Method for producing high-purity alpha-aluminum oxide

A technology of alumina and aluminum hydroxide, applied in the direction of alumina/hydroxide, etc., can solve the problems of high product impurity content, high energy consumption, serious environmental pollution, etc., and achieve low production cost, low energy consumption, and technological process short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

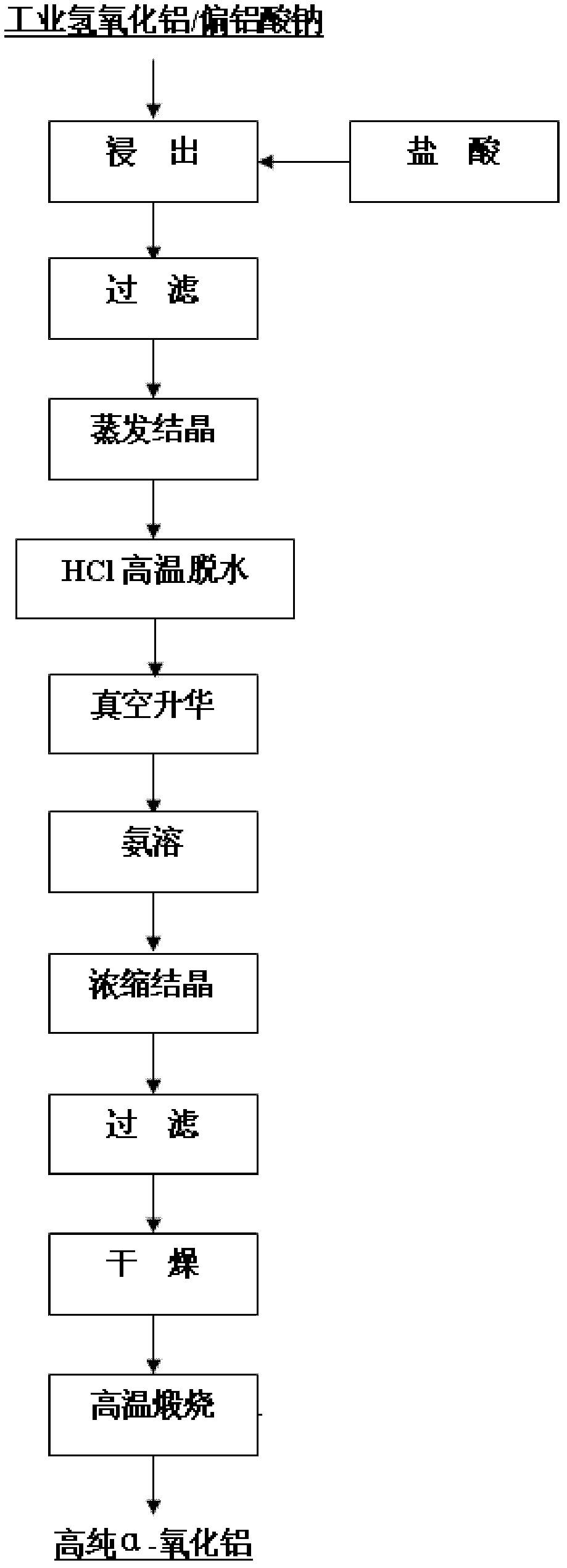

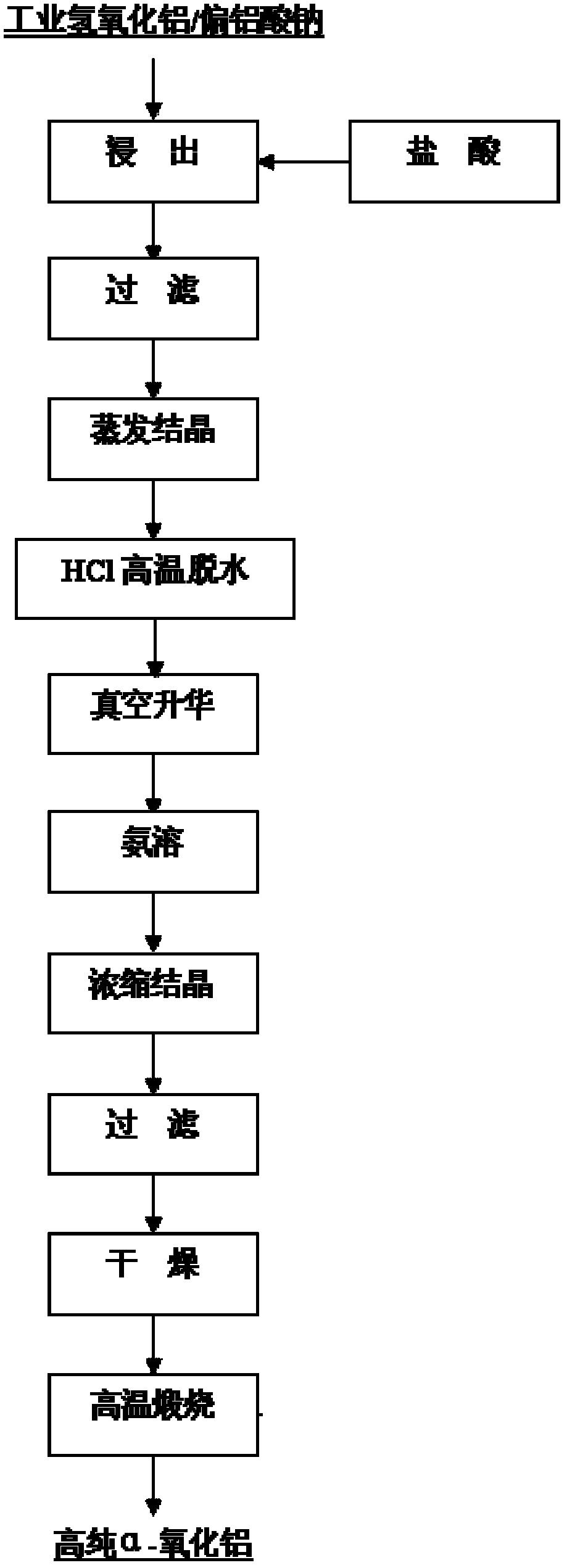

Method used

Image

Examples

Embodiment 1

[0016] Use industrial aluminum hydroxide with a purity of 98.5~99% as raw material. React the raw material with 15-25% hydrochloric acid solution in the reaction tank for 3 hours according to the liquid-solid ratio of 5:1 to obtain aluminum trichloride solution. After the aluminum trichloride solution is filtered, the filtrate is evaporated and crystallized at 80~90°C for 3~4 hours to obtain aluminum trichloride hexahydrate crystals. 3 Under the protection of hydrogen chloride gas per hour, dehydrate at 120~150℃ to obtain anhydrous aluminum trichloride powder, which is placed in a vacuum furnace to maintain a vacuum of 1~10Pa and control the sublimation temperature to 165 ℃ until the vacuum degree drops significantly to obtain aluminum trichloride with a purity exceeding 99.999%. The high-purity aluminum trichloride obtained by sublimation is dissolved in ammonia water for reaction, and the reaction temperature is kept at 20~30°C. After filtering, it is dried until the moistu...

Embodiment 2

[0019] Use industrial sodium metaaluminate with a purity of 90-95% as raw material. React the raw material with 20-30% hydrochloric acid solution in the reaction tank for 10 hours according to the liquid-solid ratio of 8:1 to obtain aluminum trichloride solution. After the aluminum trichloride solution is filtered, the filtrate is evaporated and crystallized at 90~100°C for 5~6 hours to obtain aluminum trichloride hexahydrate crystals. 3 Under the protection of hydrogen chloride gas per hour, dehydrate at a high temperature at 150~200°C to obtain anhydrous aluminum trichloride powder. The anhydrous aluminum trichloride powder is placed in a vacuum furnace to maintain a vacuum degree of 10~10 2 Pa, control the sublimation temperature at 175°C until the vacuum degree drops significantly to obtain aluminum trichloride with a purity exceeding 99.999%. The high-purity aluminum trichloride obtained by sublimation is dissolved in ammonia water for reaction, and the reaction temperat...

Embodiment 3

[0022] Use industrial aluminum hydroxide with a purity of 85-90% as raw material. React the raw material with 10-20% hydrochloric acid solution in the reaction tank for 2 hours according to the liquid-solid ratio of 8:1 to obtain aluminum trichloride solution. After the aluminum trichloride solution is filtered, the filtrate is evaporated and crystallized at 110~130°C for 6~8 hours to obtain aluminum trichloride hexahydrate crystals. 3 Under the protection of hydrogen chloride gas per hour, dehydrate at a high temperature of 200~250°C to obtain anhydrous aluminum trichloride powder. The anhydrous aluminum trichloride powder is placed in a vacuum furnace, and the vacuum degree is kept at 0.1~1Pa, and the sublimation temperature is controlled at 168 ℃ until the vacuum degree drops significantly to obtain aluminum trichloride with a purity exceeding 99.999%. The high-purity aluminum trichloride obtained by sublimation is dissolved in ammonia water for reaction, and the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com