Preparation method of carotenoid emulsion and microcapsules

A technology of carotene and microcapsules, which is applied in the fields of food, health food processing and medicine, can solve the problems of being unable to meet the requirements of the development of food ingredients and reducing the ability to adapt to the environment, achieve good biocompatibility, and the preparation method is simple and easy , The effect of less loss of carotenoids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

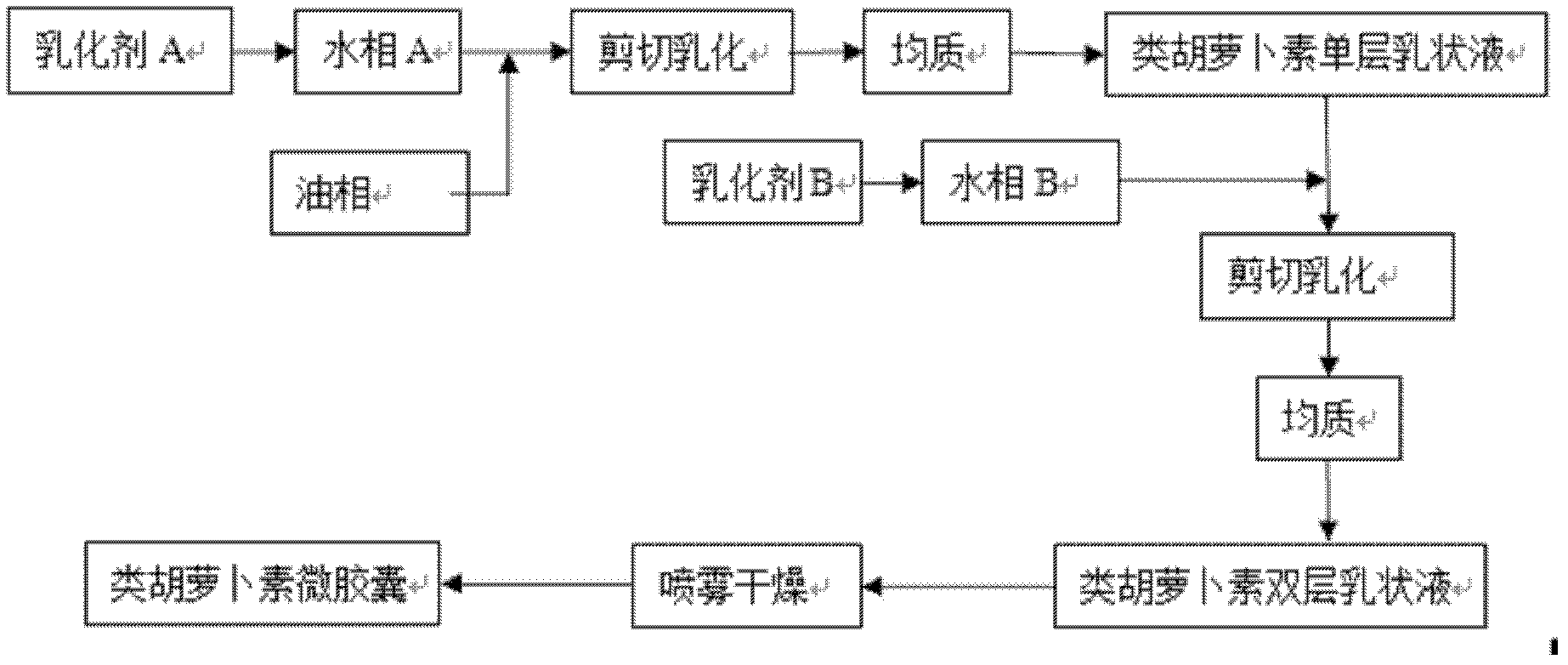

Method used

Image

Examples

Embodiment 1

[0035] 1) Weigh 13.33 g of lycopene vegetable oil suspension with a mass percentage of lycopene of 30%, 18.5 g of edible olive oil, 0.05 g of antioxidant vitamin C palmitate and 0.05 g of vitamin E, and mix them while heating , when the temperature rises to 140 degrees, keep it for 1 minute, and the oil phase is obtained after the lycopene is fully dissolved;

[0036] 2) The oil phase is immediately transferred to 200g of water phase A containing gum arabic (5%), the temperature is controlled at 70°C, high-speed shearing is carried out, the speed is controlled at 10000 rpm, and the time is 10min, and then transferred to high-pressure homogenization In the quality machine, cycle three times, the homogeneous pressure reaches 25MPa, obtain lycopene monolayer emulsion;

[0037] 3) Slowly add the lycopene monolayer emulsion obtained in step 2) into the aqueous phase B containing 200 g of chitosan (1.25%), and transfer it to a high-pressure homogenizer after high-speed shearing for ...

Embodiment 2

[0039]1) Weigh 13.33 grams of β-carotene emulsifiable oil with a mass percentage of β-carotene of 30%, 5 grams of edible soybean oil, 0.5 grams of vitamin C palmitate, and 0.5 grams of vitamin E, mix while heating, and heat up To 160°C, keep for 5 minutes to obtain the oil phase;

[0040] 2) Immediately transfer the oil phase to 200g of water phase A containing soybean polysaccharide (8%), shear at high speed, control the speed at 10,000 rpm for 10 minutes, control the temperature at 50°C, and then transfer to high-pressure homogenization In the machine, cycle three times, homogeneous pressure 60MPa, obtain β-carotene monolayer emulsion;

[0041] 3) Slowly add the β-carotene monolayer emulsion obtained in step 2) into 200g of water phase B containing chitosan (2%), and emulsify and stir with high speed shearing for 10 minutes while adding, then turn to high pressure The homogenizer circulates 3 times, the pressure is controlled at 80MPa, and the carotene double-layer emulsion...

Embodiment 3

[0044] 1) Take by weighing 26.67 grams of 30% β-carotene emulsifiable oil, 4.33 grams of edible olive oil, 0.5 grams of vitamin C palmitate, and 0.5 grams of vitamin E, and mix while heating, and heat up To 140°C, keep for 5 minutes to obtain the oil phase;

[0045] 2) Immediately transfer the oil phase to 200g of water phase A containing soybean polysaccharide (10%), high-speed shearing, speed control at 10000 rpm, time 10min, temperature control at 70°C, and then transfer to high-pressure homogenization In the machine, cycle three times, the homogeneous pressure reaches 60MPa, and obtain β-carotene monolayer emulsion;

[0046] 3) Slowly add the β-carotene single-layer emulsion obtained in step 2) into the aqueous phase B containing chitosan (2.5%), emulsify and stir with high-speed shear while adding, and after 10 minutes, transfer to high-pressure homogenization The quality machine was circulated 6 times, and the pressure was controlled at 80MPa to obtain a double-layer em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com