C/SiO2/SiC wave-absorbing composite material and preparation method thereof

A composite material and composite technology, applied in the field of functional composite materials, can solve the problems of complex preparation process, narrow absorption frequency band, poor applicability, etc., and achieve the effect of high dielectric loss, stable performance, improved conversion rate, and thinner thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A tubular reactor such as Figure 6-8As shown, it is a cylindrical body, one end is provided with an air inlet (1), and the other end is provided with an air outlet (2). The inner wall of the tubular reactor is provided with 2 to 4 spirals with a width of 1mm to 100mm (a). The sheet (5), the helical sheet (5) maintains an inclination angle of 35° with the central axis of the reactor; and the inner wall of the tubular reactor is regularly arranged with tapered knife edges (4) with a height of 2 mm to 5 mm. Wherein, the inclination angle between the helical piece (5) and the central axis of the reactor can be designed as different angles according to needs, and 20°-60° are all suitable angles. The helical sheets (5) can be 2 to 4 continuous or discontinuous helical sheets, and the pitch (b) between the helical sheets can be designed according to requirements, and 100 mm to 500 mm is more suitable.

Embodiment 2

[0042] With the tubular reactor described in embodiment 1 as reaction equipment, prepare C / SiO 2 / SiC absorbing composite material:

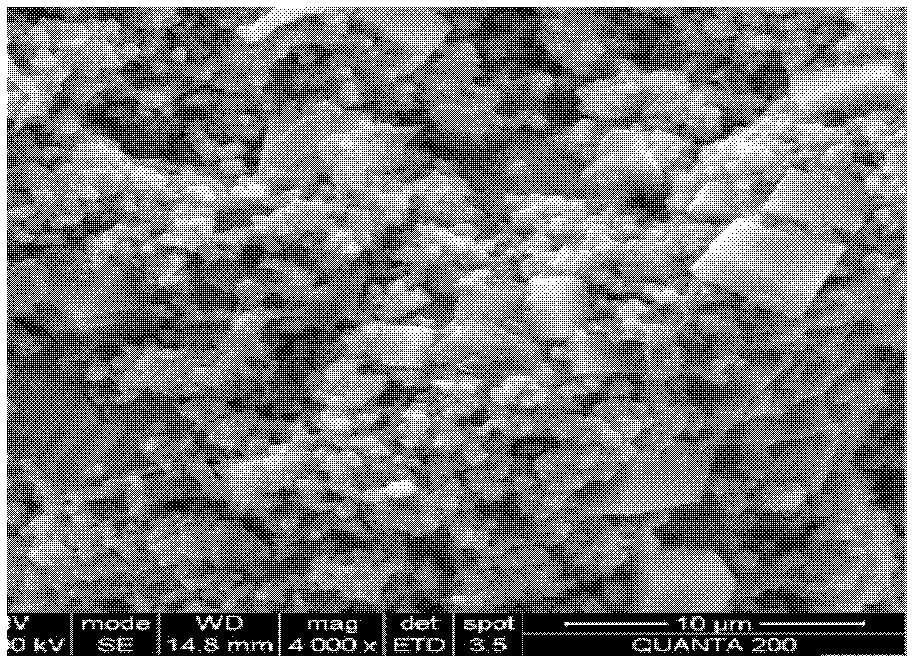

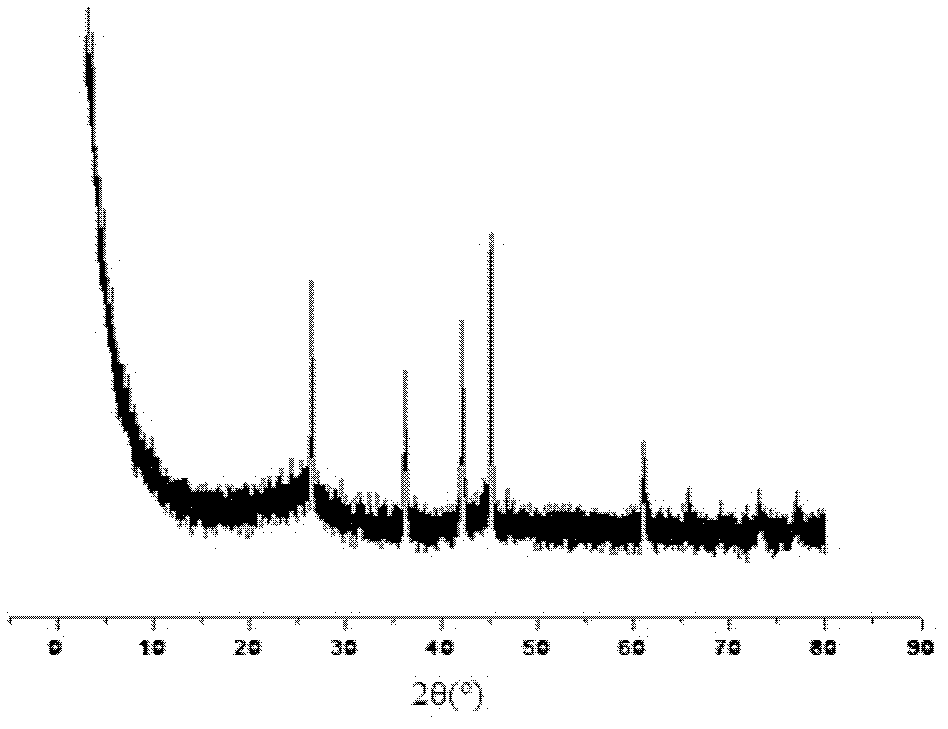

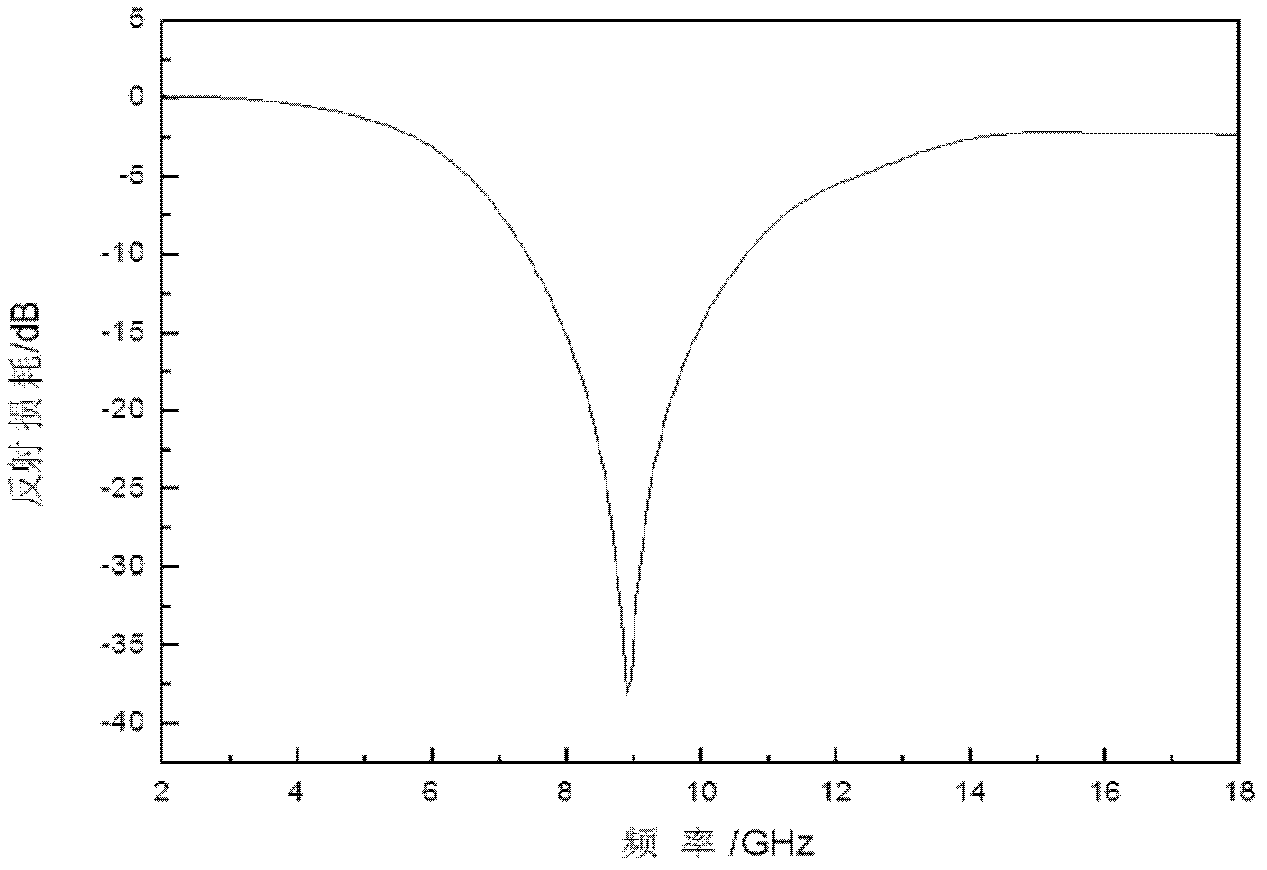

[0043] At 20°C, take 100g of activated carbon and put it in a beaker, add 10% (w / w) KH550 relative to the activated carbon and 100ml of absolute ethanol and stir evenly for surface adsorption. Then place the beaker in a 60°C water bath for ultrasonic dispersion for 2 hours, and then perform curing treatment in a tubular reactor at 80°C. The solidified sample was taken out and placed in a tubular reactor, and the temperature was raised to 900°C at a rate of 3°C / min and kept for 2 hours for carbonization treatment. Take it out at room temperature. The scanning electron microscope image of the composite material is shown in figure 1 As shown, the XRD diffraction pattern is as figure 2 as shown, figure 1 The medium cube is β-SiC crystal, and the small round particles are SiO 2 attached to the carbon substrate; figure 2 The peaks at 36°, 6...

Embodiment 3

[0045] With the tubular reactor described in embodiment 1 as reaction equipment, prepare C / SiO 2 / SiC absorbing composite material:

[0046] At 25°C, put 100g of activated carbon in a beaker, add 30% (w / w) TEOS and 100ml of absolute ethanol relative to the activated carbon, stir evenly, perform surface adsorption, and add 10ml of 5% (w / w) ammonia water , ultrasonically dispersed for 30 minutes, and then solidified in a tubular reactor at 120°C after standing overnight. The cured sample is taken out, ground and sieved into a 300-mesh powder and put into a tubular reactor, and the temperature is raised to 1000°C at a rate of 5°C / min for 1 hour for carbonization treatment, and the carbonized product is transferred to a high-temperature atmosphere furnace at a temperature of 15°C / min. The heating rate of min is 1400 ° C for 2 hours, and it can be taken out after cooling to room temperature. The scanning electron microscope effect and diffraction effect of the composite material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Return loss | aaaaa | aaaaa |

| Maximum reflection loss | aaaaa | aaaaa |

| Maximum reflection loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com