Clean production method for functional compound feed and product by clean production method

A compound feed, clean production technology, applied in animal feed, animal feed, food processing and other directions, can solve the problem of drug resistance of harmful bacteria and drug residues in animal products, improve comprehensive utilization rate, improve immunity, reduce antibiotics the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

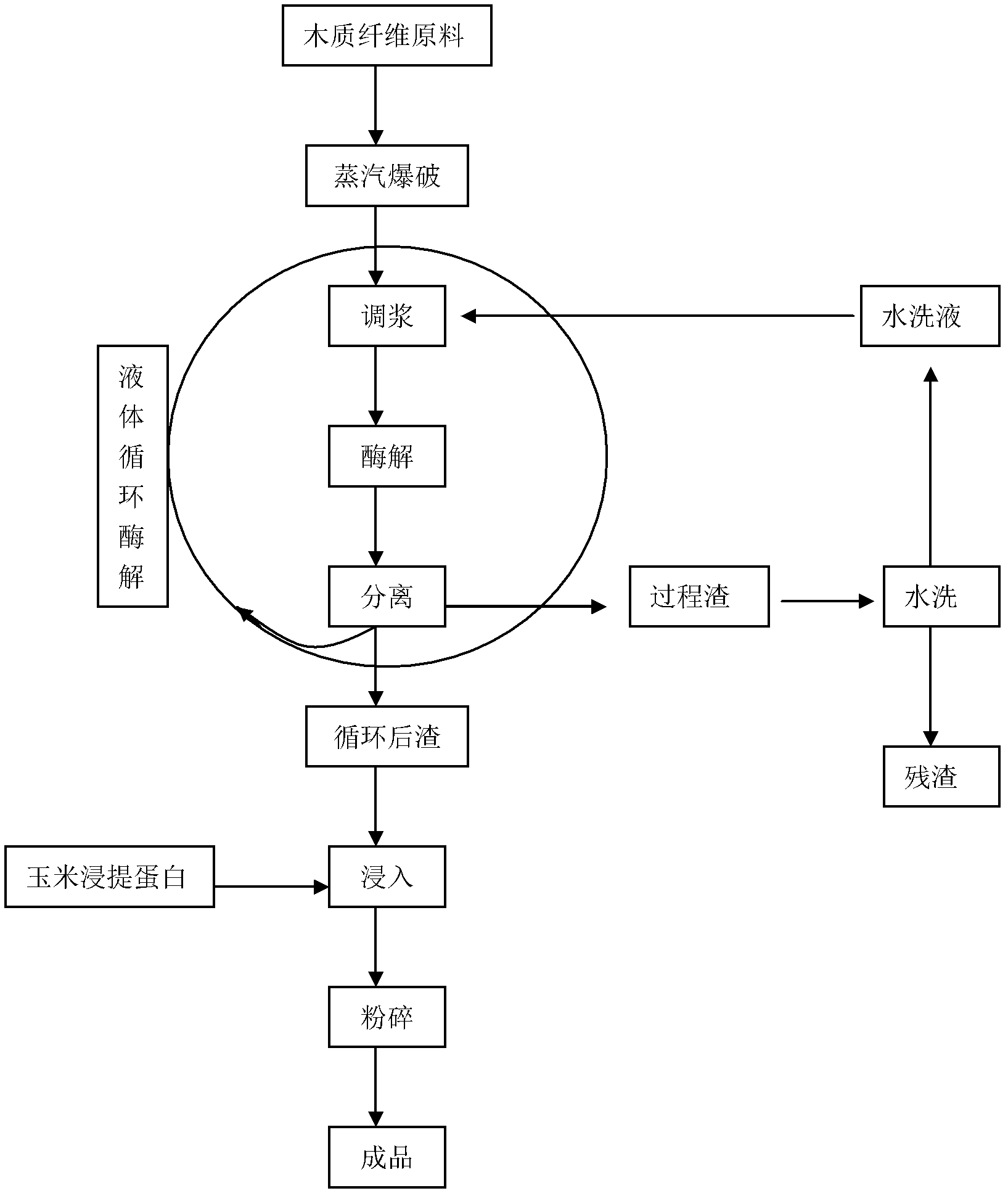

Method used

Image

Examples

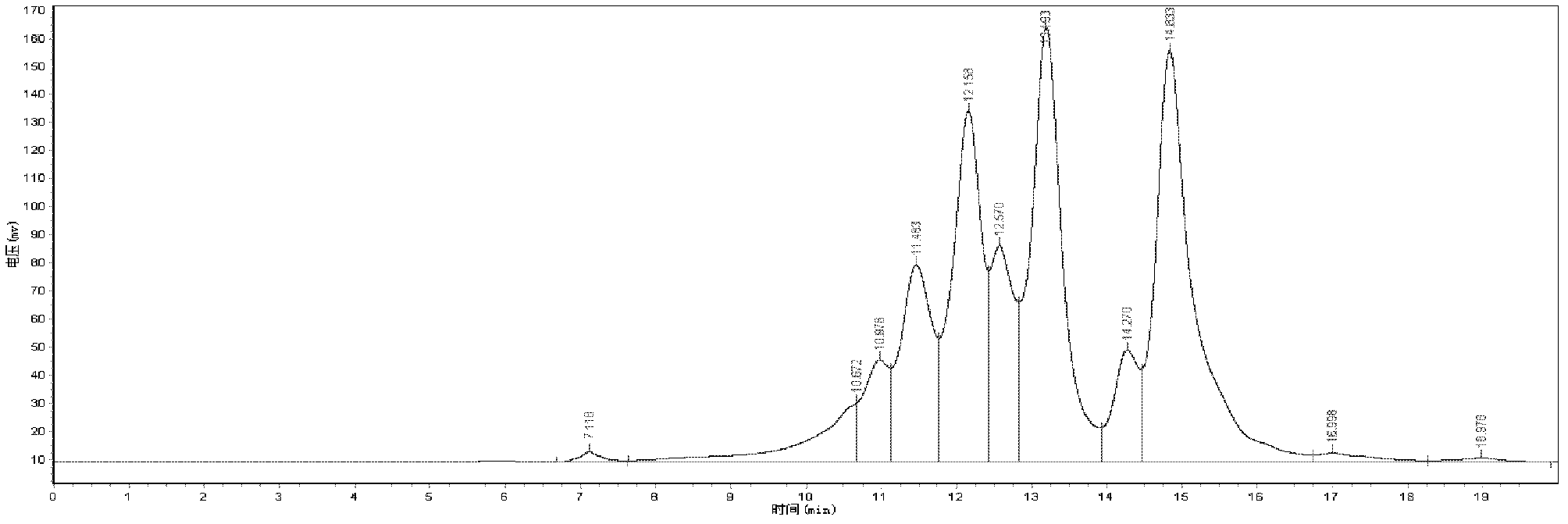

Embodiment 1

[0036] 1. Steam explosion pretreatment

[0037] The explosion cavity of the steam explosion machine is 5000ml, the blasting condition is 2.0Mpa; the blasting time is 30s.

[0038] 2. Mixing

[0039] Weigh 50 g of bagasse after steam explosion, adjust the reaction system according to the solid-liquid ratio of 1:8, make three parallel samples, and set aside.

[0040] 3. Enzyme hydrolysis

[0041] Adjust the pH value of the prepared reaction system to 4.5, preheat at 50°C, add xylanase in an amount of 10ug / 100ml, and stir at 50°C for 8h.

[0042] 4. Slag liquid separation

[0043] The sample after enzymatic hydrolysis is filtered with a vacuum pump to ensure that the filtrate is fully filtered, and the filter cake is washed with water to ensure the maximum collection of sugar. Record the measured volume of the filtrate and place it in a beaker for later use.

[0044] 5. Filtrate recycling

[0045] Use the filtrate obtained in step 4 and the steam-exploded bagasse to adjust ...

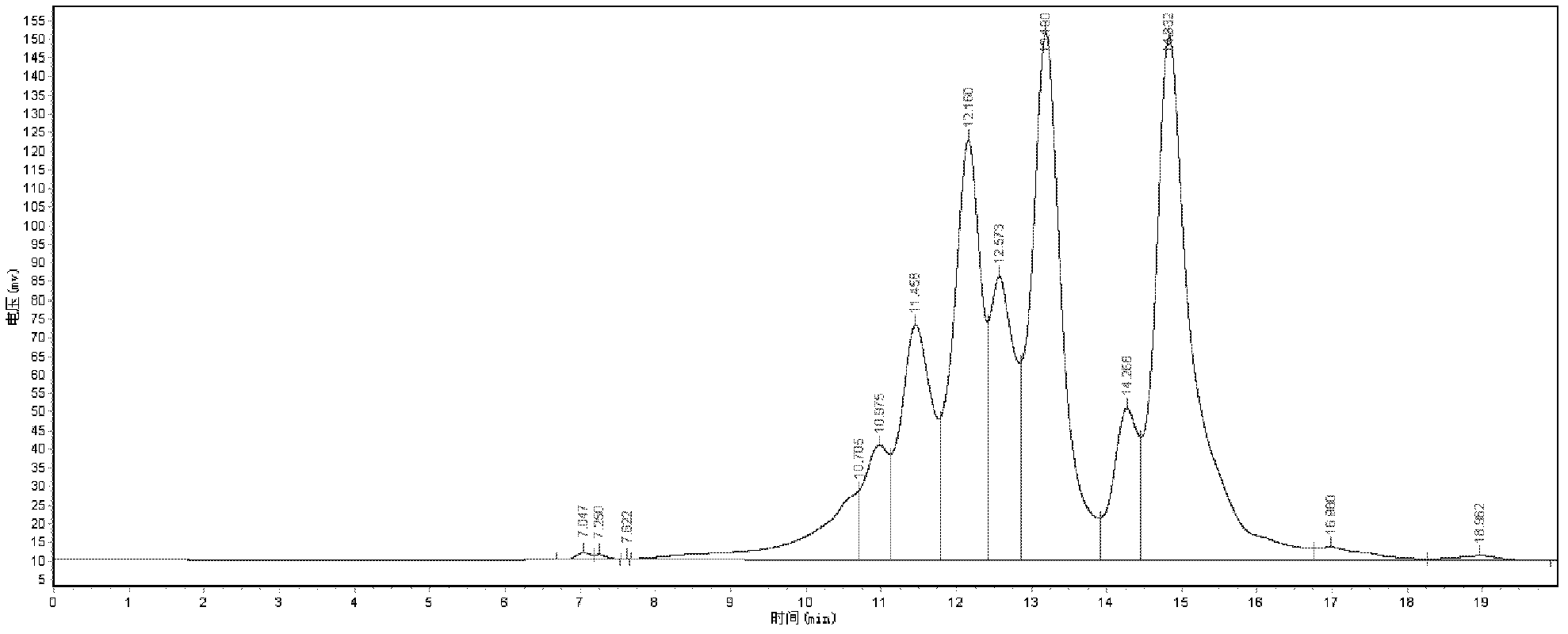

Embodiment 2

[0063] 1. Steam explosion pretreatment

[0064] The explosion cavity of the steam explosion machine is 5000ml, the blasting condition is 2.5Mpa; the blasting time is 45s.

[0065] 2. Mixing

[0066] Weigh 350 g of corn cobs after steam explosion, adjust the reaction system according to the solid-liquid ratio of 1:4, and set aside.

[0067] 3. Enzyme hydrolysis

[0068] Adjust the pH value of the prepared reaction system to 5, preheat at 55°C, add xylanase in an amount of 15ug / 100ml, and stir and enzymatically hydrolyze at 50°C for 8h.

[0069] 4. Slag liquid separation

[0070] The sample after enzymatic hydrolysis is filtered with a vacuum pump to ensure that the filtrate is fully filtered, and the filter cake is washed with water to ensure the maximum collection of sugar. Record the measured volume of the filtrate and place it in a beaker for later use.

[0071] 5. Filtrate recycling

[0072] Use the filtrate obtained in step 4 and the steam-exploded bagasse to adjust ...

Embodiment 3

[0087] 1. Steam explosion pretreatment

[0088] The explosion cavity of the steam explosion machine is 5000ml, the blasting condition is 2.0Mpa; the blasting time is 60s.

[0089] 2. Mixing

[0090] Weigh 500 g of bagasse after steam explosion, adjust the reaction system according to the solid-to-liquid ratio of 1:6, and set aside.

[0091] 3. Enzyme hydrolysis

[0092] Adjust the pH value of the prepared reaction system to 5, preheat at 50°C, add xylanase in an amount of 10ug / 100ml, and stir at 50°C for 8h.

[0093] 4. Slag liquid separation

[0094] The sample after enzymatic hydrolysis is filtered with a vacuum pump to ensure that the filtrate is fully filtered, and the filter cake is washed with water to ensure the maximum collection of sugar. Record the measured volume of the filtrate and place it in a beaker for later use.

[0095] 5. Filtrate recycling

[0096] Use the filtrate obtained in step 4 and the steam-exploded bagasse to adjust the reaction system at a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com