Preparation method for preparing alkali metal or alkali earth metal cyanide with high purity and high yield

An alkaline earth metal and cyanide technology, which is applied in simple alkali metal cyanide, metal cyanide, chemical industry and other directions, can solve the problem of high power consumption, and achieve the effects of high product purity, high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

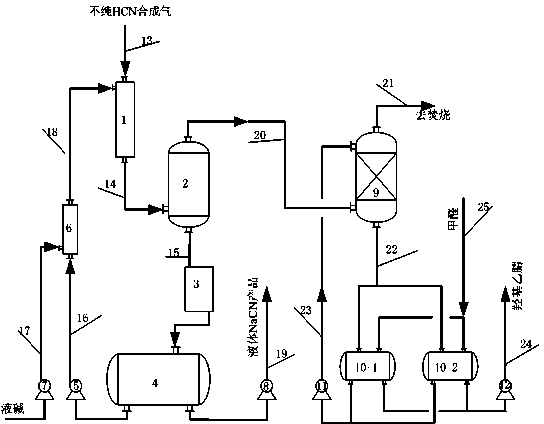

Image

Examples

Embodiment 1

[0043] In a set of industrial reaction device, natural gas, ammonia and air are reacted to synthesize HCN in the reactor by Angle’s method. The initial temperature of HCN synthesis gas is controlled at 150-200°C, and its main components are as follows:

[0044] components

N2

H2O

HCN

CO

NH3

CO2

H2

CH4

Mass fraction / wt%

64.42

18.51

8.52

4.45

1.73

1.37

0.84

0.16

[0045] A kind of adopting above-mentioned HCN synthesis gas to prepare sodium cyanide, hydroxyacetonitrile: add 5m in advance in the sodium cyanide circulation tank 4 The liquid sodium cyanide product, after testing liquid sodium cyanide content is 30.53%wt; Add 2m3 industrial formaldehyde in the acetonitrile circulation tank in advance, and the content of formaldehyde is 37%wt after testing.

[0046] Start the sodium cyanide circulation pump for circulation, and start the hydroxyacetonitrile pu...

Embodiment 2~7

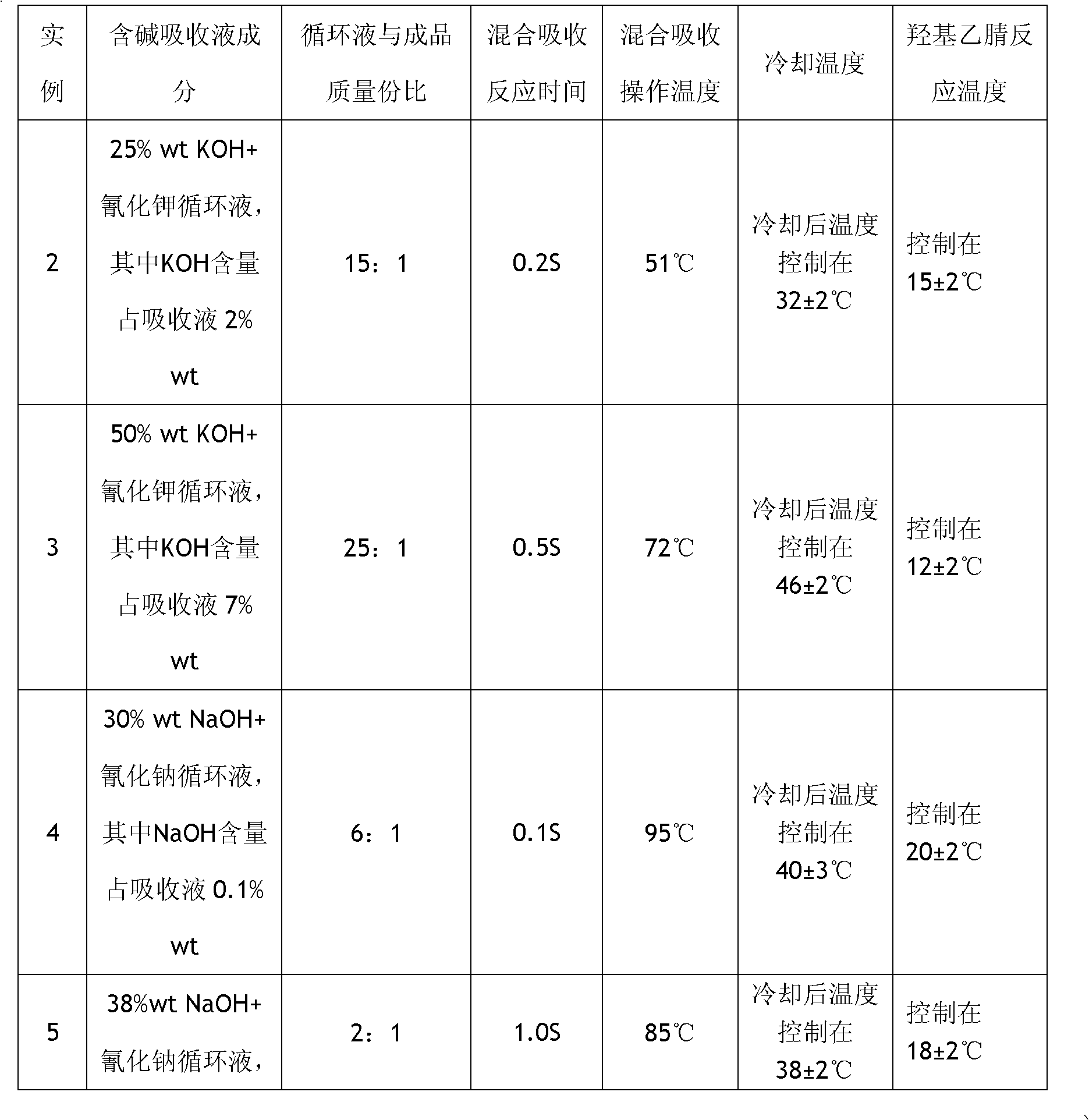

[0050] Embodiment 2~7: be continuous production process, make sodium cyanide or potassium cyanide by following steps and process, all the other are with embodiment 1.

[0051]

[0052]

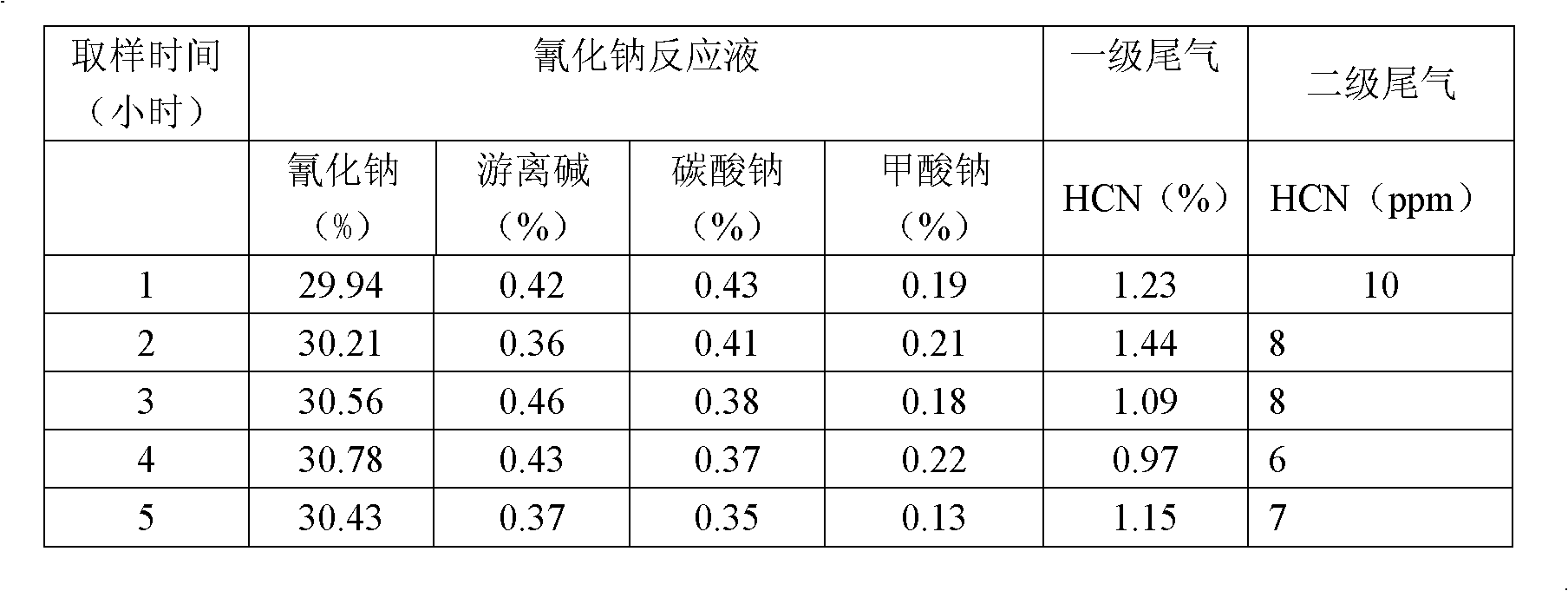

[0053] In the sodium cyanide or potassium cyanide liquid product that makes by example 2~7, sodium carbonate or salt of wormwood content have been controlled at extremely low level, at 0.30~0.45%wt, sodium hydroxide or potassium hydroxide (free alkali ) content is controlled at 0.2-0.8%wt, sodium formate or potassium formate is controlled at 0.1-0.15%wt, the product sodium cyanide or potassium cyanide is at 20-40%wt, and the product has good quality and high purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com