BCM (Biology Cilium Magnetic) biological sewage treatment system and BCM biological sewage treatment process

A sewage biological treatment and sewage technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of unsatisfactory denitrification effect, increased dosing amount, and construction cost Advanced problems, to achieve the effect of dissolved organic matter removal and denitrification, increase volume load, and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

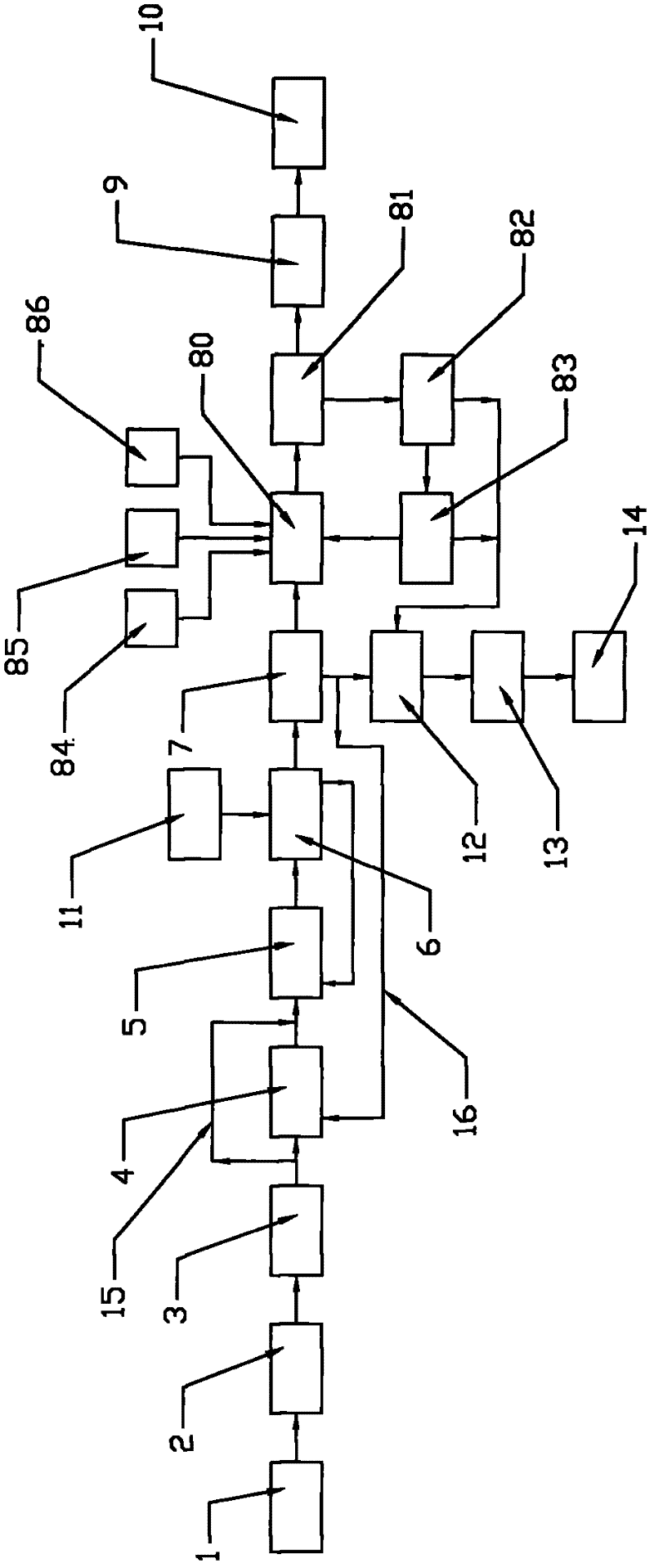

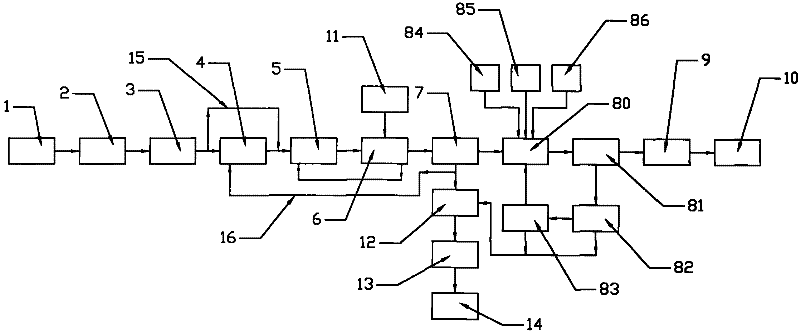

[0032] like figure 1 As shown, the BCM sewage biological treatment system in this embodiment includes a grid unit 2, a sand settling unit 3, a hydrolytic acidification unit 4, an anoxic unit 5, an aerobic unit 6, a sedimentation unit 7, and a quick mixing unit 80, which are fluidly connected in sequence. , fast sinking unit 81 and disinfection unit 9, the sludge outlet of the fast sinking unit 81 is connected with the sludge inlet of the sludge shearing unit 82, and the sludge containing magnetic powder outlet of the sludge shearing unit 82 is separated from the magnetic powder The sludge-containing magnetic powder inlet of the unit 83 is connected, the magnetic powder outlet of the magnetic powder separation unit 83 is connected with the magnetic powder inlet of the fast mixing unit 80, the sludge outlet of the settling unit 7, the sludge shearing unit 82 The sludge outlet of the sludge outlet and the sludge outlet of the magnetic particle separation unit 83 are respectively ...

Embodiment 2

[0036] Using the BCM sewage biological treatment process of the BCM sewage biological treatment system described in embodiment 1, urban sewage raw water (urban sewage raw water, COD Cr : 100-600mg / L, BOD 5 : 50-350mg / L, TN: 20-50mg / L, NH 3 -N: 20-40mg / L, TP: 1-6mg / L, SS: 50-500mg / L) through the following processing units in turn:

[0037] (a) Grid unit 2: the grid gap is 10mm;

[0038] (b) Grit Settlement Unit 3: The residence time of sewage in the Grit Settlement Unit 3 is 30s, then enters the Hydrolysis Acidification Unit 4 and the Anoxic Unit 5 respectively, and from the Grit Settlement Unit 3 enters the Hydrolysis Acidification Unit 4 and the Anoxic Unit respectively 5 The proportion of sewage volume is 4:1;

[0039] (c) Hydrolysis and acidification unit 4: The sewage stays in the hydrolysis and acidification unit 4 for 1-2 hours, the sludge concentration is 2000-5000 mg / L, and the sewage enters the anoxic unit 5 after effluent from the hydrolysis and acidification unit...

Embodiment 3

[0047] The BCM sewage biological treatment process of the present invention is used to treat the raw water of urban sewage plants to the first-class A standard.

[0048] Urban sewage raw water, daily treatment capacity 100m 3 / d, COD Cr : 300mg / L, BOD 5 : 130mg / L, TN: 38mg / L, NH 3 -N: 26 mg / L, TP: 2.6 mg / L, SS: 90 mg / L.

[0049] The residence time of the sewage in the hydrolytic acidification unit 4 is 1 hour, and the residence time in the anoxic unit 5 is 2.85 hours. The residence time in the aerobic unit 6 is 6.06h, and the filler is made of fiber, and the volume of the filler made of fiber accounts for 60% of the total volume of the aerobic unit 6 . Sedimentation unit 7 surface load 1.0m 3 / m 2 h, sewage residence time 2.2h. The reflux ratio of the nitrifying liquid is 100%, and the aerobic unit 6 returns to the anoxic unit 5 . The sludge reflux ratio is 50%, and the sludge is returned from the precipitation unit 7 to the hydrolysis acidification unit 4. Precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com