French leavened bread with rich dietary fibers and production method of French leavened bread

A technology with high dietary fiber and production methods, which is applied in the field of food processing, can solve the problems of odor, consumers are discouraged, rough taste, etc., and achieve the effect of increasing dietary fiber content, prolonging product shelf life, and avoiding rough taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

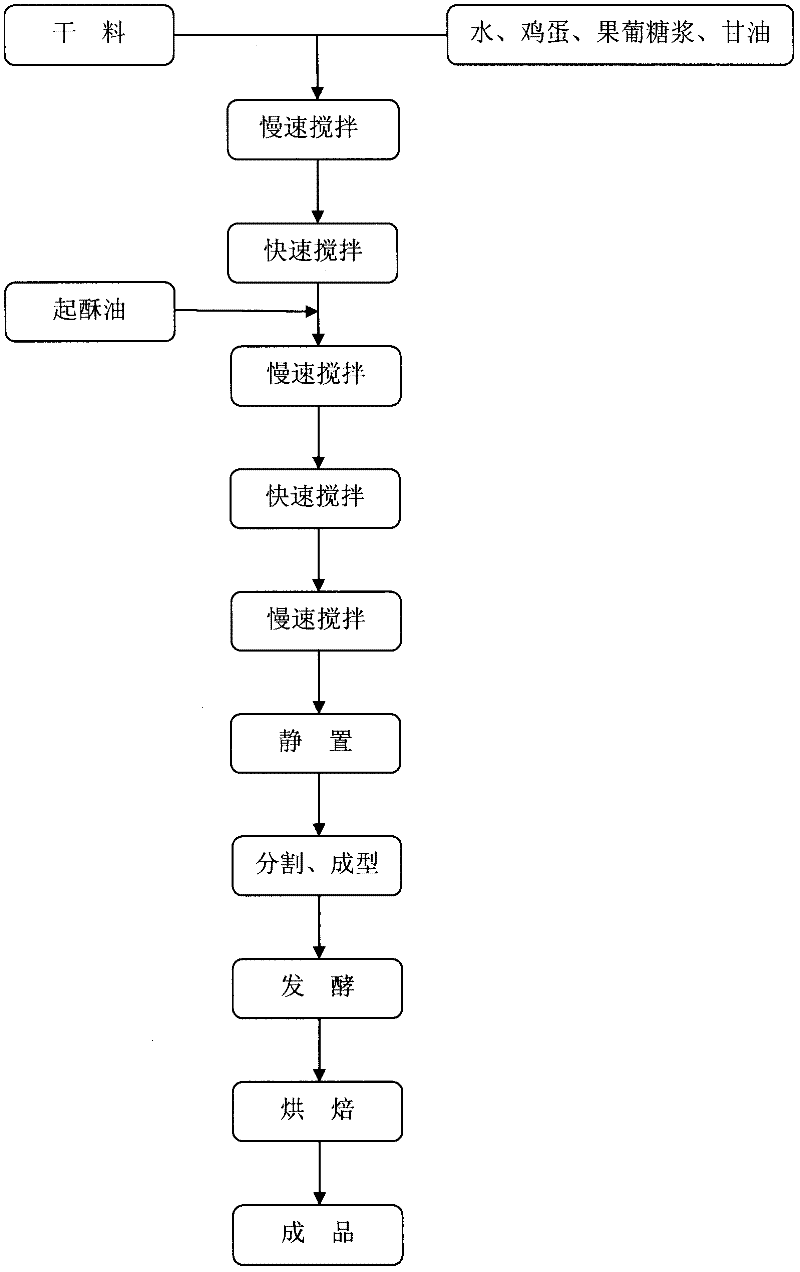

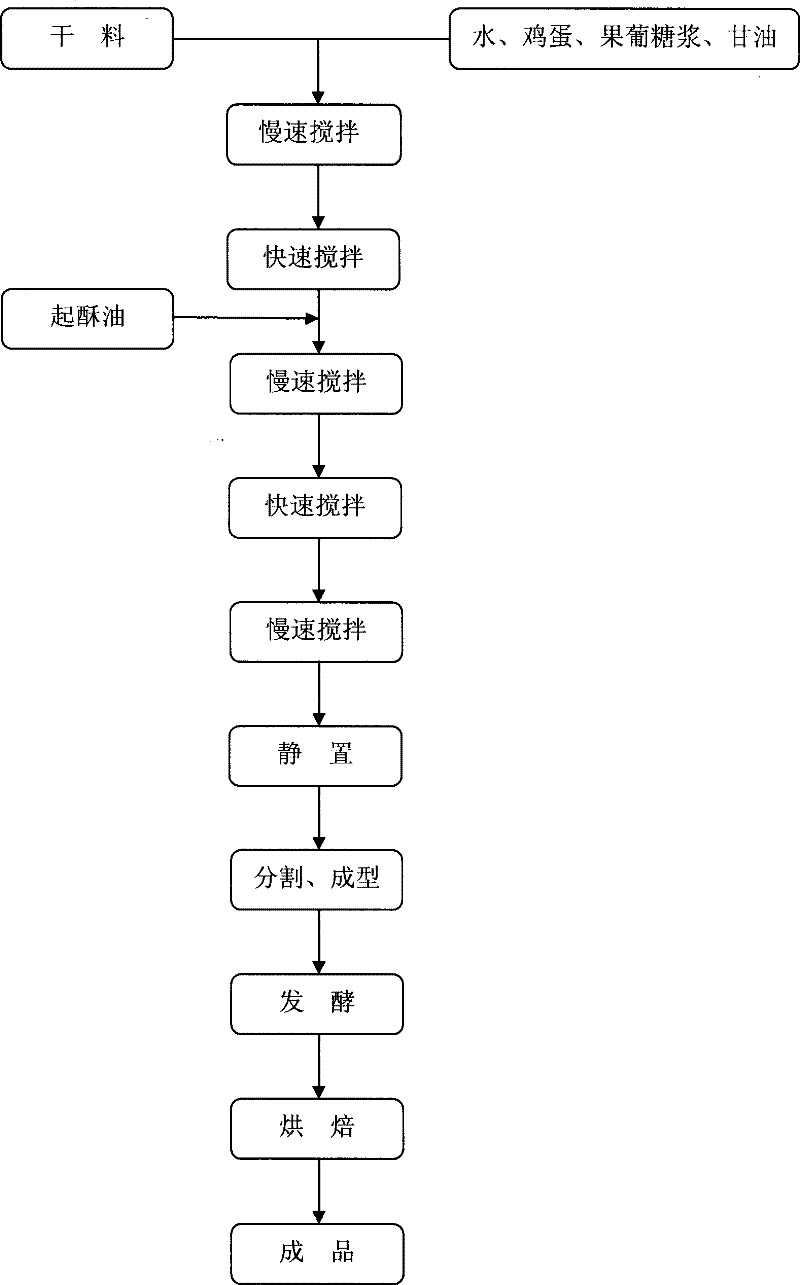

[0022] Embodiment one: a kind of production method of high dietary fiber French fermented bread, comprises following processing steps, and component ratio is counted in parts by weight:

[0023] (1) Mix 44.48 parts of high-gluten flour, 2.78 parts of soybean fiber powder, 8.34 parts of resistant starch, 1.39 parts of xylooligosaccharide, 0.83 parts of yeast, 5.56 parts of white sugar, 0.56 parts of salt, 1.67 parts of milk powder, α-amylase 0.00056 parts, 0.00056 parts of glucose oxidase, 0.0022 parts of pentosanase, 0.0028 parts of ascorbic acid, 0.22 parts of sodium stearoyl lactylate, 0.083 parts of carboxymethyl cellulose and 0.17 parts of hydroxypropyl methyl cellulose were put into the mixing tank, Stir slowly for 1 to 1.5 minutes, add 1.67 parts of fructose syrup, 1.67 parts of glycerin, 3.34 parts of whole egg liquid and 21.68 parts of water, stir slowly for 2 minutes, stir quickly for 2 minutes, then add 5.56 parts of shortening, stir slowly for 1 Minutes, fast stirri...

Embodiment 2

[0027] Embodiment two: a kind of production method of high dietary fiber French fermented bread, comprises following processing steps, and component ratio is counted in parts by weight:

[0028] (1) Mix 42.10 parts of high-gluten flour, 3.95 parts of soybean fiber powder, 6.58 parts of resistant starch, 1.05 parts of xylooligosaccharide, 0.79 parts of yeast, 5.79 parts of white sugar, 0.58 parts of salt, 1.58 parts of milk powder, α-amylase 0.00063 parts, 0.0007 parts of glucose oxidase, 0.0026 parts of pentosanase, 0.0032 parts of ascorbic acid, 0.32 parts of sodium stearoyl lactylate, 0.053 parts of carboxymethyl cellulose and 0.11 parts of hydroxypropyl methyl cellulose were put into the mixing tank, Stir slowly for 1.5 minutes, add 2.11 parts of fructose syrup, 2.11 parts of glycerin, 4.21 parts of whole egg liquid and 22.10 parts of water, stir slowly for 3 minutes, stir quickly for 3 minutes, then add 6.58 parts of shortening, stir slowly for 1.5 minutes, Stir rapidly fo...

Embodiment 3

[0032] Embodiment three: a kind of production method of French fermented bread with high dietary fiber comprises the following processing steps, and the component ratio is by weight parts:

[0033](1) Mix 39.97 parts of high-gluten flour, 4.99 parts of soybean fiber powder, 4.99 parts of resistant starch, 0.75 parts of xylooligosaccharides, 0.75 parts of yeast, 5.99 parts of white sugar, 0.60 parts of salt, 1.50 parts of milk powder, α-amylase 0.00070 parts, 0.00099 parts of glucose oxidase, 0.0030 parts of pentosanase, 0.0035 parts of ascorbic acid, 0.40 parts of sodium stearoyl lactylate, 0.025 parts of carboxymethyl cellulose and 0.05 parts of hydroxypropyl methyl cellulose were put into the mixing tank, Stir slowly for 1.2 minutes, add 2.50 parts of fructose syrup, 2.50 parts of glycerin, 4.99 parts of whole egg liquid and 22.48 parts of water, stir slowly for 2.5 minutes, stir quickly for 2.5 minutes, then add 7.49 parts of shortening, stir slowly for 1.2 minutes, Stir ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com