Preparation method for hexagonal sheet magnesium hydroxide

A technology of magnesium hydroxide and hexagonal flakes, applied in the direction of magnesium hydroxide, etc., can solve the problems of environmental pollution, inability to control the size and thickness of magnesium hydroxide particles, etc., and achieve low production costs, easy control of shape, and short time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

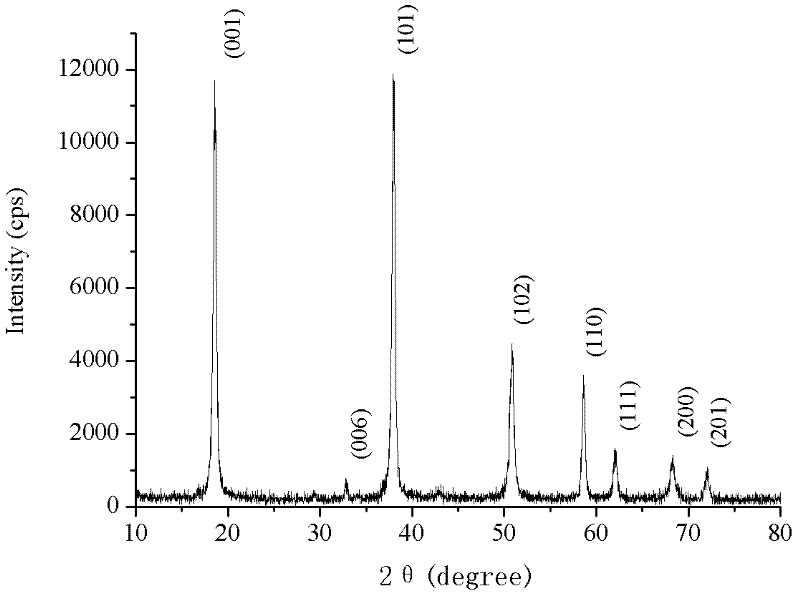

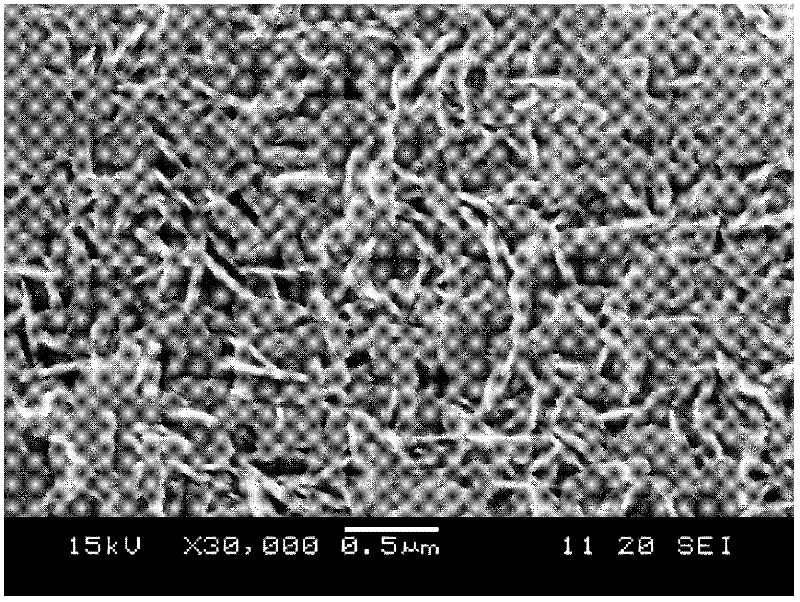

[0024] Weigh 2 g of magnesium oxide obtained by calcination of magnesite at 600 ° C for 8 hours and pass through a 200 mesh sieve, add 0.6 g of magnesium sulfate and 50 ml of water into the aqueous solution, and mix well, control the temperature of the water bath at 40 ° C, and add 0.4 g magnesium hydroxide crystal seed, continue to react 23h under the condition of constant stirring, stop stirring; The Mg(OH) 2 Slurry is filtered, washed and dried to obtain hexagonal flaky magnesium hydroxide product. Generated Mg(OH) 2 Crystal XRD such as figure 1 as shown, figure 2 It is a scanning electron microscope photo of the product obtained in this example. It can be seen from the figure that the product is a hexagonal sheet with a diameter of about 500 nm, a uniform particle size distribution, and a thickness of about 20 nm.

Embodiment 2

[0026] Magnesite was calcined at 800°C for 6 hours, and passed through a 200-mesh sieve to obtain active magnesium oxide. Weighed 2g of the above-mentioned magnesium oxide and added it to an aqueous solution composed of 2g of magnesium sulfate and 100ml of water to obtain a uniformly mixed suspension of magnesium oxide. The reaction temperature was controlled to 60°C, react for 30min, add 0.2g magnesium hydroxide seed, continue to react for 4h under constant stirring, stop stirring; control crystal growth temperature 40°C, keep at this temperature for 24h, grow Mg(OH) 2 crystals, and finally, the resulting Mg(OH) 2 The slurry is filtered and dried to obtain the magnesium hydroxide product. The product is a regular hexagonal sheet with a particle size of about 200-300nm and a thickness of about 50nm.

Embodiment 3

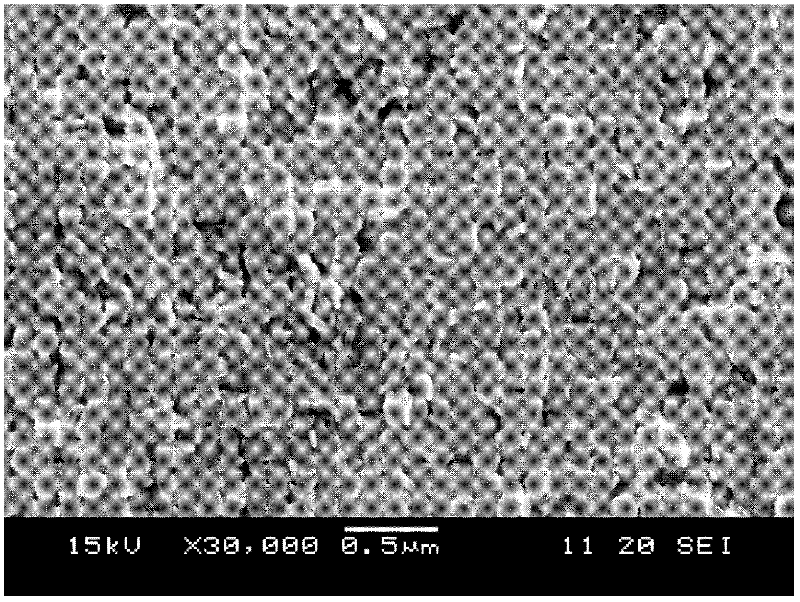

[0028] Weigh 4g of magnesium oxide obtained by calcining magnesite at 950°C for 6h and passing through a 200-mesh sieve, add 8g of magnesium nitrate and 200ml of water into the aqueous solution, mix well, adjust the temperature of the water bath to 80°C, and add 0.1g of hydroxide after 10min of reaction Magnesium seed, continue to react for 40min under the condition of constant stirring, stop stirring; control crystal growth temperature 70 ℃, keep warm at this temperature for 48h, and the prepared Mg(OH) 2 The slurry is filtered, washed and dried to obtain powdery magnesium hydroxide. image 3 For the scanning electron microscope photo of this example, by image 3 It can be seen that the product is in the shape of hexagonal flakes, with a particle size of 100nm-200nm and a thickness of about 40nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com