Gamma-polyglutamic acid/hydroxyapatite composite material and preparation method thereof

A technology of hydroxyapatite and polyglutamic acid, which is applied in the field of biomedicine, can solve the problems of not preparing γ-polyglutamic acid/hydroxyapatite composite materials, etc., and achieve the improvement of osseointegration ability, mechanical properties, The effect of promoting repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] According to the amount of calcium ions and phosphorus ions in the chemical formula of hydroxyapatite, that is, the molar ratio of Ca: P=5: 3, calcium chloride and sodium dihydrogen phosphate are selected to prepare calcium ion solutions with a concentration of 10 mol / L and a concentration of 6mol / L phosphorus ion solution. The mass fraction is 2.0% gamma-polyglutamic acid aqueous solution, the molar ratio of carboxyl and calcium ion in the gamma-polyglutamic acid solution is the ratio of 6: 1, the gamma-polyglutamic acid aqueous solution is added to the calcium ion solution, the reaction was stirred at room temperature for 5 hours. In the reaction solution of γ-polyglutamic acid and calcium ions, add phosphorus ion solution of the same volume as the calcium ion solution drop by drop, stir while adding, control the reaction pH value to 8.5-10, after the dropwise addition is completed, then Stir for 24 hours, then age for two days, that is, stand at room temperature, so...

Embodiment 2

[0019] According to the amount of calcium ions and phosphorus ions in the chemical formula of hydroxyapatite, i.e. the molar ratio of Ca:P=5:3, choose calcium carbonate and potassium dihydrogen phosphate to prepare calcium ion solutions with a concentration of 40mol / L and a concentration of 24mol respectively. / L of phosphorus ion solution. The mass fraction is 2.0% gamma-polyglutamic acid aqueous solution, the molar ratio of carboxyl and calcium ion in the gamma-polyglutamic acid solution is the ratio of 4:1, the gamma-polyglutamic acid aqueous solution is added to the calcium ion solution, the reaction was stirred at room temperature for 4 hours. In the reaction solution of γ-polyglutamic acid and calcium ions, add phosphorus ion solution of the same volume as the calcium ion solution drop by drop, stir while adding, control the reaction pH value to 8.5-10, after the dropwise addition is completed, then Stir for 24 hours, then age for two days to obtain a γ-polyglutamic aci...

Embodiment 3

[0021] According to the amount of calcium ions and phosphorus ions in the chemical formula of hydroxyapatite, i.e. the molar ratio of Ca:P=5:3, choose calcium hydroxide and dipotassium hydrogen phosphate to configure the calcium ion solution and concentration of 60mol / L respectively 36mol / L phosphorus ion solution. The mass fraction is 6.0% gamma-polyglutamic acid aqueous solution, the molar ratio of carboxyl and calcium ion in the gamma-polyglutamic acid solution is the ratio of 2: 1, the gamma-polyglutamic acid aqueous solution is added to the calcium ion solution, the reaction was stirred at room temperature for 3 hours. In the reaction solution of γ-polyglutamic acid and calcium ions, add phosphorus ion solution of the same volume as the calcium ion solution drop by drop, stir while adding, control the reaction pH value to 8.5-10, after the dropwise addition is completed, then Stir for 24 hours, then age for two days to obtain a γ-polyglutamic acid / hydroxyapatite solution...

PUM

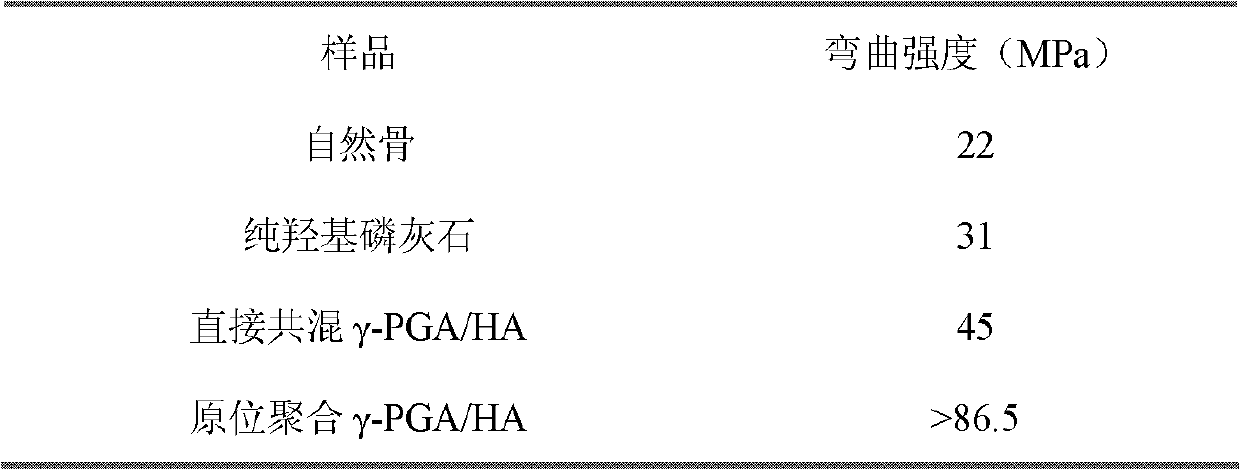

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com