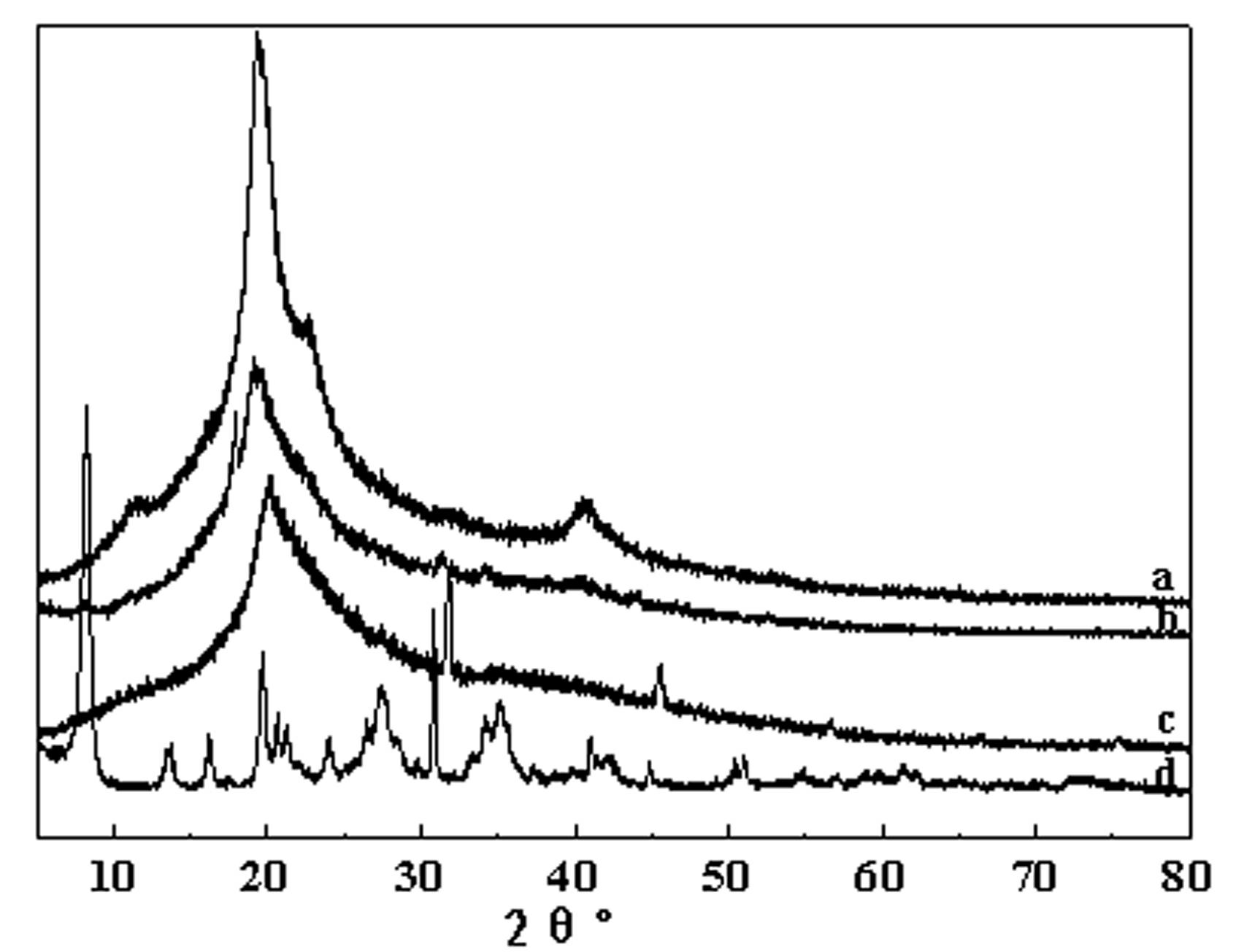

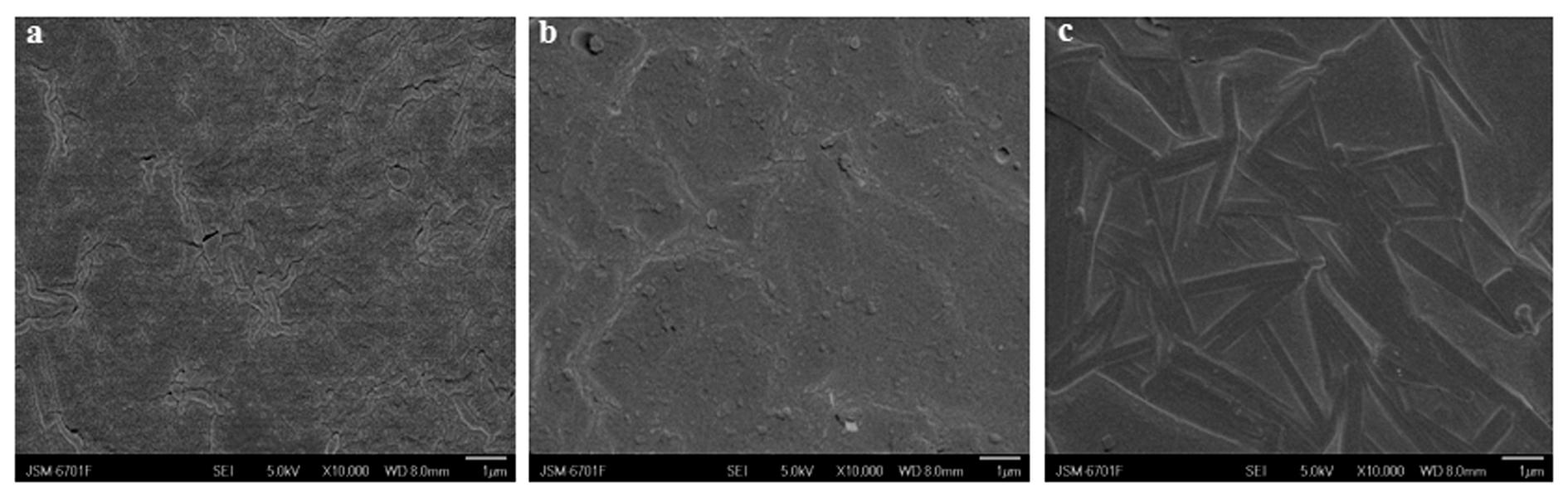

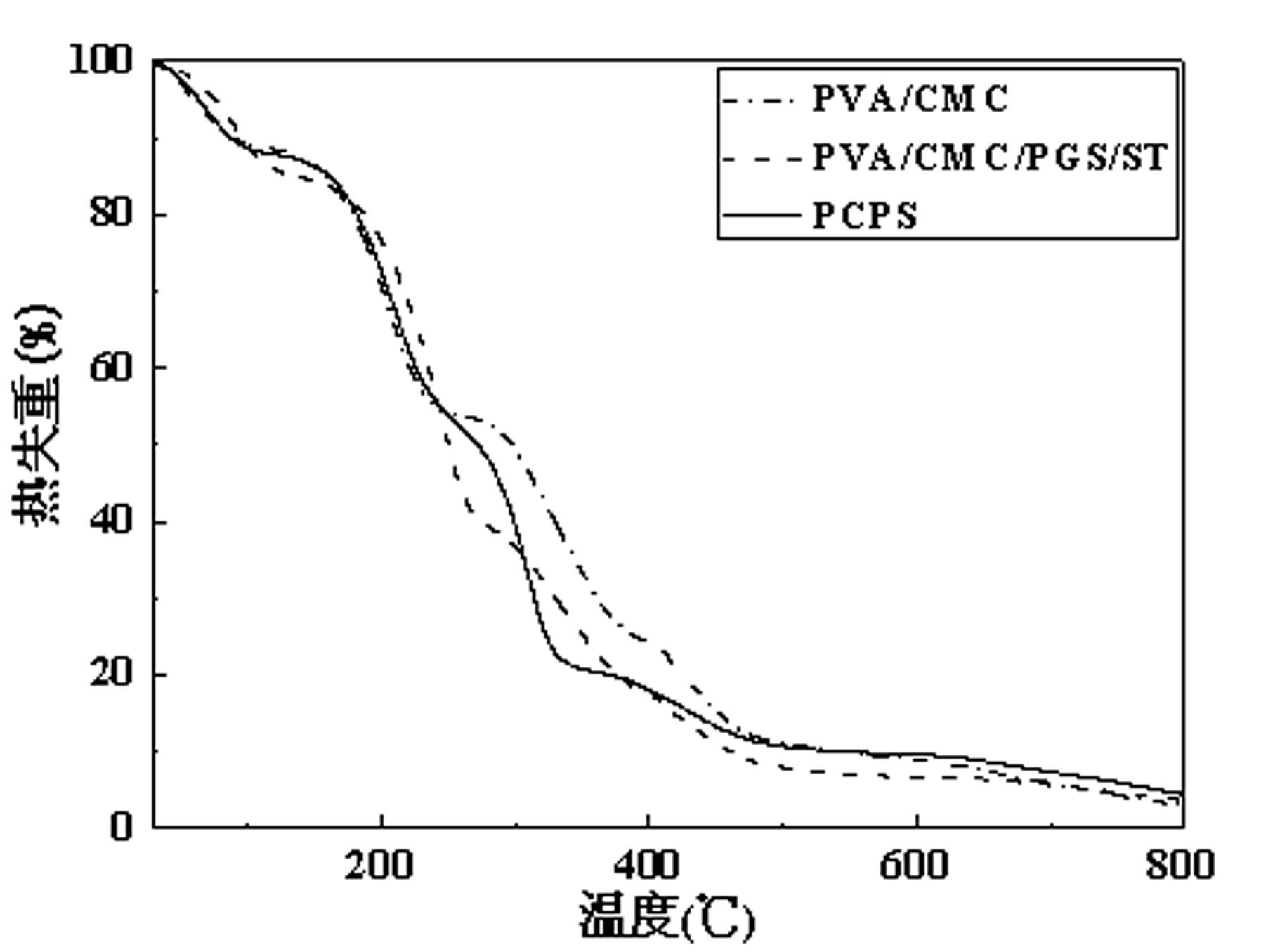

Image

Examples

Embodiment 1

[0040] Stir a certain mass of PVA particles with distilled water at 95°C for 3 hours to fully dissolve it, and configure it into a 2 wt% PVA solution; accurately weigh 20% of the mass of PVA sodium carboxymethyl cellulose, and use distilled water to prepare a uniform solution of 1 wt%. CMC solution; Weigh plant straw powder with 1% PVA mass and PGS with 0.6% PVA mass and ultrasonically disperse in water to form a suspension (ST-PGS) with a total mass concentration of 30%; Mix the PVA solution and CMC solution thoroughly Finally, add the ST-PGS suspension and stir to form a mixed film liquid (the total mass concentration of polyvinyl alcohol, sodium carboxymethyl cellulose, ST and PGS in the mixed liquid film is 2.5%). After mixing evenly, add 10 wt % glycerin as a plasticizer, stirred at 80°C for 15 min, cooled to 30°C, added oxalic acid with 2.5% of PVA mass as a crosslinking agent, adjusted the pH of the mixture to 3, and crosslinked and blended for 10 minutes, Invert the mo...

Embodiment 2

[0043] Stir a certain mass of PVA particles with distilled water at 95°C for 3 hours to fully dissolve it, and prepare a 5 wt% PVA solution; accurately weigh 50% of the mass of PVA sodium carboxymethyl cellulose, and use distilled water to prepare a 2.5 wt% solution Uniform CMC solution; Weigh plant straw powder with 5% PVA mass and PGS with 6% PVA mass and ultrasonically disperse in water to form a suspension with a mass concentration of 50% (ST-PGS); fully mix the PVA solution and the CMC solution Finally, add the ST-PGS suspension and stir to form a mixed film liquid (the total mass concentration of polyvinyl alcohol, sodium carboxymethyl cellulose, ST, and PGS in the mixed liquid film is 5%). After mixing evenly, add 50 wt % methanol as a plasticizer, stirred at 90°C for 30 min, cooled to 60°C, added 10% acetic acid of PVA mass as a crosslinking agent, adjusted the pH of the mixture to 7, and crosslinked and blended for 30 minutes. Invert the mold. Placed in an oven, drie...

Embodiment 3

[0046] Stir a certain mass of PVA particles with distilled water at 95°C for 3 hours to fully dissolve, and prepare a 3 wt% PVA solution; accurately weigh 30% of the mass of PVA sodium carboxymethyl cellulose, and use distilled water to prepare a 2 wt% solution Uniform CMC solution; Weigh plant straw powder with 2% PVA mass and PGS with 1% PVA mass and ultrasonically disperse in water to form a suspension with a mass concentration of 40% (ST-PGS); fully mix the PVA solution and the CMC solution Finally, add the ST-PGS suspension and stir to form a mixed film liquid (the total mass concentration of polyvinyl alcohol, sodium carboxymethyl cellulose, ST and PGS in the mixed liquid film is 3%). After mixing evenly, add 20 wt % ethanol as a plasticizer, stirred at 80°C for 20 min, cooled to 40°C, added citric acid with 4.5% PVA mass as a cross-linking agent, adjusted the pH of the mixture to 4, and cross-linked and blended for 20 min , Invert the mold. Placed in an oven, dried at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com