Fermentation culture of Bacillus vallismortis and production method of compound microbial fertilizer

A technology of Bacillus dead valley and complex microorganisms, which is applied in the field of microbial fermentation and cultivation, can solve the problems of farmland soil deterioration, quality reduction, and fertility decline, and achieve the effects of increasing soil moisture content, reducing disposal costs, and comprehensive nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

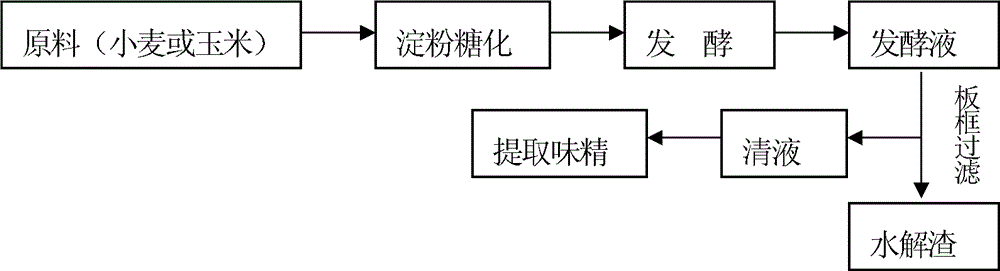

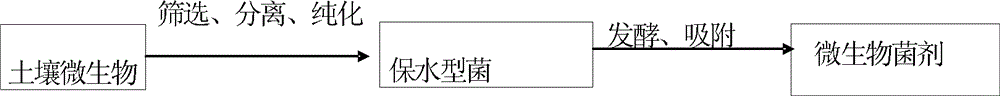

Method used

Image

Examples

Embodiment 1

[0040] 1. Strain fermentation: the basic medium is sodium glutamate 10g / L, MgSO 4 ·7H 2 O 0.25g / L, CaCl 2 2H 2 O 0.1g / L, K 2 HPO 4 When 2g / L, the fermentation conditions of the Bacillus dead valley strain are: temperature 32°C, liquid volume 20%, medium initial pH 6.5, yeast extract as nitrogen source, dosage 5g / L, saccharified corn flour as carbon source, fermented at a dosage of 15g / L, and the amount of bacteria obtained after 48 hours of fermentation was 3.9×10 10 CFU / mL;

[0041] 2. Sampling of amino acid waste: the hydrolyzed slag was obtained from Henan Lianhua Amino Acid Co., Ltd.;

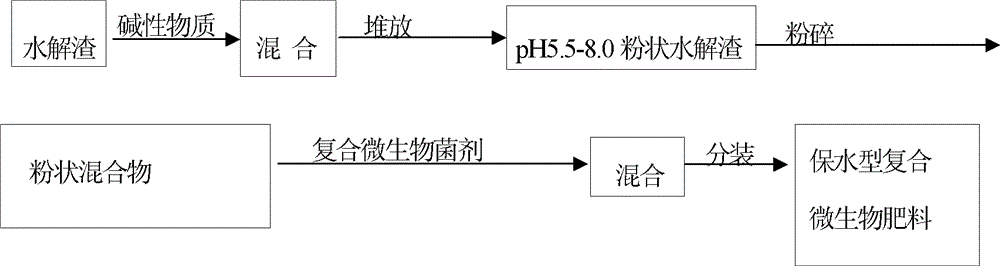

[0042] 3. pH adjustment: Add 8% potassium hydroxide to the hydrolyzed slag, mix it, crush it to 80 mesh with a chain crusher, and stack it for 8-12 hours to allow it to fully react. The basic properties of hydrolyzed slag after treatment are shown in Table 1;

[0043] Table 1 Basic properties of hydrolyzed slag (powder) after treatment

[0044]

[0045] 4. Turn over: Use a fork...

Embodiment 2

[0057] The fermentation conditions of the strain are as follows: temperature 30°C, liquid volume 25%, medium initial pH 7.0, yeast extract as the nitrogen source, the dosage is 10g / L, saccharified corn flour is the carbon source, and the dosage is 20g / L. After 48 hours of fermentation, the amount of bacteria that can be obtained is 4.5×10 10 CFU / mL;

[0058] Add 6% potassium hydroxide to the hydrolyzed slag, mix it, crush it to 100 mesh with a chain crusher, and stack it for 15 hours to allow it to fully react;

[0059] In the preparation of microbial inoculum, the fineness of rice husk powder is 100 mesh, and the adsorption mass ratio of inoculum to rice husk powder is 1:5. The three adsorbed single bacterial agents were mixed according to the mass ratio of Bacillus dead valley: Bacillus subtilis: Bacillus jelly-like = 10:3:7.

[0060] The addition ratio of the bacterial agent is 6%, and the addition ratio of the hydrolyzed slag is 64%, both of which are the mass percentage...

Embodiment 3

[0062] Add 6% potassium hydroxide to the hydrolyzed slag, mix it with a chain crusher to 120 mesh, and stack it for 8-12 hours to allow it to fully react;

[0063] In the preparation of water-retaining composite microbial agent, the fineness of rice husk powder is 120 mesh, and the adsorption ratio of bacterial liquid to rice husk powder is 1:4. The three kinds of single bacterial agents adsorbed respectively are mixed according to the mass ratio of Bacillus dead valley: Bacillus subtilis: Bacillus jelly-like = 15:10:7, and then pulverized to 80 mesh.

[0064] The addition ratio of the bacteria agent is 8%, the addition ratio of the hydrolyzed slag is 63%, and the addition ratio of urea is 14%, all of which are the mass percentages of the final finished fertilizer. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com