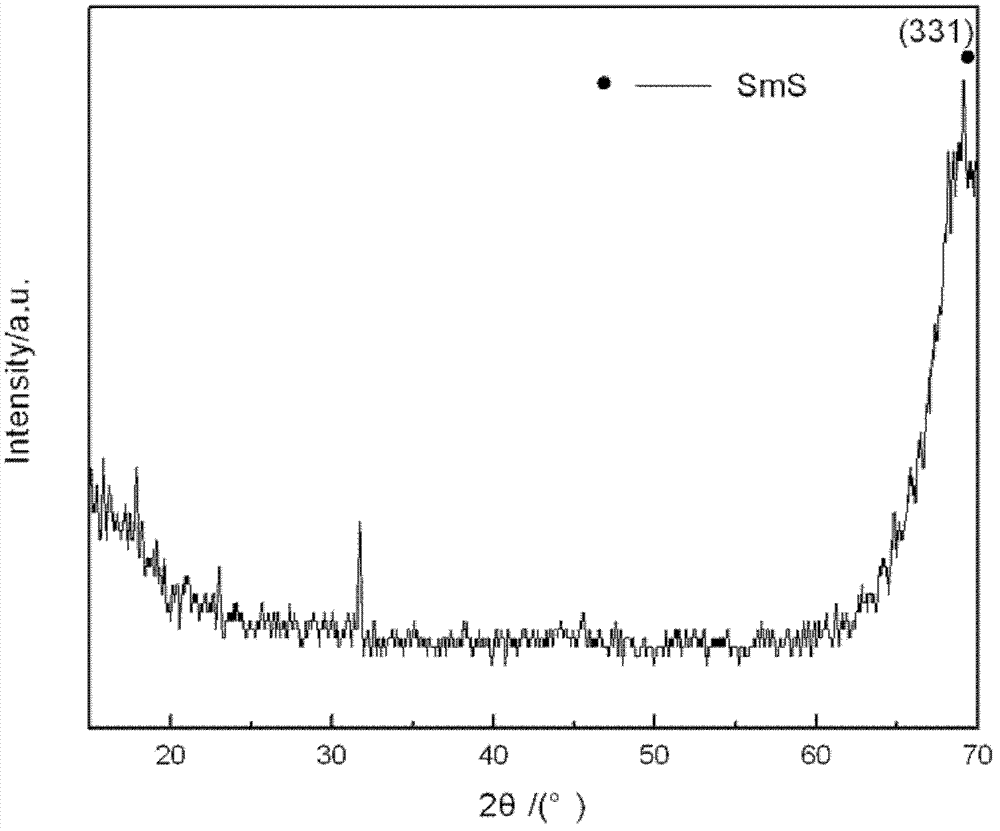

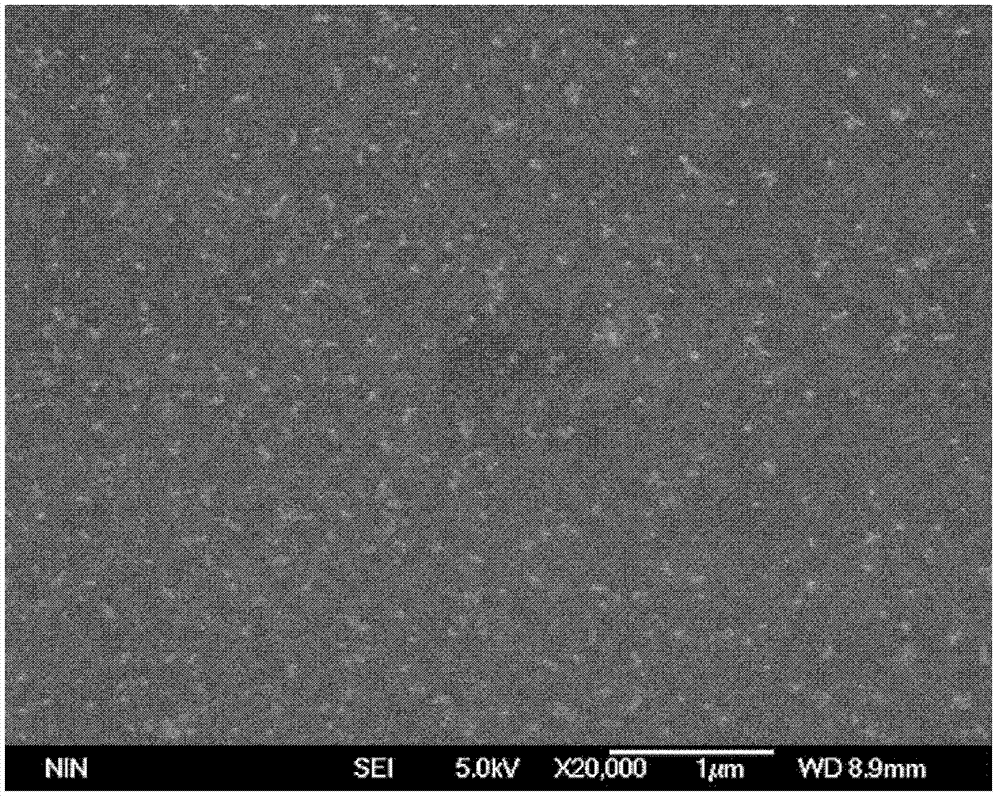

Preparation method of monocrystalline silicon surface aminosilane-samarium sulfide film

A technology of aminosilane and samarium sulfide, which is applied in the field of preparation of samarium sulfide thin films, can solve the problems of inability to prepare high-performance thin films, high cost of samarium sulfide thin films, complicated preparation process, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Take 0.1ml of tetrahydrofuran solution of samarium diiodide with a concentration of 0.1mol / L in a beaker, then add 20mL of tetrahydrofuran into the beaker and stir to obtain solution A;

[0019] 2) Add 0.1 g of EDTA (ethylenediaminetetraacetic acid) to solution A, and magnetically stir at room temperature to obtain solution B;

[0020] 3) Add 0.05g analytically pure thiourea (CH 4 N 2 S) stir to obtain solution C;

[0021] 4) adjust the pH value of solution C to 2.5 with ammonia water to obtain precursor solution D;

[0022] 5) Soak the silicon substrate in aqua regia, use ultrasonic vibration for 60 minutes, cool it naturally at room temperature, and then wash it repeatedly with deionized water. 2 Blow dry, and then irradiate for 30 minutes in an ultraviolet irradiator to obtain a hydroxylated silicon substrate;

[0023] The hydroxylated silicon substrate was placed in an anhydrous methanol solution of APTS (3-aminopropylmethyltriethoxysilane) with a volume conc...

Embodiment 2

[0028] 1) Take 0.5ml of a tetrahydrofuran solution of samarium diiodide with a concentration of 0.1mol / L and place it in a beaker, then add 10mL of tetrahydrofuran to the beaker and stir evenly to obtain solution A;

[0029] 2) Add 0.5 g of EDTA (ethylenediaminetetraacetic acid) to solution A, and stir magnetically at room temperature to obtain solution B;

[0030] 3) Add 0.01g analytically pure thiourea (CH 4 N 2 S) stir to obtain solution C;

[0031] 4) adjust the pH value of solution C to 3 with ammonia water to obtain precursor solution D;

[0032] 5) Soak the silicon substrate in aqua regia, use ultrasonic vibration for 30 minutes, cool it naturally at room temperature, and then wash it repeatedly with deionized water. 2 Blow dry, and then irradiate for 50 minutes in an ultraviolet irradiator to obtain a hydroxylated silicon substrate;

[0033] Put the hydroxylated silicon substrate in an anhydrous methanol solution with a volume concentration of 0.8% APTS (3-aminopro...

Embodiment 3

[0037] 1) Take 3.0ml of tetrahydrofuran solution of samarium diiodide with a concentration of 0.1mol / L in a beaker, then add 40mL of tetrahydrofuran into the beaker and stir to obtain solution A;

[0038] 2) Add 0.8 g of EDTA (ethylenediaminetetraacetic acid) to solution A, and stir magnetically at room temperature to obtain solution B;

[0039] 3) Add 0.8g analytically pure thiourea (CH 4 N 2 S) stir to obtain solution C;

[0040] 4) adjust the pH value of solution C to 3.5 with ammonia water to obtain precursor solution D;

[0041] 5) Soak the silicon substrate in aqua regia, use ultrasonic vibration for 120 minutes, cool it naturally at room temperature, and then wash it repeatedly with deionized water, and wash it with N 2 Blow dry, and then irradiate for 40 minutes in an ultraviolet irradiator to obtain a hydroxylated silicon substrate;

[0042] The hydroxylated silicon substrate was placed in an anhydrous methanol solution of APTS (3-aminopropylmethyltriethoxysilane)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com