Method for preparing ethylene-tetrafluoroethylene copolymers

A technology of tetrafluoroethylene and copolymers, which is applied in the field of fluorine-containing polymer materials, can solve the problems of difficult recovery of synthetic solvents, long reaction time, and low product output, and achieve excellent physical and chemical properties, improve physical properties, and high output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

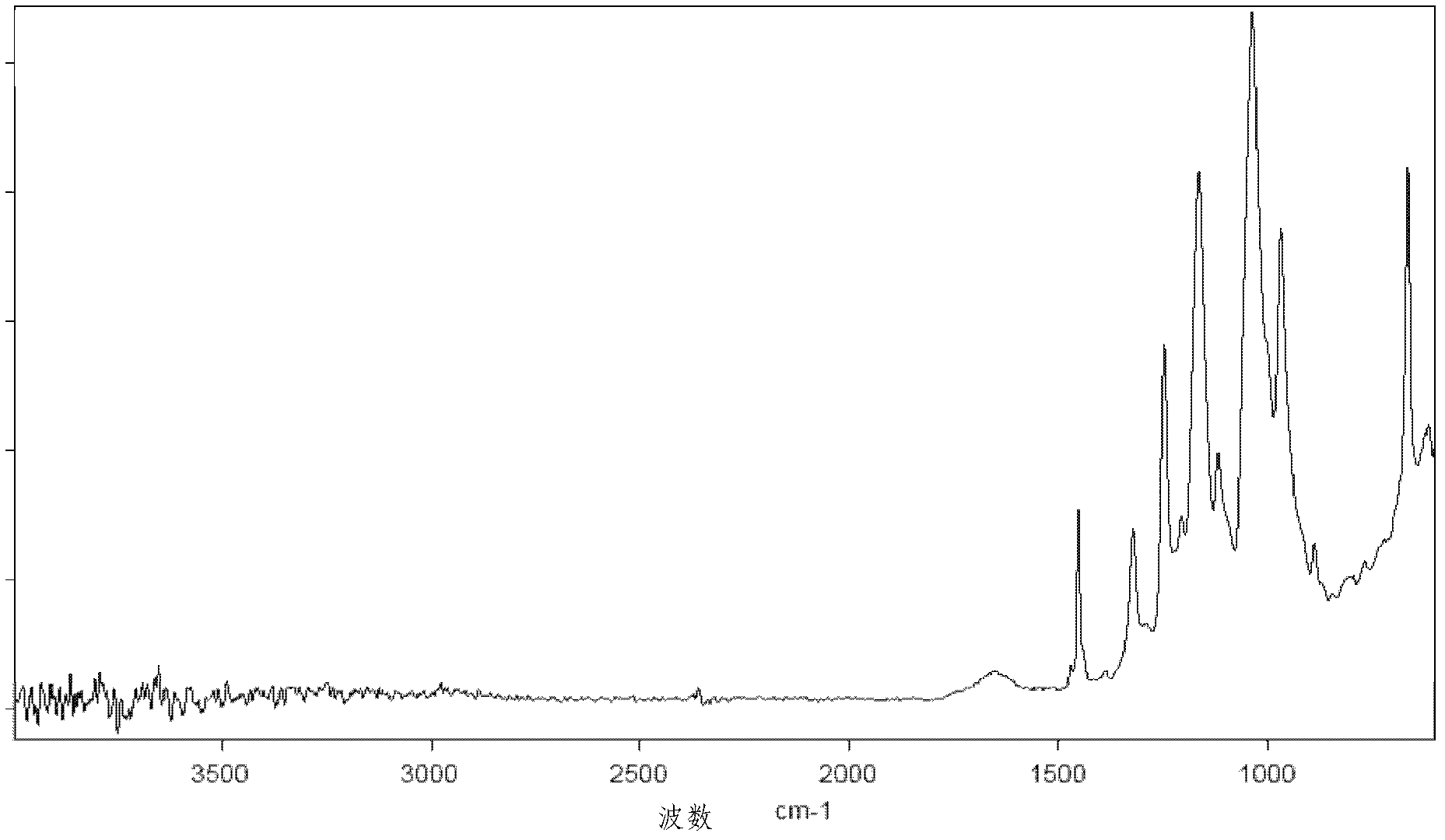

Image

Examples

Embodiment 1

[0033] In a 10L stainless steel vertical reaction kettle, add 6000g of perfluorocyclohexane, blow nitrogen and exhaust oxygen three times, evacuate to oxygen content of 13ppm, add CF 3 O(CF(OCF 3 ) CF 2 O) 6 (CF 2 OO)COONH 4 10g, sodium dihydrogen phosphate 8g, pentane 3ml, start stirring, speed 200rpm, heat up to 40°C, add ethylene, tetrafluoroethylene, perfluoropropylene (35 / 50 / 15mol%) to 4.0MPa, add perfluorodihexyl 5g of peroxide, continuous addition of mixed monomers of ethylene and tetrafluoroethylene (48 / 52mol%) to keep the pressure of the reactor at 4.0MPa, and unreacted monomers were recovered after 4 hours of reaction to obtain 1.1Kg of ETFE polymer. Product performance indicators are shown in Table 2.

[0034] Table 2 Product Performance Index

[0035] Test items

Embodiment 2

[0037] In a 10L stainless steel vertical reaction kettle, add 6000g of perfluorocyclohexane, blow nitrogen and exhaust oxygen three times, evacuate to oxygen content of 19ppm, add CF 3 O(CF(OCF 3 ) CF 2 O) 6 (CF 2 OO)COONH 4 10g, sodium dihydrogen phosphate 8g, pentane 3ml, start stirring, speed 200rpm, heat up to 40°C, add ethylene, tetrafluoroethylene, perfluoromethyl vinyl ether mixed monomer (40 / 50 / 10mol%) to 4.0 MPa, add perfluorodihexyl peroxide 5g, continuously add ethylene, tetrafluoroethylene (48 / 52mol%) mixed monomer to keep the reactor pressure 4.0MPa, reclaim the unreacted monomer after reacting for 6h, get ETFE polymer 1.2 Kg. The performance indicators of polymers are shown in Table 3.

[0038] Table 3 Product Performance Index

[0039] Test items

Embodiment 3

[0041] In a 10L stainless steel vertical reaction kettle, add 6000g of perfluorocyclohexane, blow nitrogen and exhaust oxygen three times, evacuate to oxygen content of 19ppm, add CF 3 O(CF(OCF 3 ) CF 2 O) 6 (CF 2 OO)COONH 4 10g, sodium dihydrogen phosphate 8g, pentane 3ml, start stirring, speed 200rpm, heat up to 40°C, add ethylene, tetrafluoroethylene, perfluoropropylene, perfluoromethyl vinyl ether mixed monomer (40 / 50 / 8 / 2mol%) to 4.0MPa, add 5g of perfluorodihexyl peroxide, continuously add ethylene, tetrafluoroethylene (48 / 52mol%) mixed monomer to keep the pressure of the reactor at 4.0MPa, and recover the unreacted monomer after reacting for 8h , to obtain 1.1Kg of ETFE polymer. The performance indicators of polymers are shown in Table 4.

[0042] Table 4 Product performance indicators

[0043] Test items

[0044] Through Examples 1 to 3, by adding different modified monomers, the performance index requirements of the product can be met, but after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com