Nanometer heat isolation paint and preparation method thereof

A nano-insulation and heat-insulating filler technology, applied in the direction of coating, can solve the problems of destroying the stability of the coating, poor adhesion of the coating, failing to achieve the expected purpose, etc., to improve the suspension stability, enhance the effect, increase the Affinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A nano heat-insulating coating of the present invention is formed by mixing pigments, film-forming substances, heat-insulating fillers and additives in a solvent. The mass percentage of each raw material is: pigment: titanium dioxide 32%; film-forming substance: acrylic resin 30%; thermal insulation filler: 6% nano-zirconia, 11% nano-alumina; additives: 1% wetting agent, 1% dispersant, 1% defoamer, 1% silane coupling agent, multifunctional additive 1%; solvent: water 16% for batching.

[0049] The titanium dioxide is obtained by calcining anatase-type titanium dioxide at 900°C for 2 hours, then grinding and controlling its particle size to ≤50 μm;

[0050] The particle size of the nano-zirconia is 10-20 ;

[0051] The one-dimensional diameter of the alumina fiber is 10-20 .

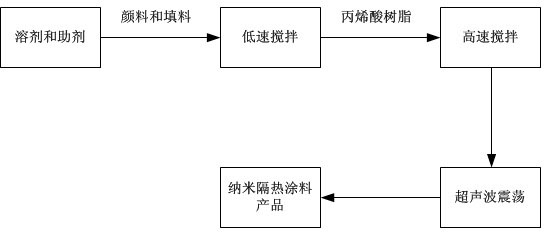

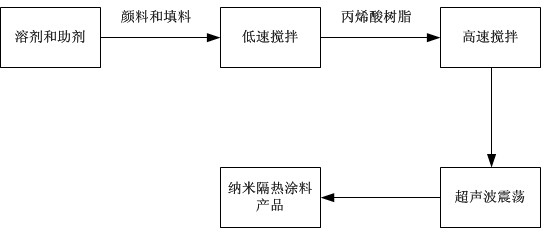

[0052] The preparation method of above-mentioned nano heat insulating coating adopts following steps:

[0053]Weigh the material according to the mass percentage of each component in the for...

Embodiment 2

[0066] The same preparation method as in Example 1, except that the mass percentages of each raw material are different. The mass percentages of each raw material in this example are: pigment: titanium dioxide 36%; film-forming material: acrylic resin 25%; Thermal insulation filler: 6% nano-zirconia, 10% nano-alumina; additives: 2% wetting agent, 2% dispersant, 2% defoamer, 2% silane coupling agent, 2% multifunctional additive; Solvent: water 13%.

Embodiment 3

[0068] The same preparation method as in Example 1, except that the mass percentages of each raw material are different. The mass percentages of each raw material in this example are: pigment: 30% titanium dioxide; film-forming material: 20% acrylic resin; Thermal insulation filler: 7% nano-zirconia, 12% nano-alumina; additives: 0.6% wetting agent, 0.6% dispersant, 0.6% defoamer, 0.6% silane coupling agent, 0.6% multifunctional additive; Solvent: water 28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com