Battery diaphragm and preparation method thereof

A technology for battery separators and porous membranes, applied in the field of battery separators and their preparation, can solve the problems of weak interlayer bonding, lower ion transmission rate, and easy detachment of laminated membranes, and achieve long service life and good closed cell protection Function, the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

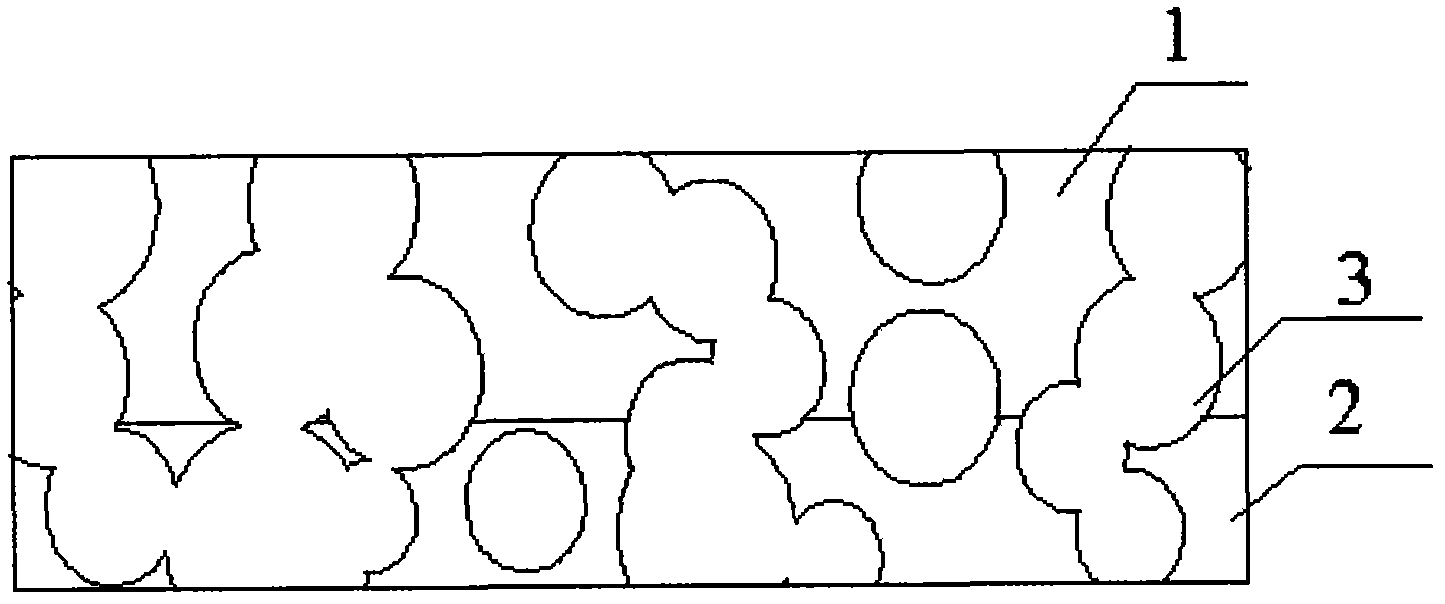

Image

Examples

preparation example Construction

[0053] The preparation method of the battery diaphragm provided by the invention comprises the following steps:

[0054] (1) Add binary organic acid anhydride and organic diamine to a solvent whose mass is 4-9 times the total mass of binary organic acid anhydride and organic diamine at a molar ratio of 0.7-1.4:1, and simultaneously add a mass of binary organic A pore-forming substance that is 0.02-0.2 times the total mass of acid anhydride and organic diamine is stirred at 30-60°C for 4-20 hours to obtain a viscous mixture with an intrinsic viscosity [η] = 100-200 ml / g ;

[0055] (2) At 30-65°C, coat the mixture obtained in step (1) on a stainless steel plate with a thickness of 200-400 microns, and then dry at 30-130°C for 5-10 minutes to remove Solvent, obtain polyamic acid film;

[0056] (3) adopting the mode of gradient temperature rise, the polyamic acid film obtained in step (2) is heated in nitrogen to carry out imidization, obtains the polyimide film of 20-40 microns...

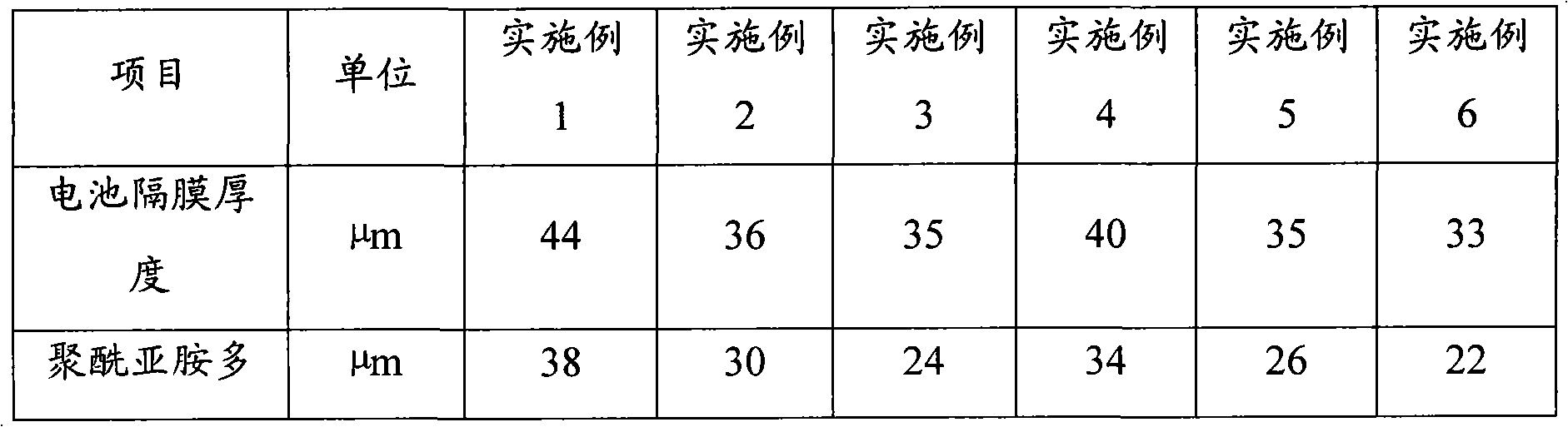

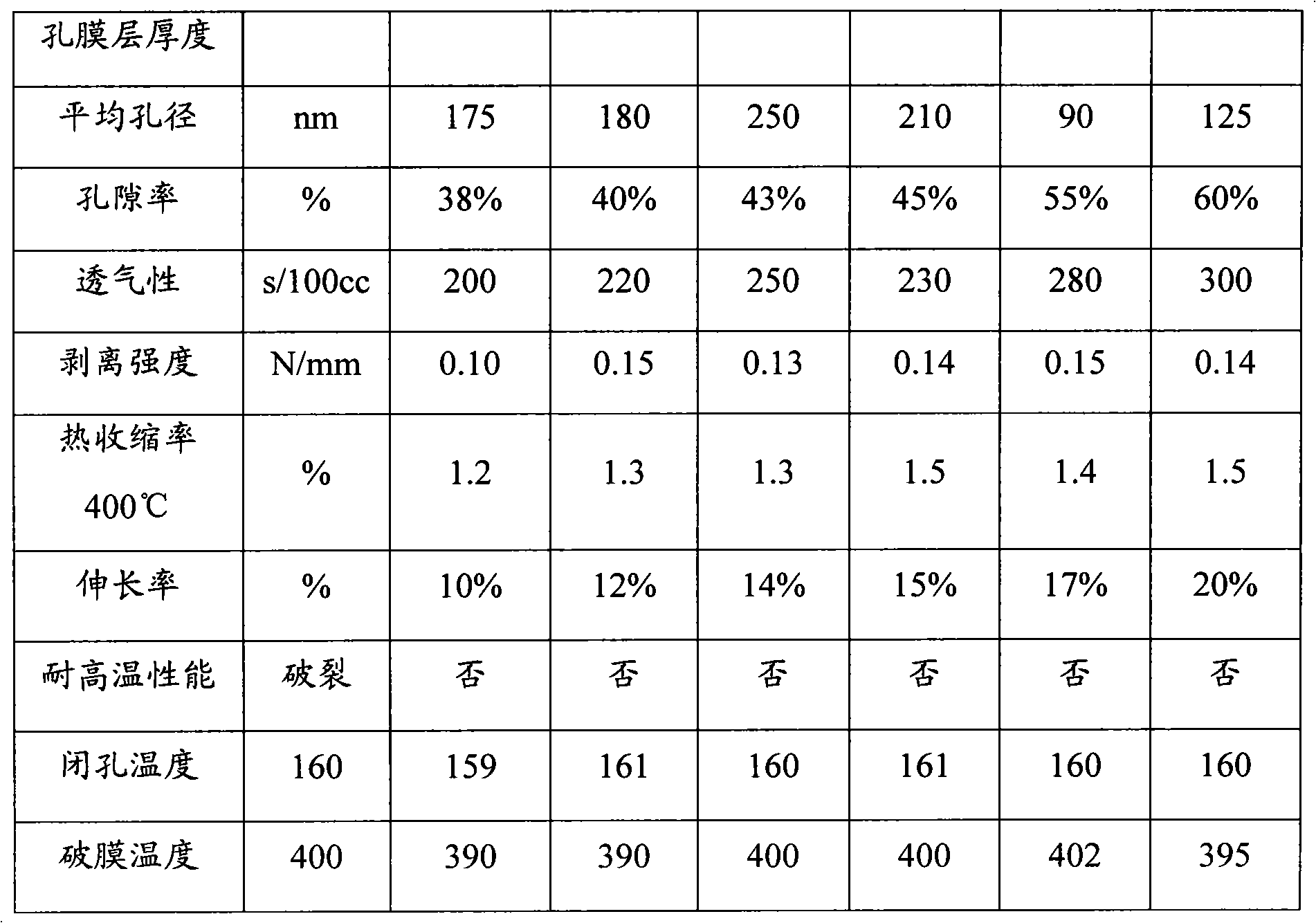

Embodiment 1

[0062] (1) Biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether are added to the total mass of biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether at a molar ratio of 1.1:1. In the N-2-methylpyrrolidone of 4 times of quality, add the calcium hydroxide (average particle size is 1.5 microns) that quality is biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether total quality 0.02 times simultaneously, Stirring at 35°C for 6 hours gave a viscous mixture with an intrinsic viscosity [η]=150 ml / g;

[0063](2) Coating the mixture obtained in step (1) on a stainless steel plate at 30°C, the thickness of the coating layer is 350 microns, and then drying at 120°C for 5 minutes to remove the solvent to obtain a polyamic acid film;

[0064] (3) The polyamic acid film obtained in step (2) is heated in nitrogen to carry out imidization by means of gradient temperature rise to obtain a polyimide non-porous film of 38 microns. The heating method is: ke...

Embodiment 2

[0068] The battery separator is prepared as described in Example 1, wherein the quality of calcium hydroxide (with a particle size of 1.5 microns) in step (1) is the total mass of biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether 0.04 times, the intrinsic viscosity of the viscous mixture of gained is [η]=160 milliliters / gram; Adjust the coating layer thickness of polyamic acid membrane, the thickness of the polyimide nonporous membrane of gained is 30 microns, finally obtained The thickness of the battery separator is 36 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com