Method for removing sulfuryl fluoride by coupling plasma and chemical absorbing

A plasma and chemical absorption technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as secondary pollution, and achieve the effects of low operating costs, simple process flow, and health protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

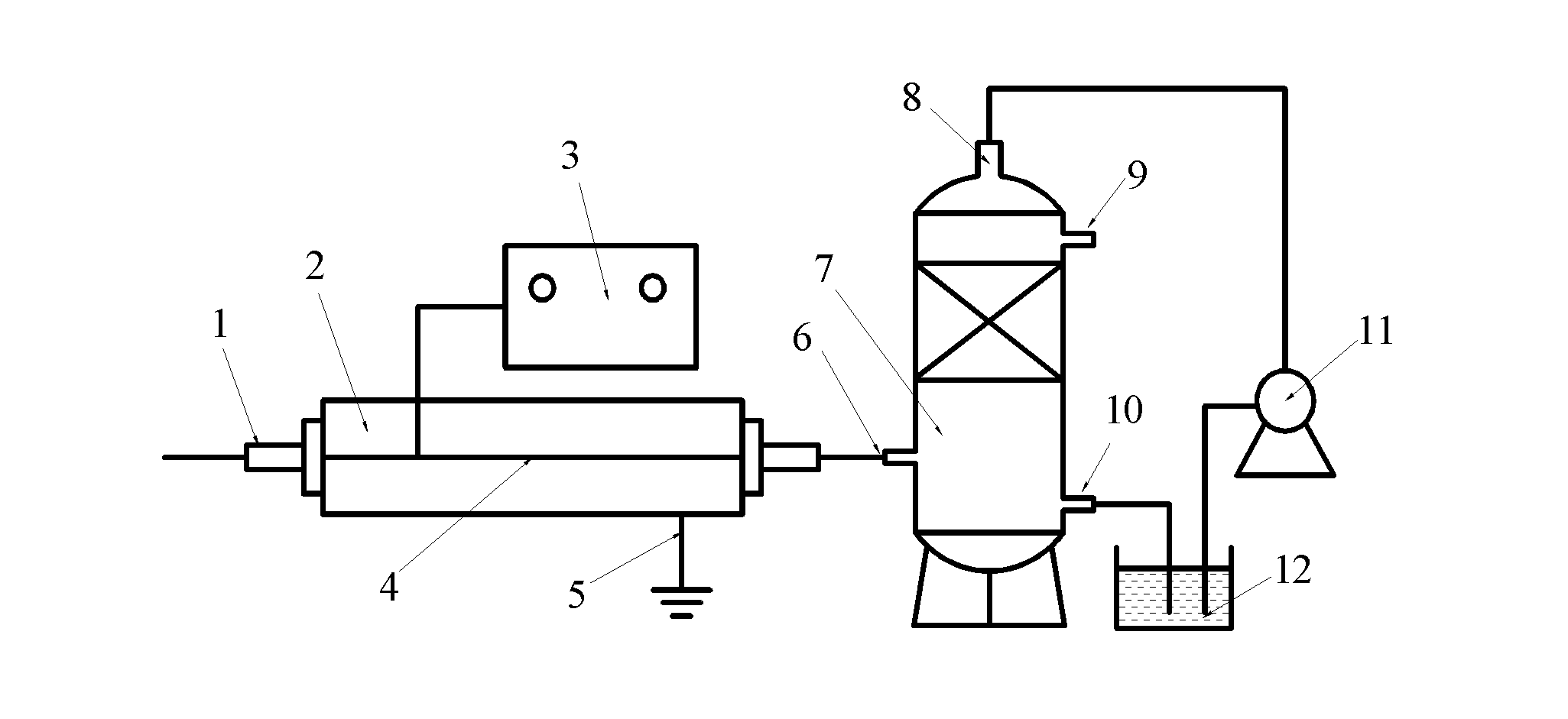

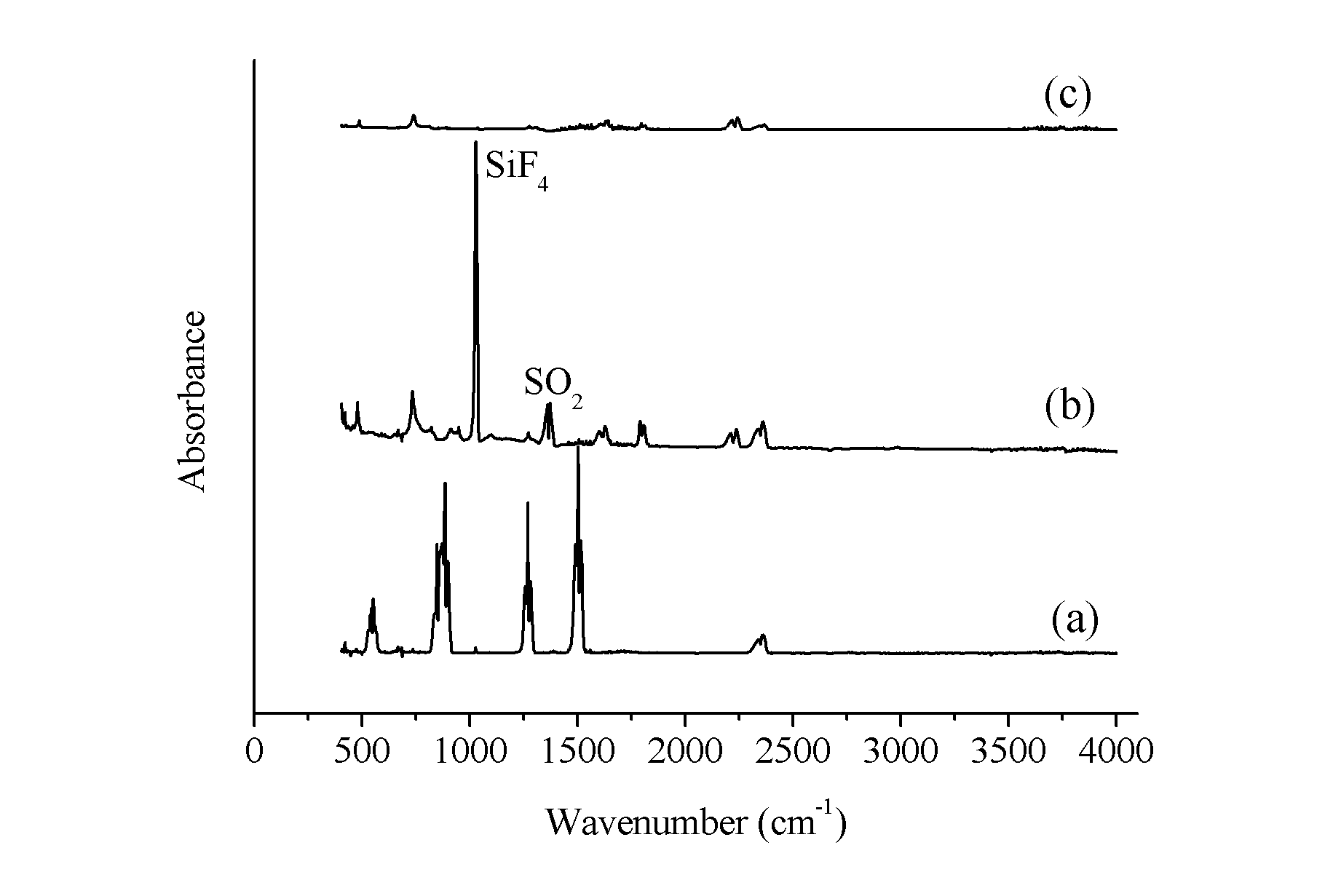

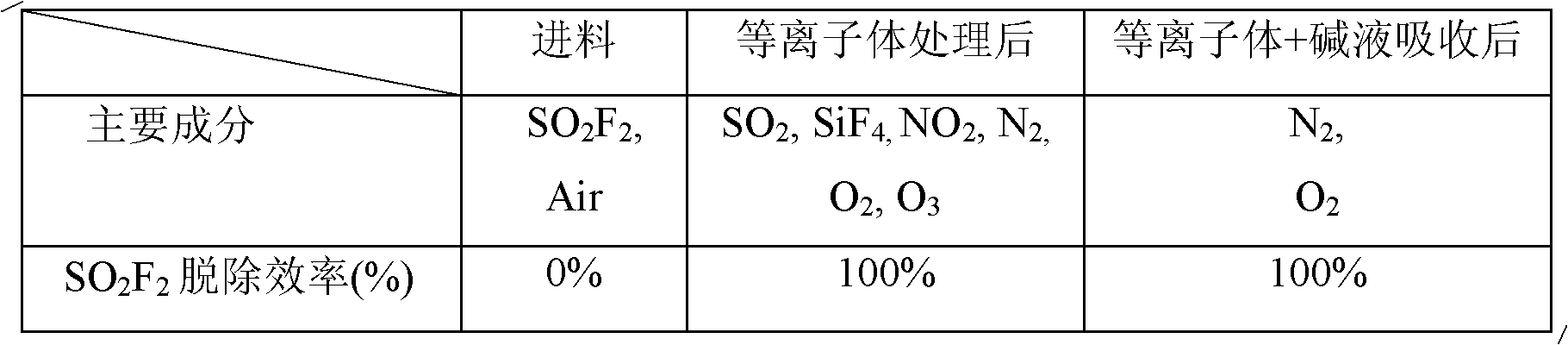

[0026] Example 1, in the experiment, the plasma reaction reactor adopts such as figure 1 In the line-barrel reactor shown, the discharge form adopts dielectric barrier discharge, the gas-liquid absorption tower is a packed tower with a diameter of 20mm and a height of 740mm, and the concentration of lye is 0.1mol / L NaOH solution. The plasma reactor consists of a quartz tube with an inner diameter of 35mm and a wall thickness of 2.5mm, a stainless steel rod discharge electrode, a stainless steel wire mesh ground electrode wrapped around the quartz tube, and 2-4mm quartz glass beads filled between the two discharge electrodes. Sulfuryl fluoride gas, plasma discharge gas products and products after lye absorption are analyzed by gas chromatography GC9790 equipped with FPD detector and Fourier transform infrared analyzer Nicolet. The detection sensitivity of gas chromatography is 1ppm, which is lower than the national emission standard ≤ 5ppm.

[0027] Discharge parameters: peak v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com