Centimeter wave-millimeter wave compatible absorbing composite material

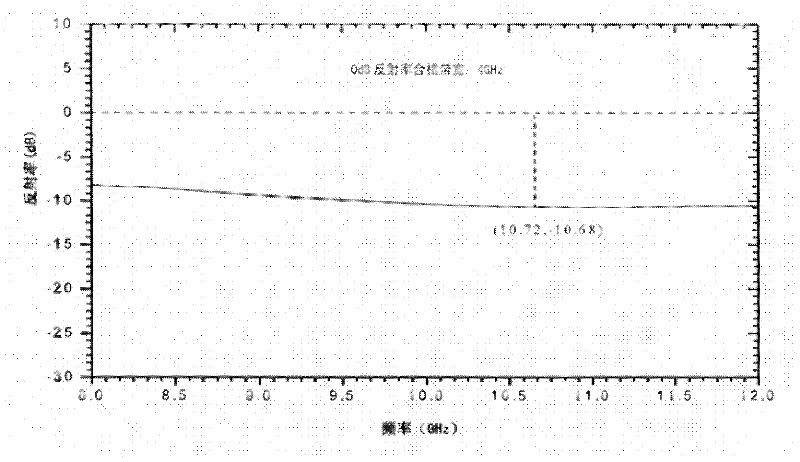

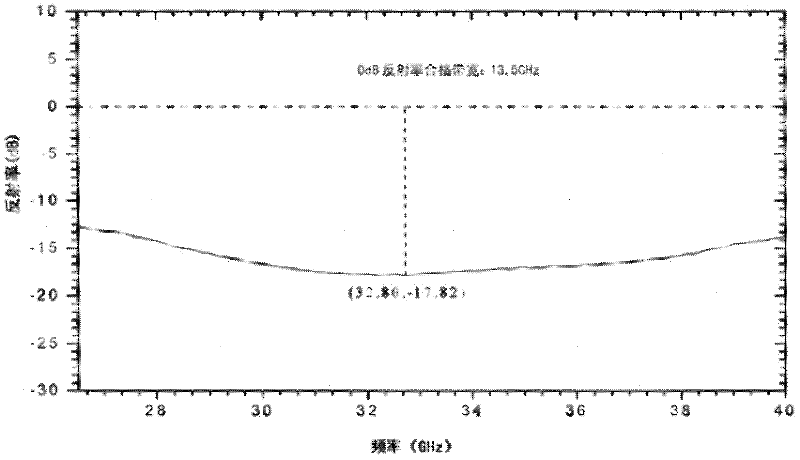

A composite material and millimeter-wave technology, applied in radiation-absorbing coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problem that centimeter-millimeter waves cannot be well compatible with wave-absorbing performance, and achieve good impedance Matching Effects, Reflection Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

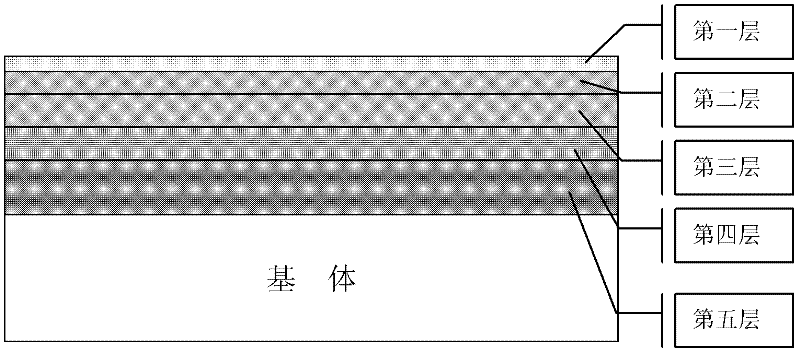

Image

Examples

Embodiment 1

[0029] 1. Take 1g of coupling agent, dilute it with 50g of diluent mixed with xylene and n-butanol with a volume ratio of 7:3, and add a coupling agent with a diameter of 2 to 5 microns and an aspect ratio of 6:1 to 10:1. Mix chopped carbon fiber and carbon black with a particle size of 1 to 3 microns in a mass ratio of 1:8 to 1:5 to form a composite absorbent 45g into it, and stir the mixture with an electric mixer for half an hour; after standing for half an hour, then Add 55g of polyurethane adhesive to the mixture, stir to form a uniform coating; apply the coating on the substrate by air spraying or brushing, the thickness is controlled at 0.5-0.6mm, and then put it in a constant temperature drying room at 30°C for 1 hour, Then raise the temperature of the drying room to 60° C. for 1 hour to cure, or place it at room temperature for 12 hours to cure naturally, so as to prepare the fifth layer of dielectric coating.

[0030] 2. Take 1g of coupling agent, dilute it with 50g ...

Embodiment 2

[0035] Step is the same as embodiment 1, wherein in the first layer BaCo 0.9 Zn 1.1 Fe 16 o 27 60g of W-type hexagonal ferrite, 40g of acrylic resin adhesive; the raw materials of the second layer of dielectric coating include: adding 70g of spherical carbonyl iron powder with a particle size of 3 to 5 microns, and 30g of epoxy resin adhesive; the third layer Raw materials for dielectric coating include: Fe 85 Si 1 Al 6 Cr 8 75g of nanosheet-shaped absorbent, 25g of epoxy resin adhesive; the raw materials of the fourth layer of dielectric coating include adding 20g of polycrystalline iron fiber absorbent with a diameter of 3 to 6 microns and an aspect ratio of 15:1 to 20:1 , 80g of epoxy resin adhesive; the raw materials of the fifth layer of dielectric coating include adding short-cut carbon fibers with a diameter of 2 to 5 microns and an aspect ratio of 6:1 to 10:1 and carbon black with a particle size of 1 to 3 microns. The mass ratio is 1:8 to 1:5 to form a composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com