Method for preparing metallized pellets by utilizing stannum-zinc-arsenic-contained complex iron ore

A technology of metallized pellets and composite iron ore, which is applied in the field of iron and steel metallurgy, can solve the problems of limited dosage and achieve the effects of reducing total energy consumption, accelerating reduction rate, and shortening reduction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

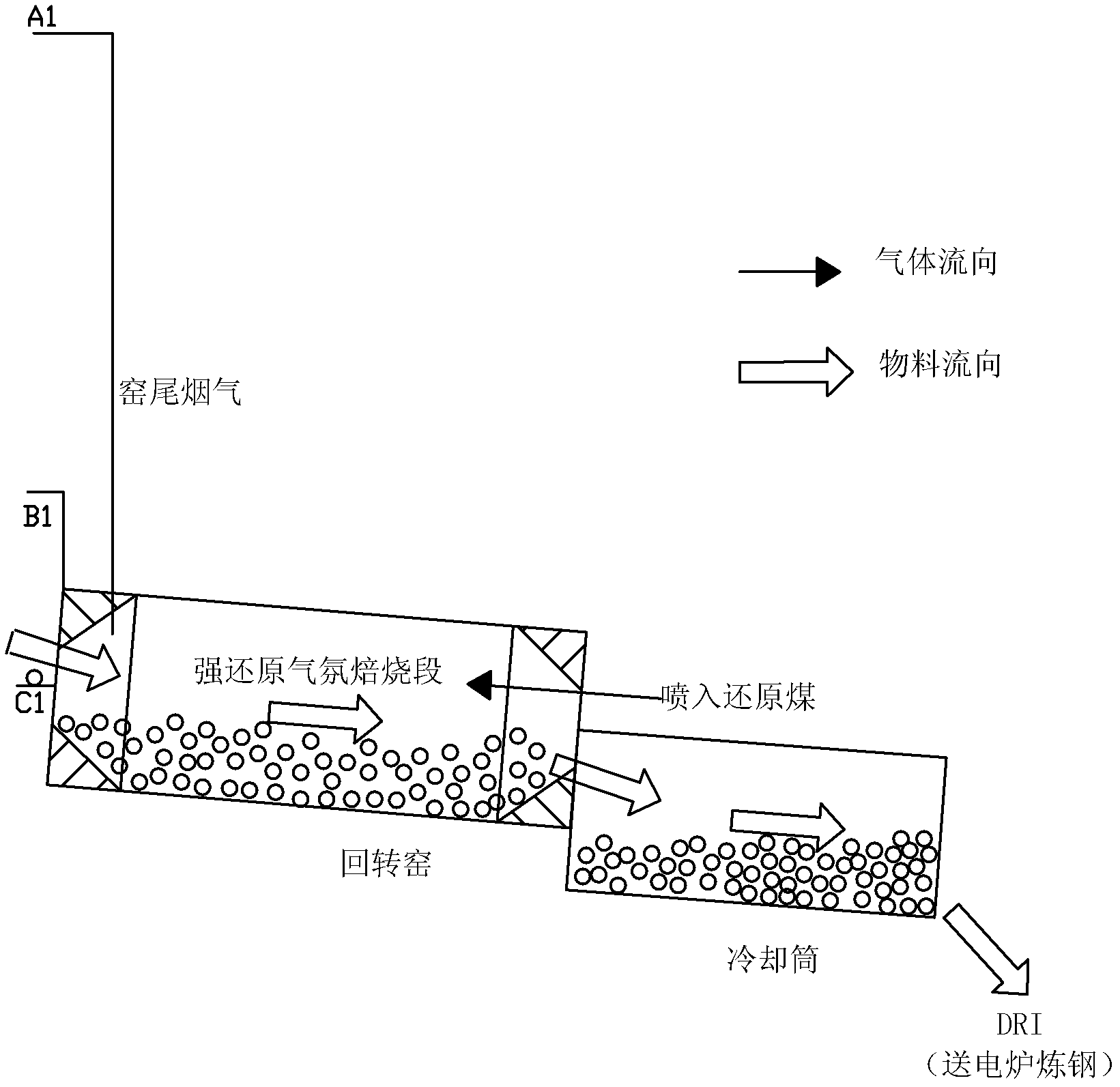

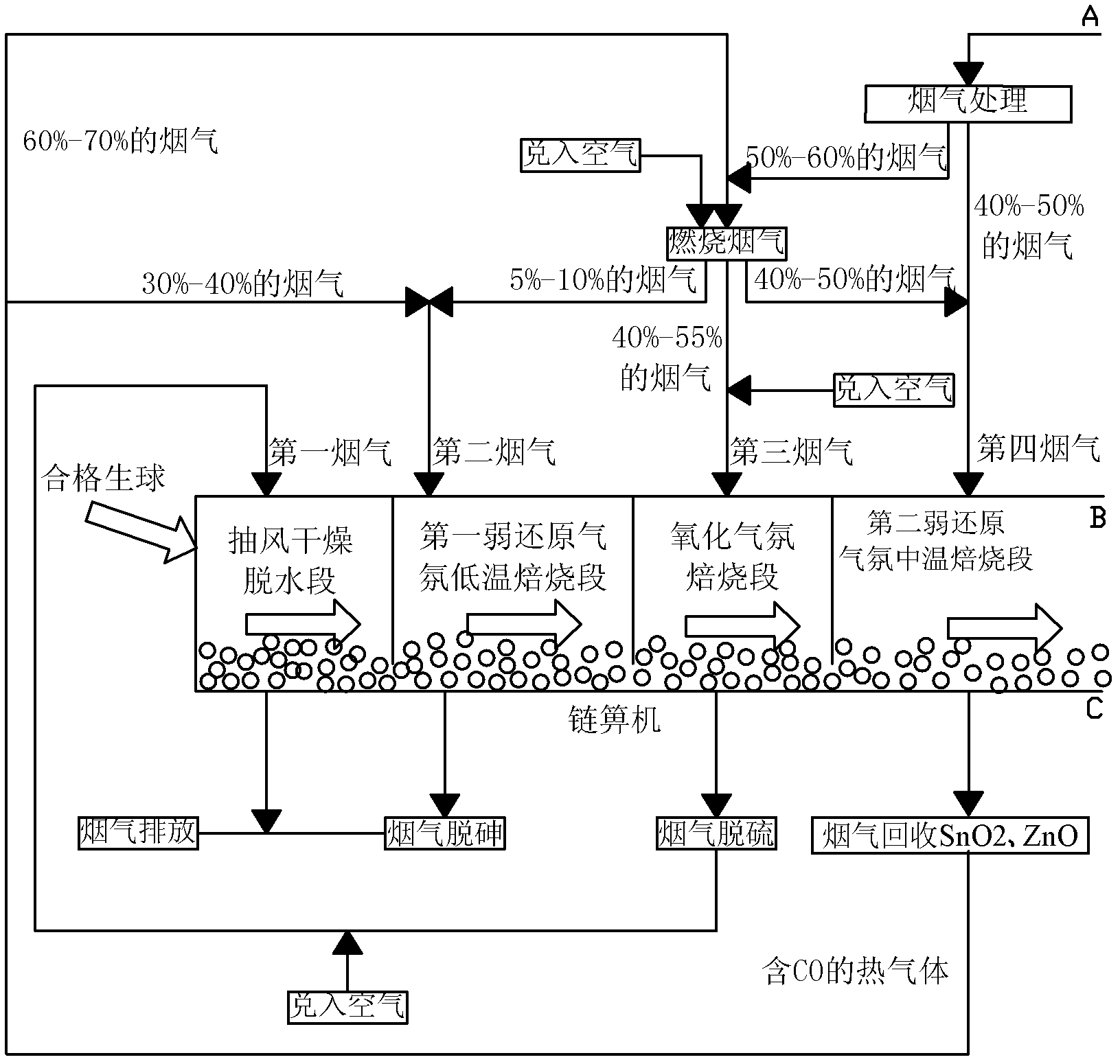

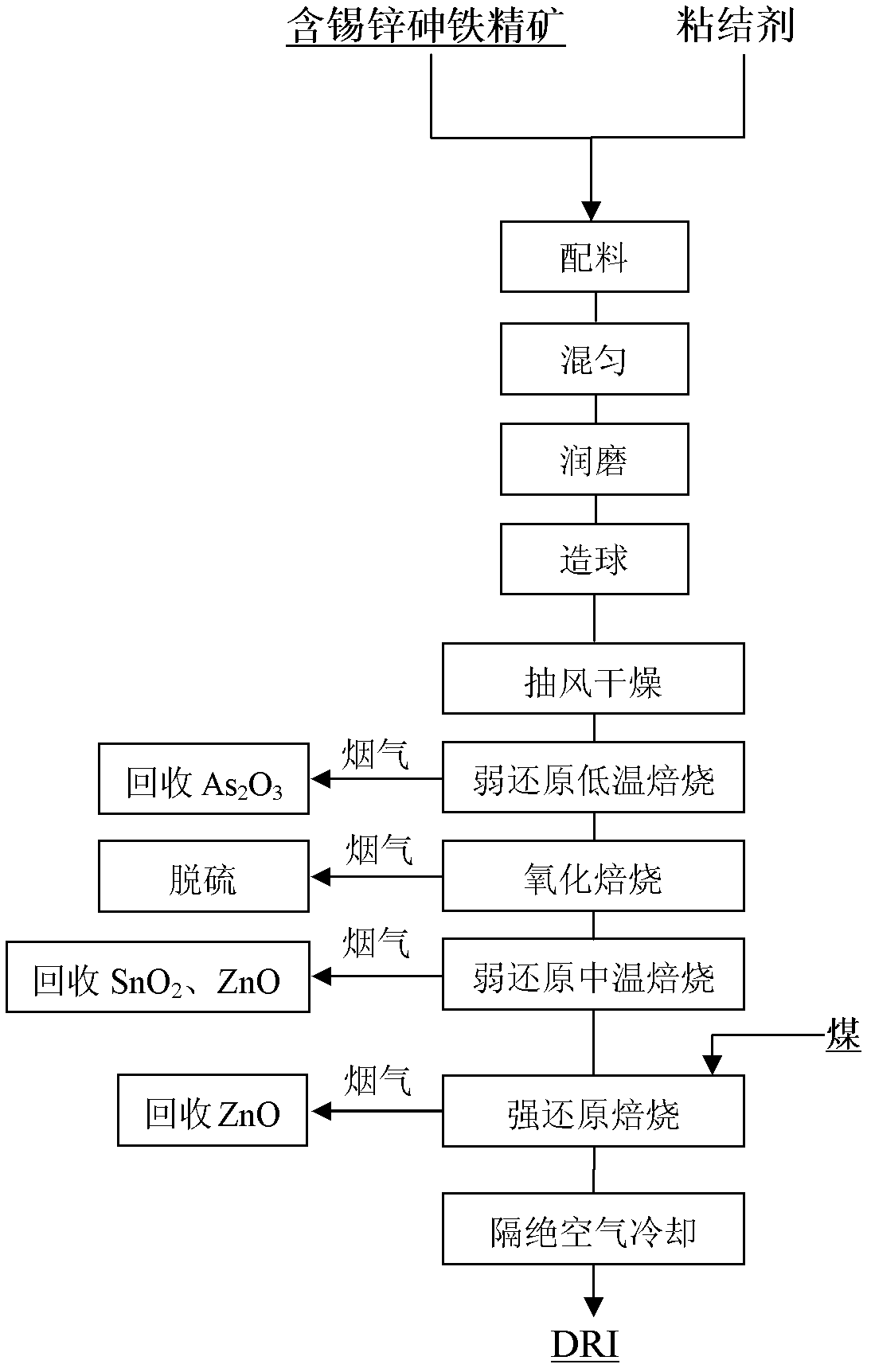

[0041] Embodiment 1: add coal sodium humate binder in the ratio of 0.5% of the mass percentage of the tin-containing zinc-arsenic iron ore concentrate, carry out batching, mix evenly, and obtain the mixture; Percentage is 5.0% water to carry out moistening grinding, and moistening time is 4min, obtains moistening abrasive; Moisturizing abrasive is used for pelletizing, and the mass percent content of controlling water in the pelletizing material is 8.5%, carries out pelletizing, and pelletizing time is 10min to produce green balls with a diameter of 10mm to 16mm; the raw balls are air-dried and dehydrated on the chain grate machine, the first low-temperature roasting in a weak reducing atmosphere to remove arsenic, the oxidizing atmosphere roasting for desulfurization, and the second high-temperature roasting in a weak reducing atmosphere to remove tin and zinc ;Drying system, the height of the green pellet layer on the chain grate machine is 220mm, the speed of the chain grate...

Embodiment 2

[0042] Embodiment 2: add coal sodium humate binder in the ratio of 1.0% of the mass percentage of the tin-containing zinc-arsenic iron concentrate, carry out batching, mix well, and obtain the mixture; Percentage is 7.0% water to carry out lubricating grinding, and lubricating grinding time is 7min, obtains lubricating abrasive; Moisturizing abrasive is used for pelletizing, and the mass percentage content of controlling water in the pelletizing material is 8.5%, carries out pelletizing, and pelletizing time is 10min to produce green balls with a diameter of 10mm to 16mm; the raw balls are air-dried and dehydrated on the chain grate machine, the first low-temperature roasting in a weak reducing atmosphere to remove arsenic, the oxidizing atmosphere roasting for desulfurization, and the second high-temperature roasting in a weak reducing atmosphere to remove tin and zinc ;Drying system, the height of the green pellet layer on the chain grate machine is 220mm, the machine speed o...

Embodiment 3

[0043] Embodiment 3: add coal sodium humate binder in the ratio of 1.0% of the mass percentage of the tin-containing zinc-arsenic iron concentrate, carry out batching, mix well, and obtain the mixture; Percentage is 8.0% water to carry out moistening grinding, and moistening time is 7min, obtains moistening abrasive; Moisturizing abrasive is used for pelletizing, and the mass percent content of controlling water in the pelletizing material is 8.5%, carries out pelletizing, and pelletizing time is 10min to produce green balls with a diameter of 10mm to 16mm; the raw balls are air-dried and dehydrated on the chain grate machine, the first low-temperature roasting in a weak reducing atmosphere to remove arsenic, the oxidizing atmosphere roasting for desulfurization, and the second high-temperature roasting in a weak reducing atmosphere to remove tin and zinc ;Drying system, the height of the green pellet layer on the chain grate machine is 220mm, the speed of the chain grate machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com