Detection method for interface bonding strength of particle reinforced metal matrix composite material

A technology of interface bonding strength and composite materials, applied in the direction of analysis materials, measuring devices, instruments, etc., can solve the problems of complex stress state, decrease of interface bonding strength, small size, etc., and achieve simple operation, simple and convenient operation, and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

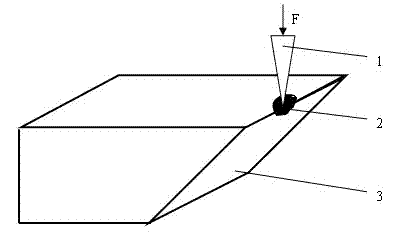

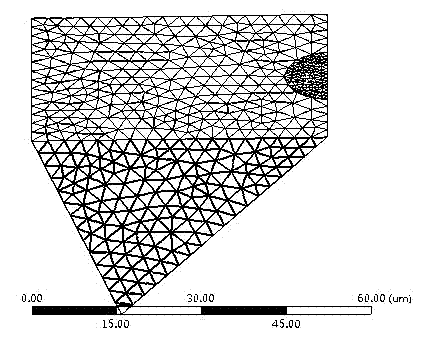

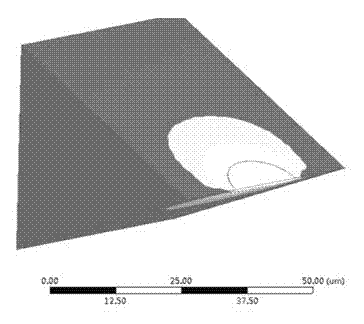

[0024] To measure the bonding strength between SiC particles and aluminum matrix in the SiC particle reinforced A356 matrix composite material prepared by stirring casting method, the SiC particle diameter is about 15 μm, and the particle reinforced metal matrix composite material sample is processed by mechanical processing method to facilitate scanning electron microscope observation For a cuboid sample with a size of 5mm×5mm×10mm, cut off a piece of the cube along one of the 5mm edges, after cutting off, ensure that the two adjacent faces on the edge form an angle of 45o, and carry out the test on these two adjacent faces. Grinding and polishing, on the BN loading head, adhere the conductive adhesive with a diameter of 6 μm, and use the loading head with conductive adhesive under the scanning electron microscope to peel off the particles on the 45° edge of the sample in a vertical loading manner. During the peeling process The sample is fixed on the stage, and after peeling ...

Embodiment 2

[0027] To measure B prepared by high energy ball milling powder metallurgy 4 B in Cp / 6061Al composite 4 C Bonding strength of particles and aluminum matrix, B 4The particle diameter of C is about 0.6 μm. The particle-reinforced metal matrix composite material sample is processed into a cuboid sample with a size of 8mm×8mm×12mm for scanning electron microscope observation by mechanical processing, and the cuboid is cut off along one of the 8mm edges. One piece, cut off to ensure that the two adjacent surfaces on the edge are at an angle of 45o, and the two adjacent surfaces are ground and polished, and a conductive glue with a diameter of 0.3 μm is adhered to the BN loading head. Use a loading head with conductive adhesive to peel off the particles on the 45° edge of the sample in a vertical loading manner. During the peeling process, the sample is fixed on the stage. After peeling, use conductive adhesive to adhere to the particles and observe the shape of the particles , co...

Embodiment 3

[0029] To measure exothermic reactions (XD TM ) method prepared TiB 2 TiB in Particle Reinforced Al-4.5%Cu Alloy Matrix Composites 2 Bonding strength of particles to aluminum matrix, TiB 2 The diameter of the particle is about 2 μm. The particle reinforced metal matrix composite material sample is processed into a cuboid sample with a size of 10mm×10mm×15mm for scanning electron microscope observation by mechanical processing method, and a piece of the cuboid is cut along one of the 10mm edges. After cutting off, ensure that the two adjacent surfaces on the edge form an angle of 45°, and grind and polish the two adjacent surfaces. On the BN loading head, adhere a conductive adhesive with a diameter of about 1 μm. The loading head of the conductive adhesive strips the particles on the 45° edge of the sample in a vertical loading manner. During the stripping process, the sample is fixed on the stage. The shape of the notch left on the aluminum matrix composite material sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com