Growing method of magnesium fluoride barium single crystal

A technology of barium magnesium fluoride and growth method, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of difficult to realize single crystal industrial production, fluoride is easy to volatilize, easy to crack and other problems, and reach the crystal size And the shape is easy to control, not easy to crack, and the effect of stable temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

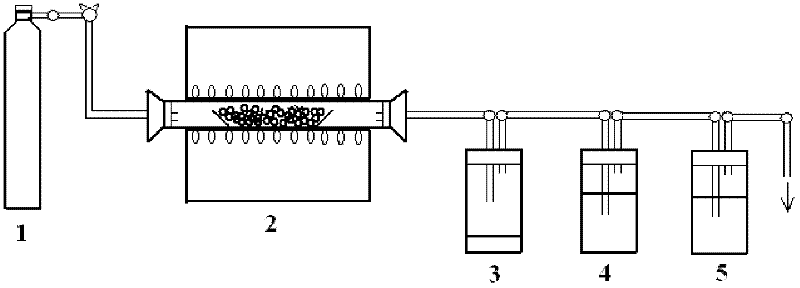

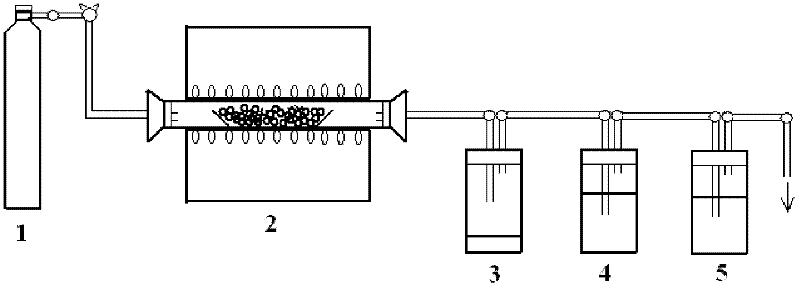

[0026] The high-purity raw material (99.9%) BaF 2 and MgF 2 Mix evenly according to the molar ratio of 1:1, and then put the mixed powder into figure 1 The device shown is fluoridated at 500-600°C for 5 hours;

[0027] The fluorinated powder and direction, cylindrical CaF 2 The single crystal is placed in a cylindrical platinum crucible with a wall thickness of 0.1mm, and then the crucible is airtight by gas welding;

[0028] Put the platinum crucible into the Bridgman single crystal furnace, and grow barium magnesium fluoride single crystal using the crucible drop method: the furnace temperature is controlled at 1000°C to melt the raw material and the top of the seed crystal, and the temperature gradient at the growth interface is maintained at 30°C / cm. At a rate of 1 mm / hour, transparent cylindrical BaMgF can be grown 4 complete crystals.

Embodiment 2

[0030] The high-purity raw material (99.9%) BaF 2 and MgF 2 Mix evenly according to the molar ratio of 1:1, and then put the mixed powder into figure 1 The device shown is fluorinated at 500-600°C for 6 hours;

[0031] The fluorinated powder and direction, rectangular columnar CaF 2 The single crystal is placed in a rectangular cylindrical platinum crucible with a wall thickness of 0.2mm, and then the crucible is airtight by gas welding;

[0032] Put the platinum crucible into the Bridgman single crystal furnace, and grow barium magnesium fluoride single crystal using the crucible drop method technology: the furnace temperature is controlled at 1450°C to melt the raw material and the top of the seed crystal, and the temperature gradient at the growth interface is maintained at 35°C / cm. At a rate of 2 mm / hour, transparent rectangular columnar BaMgF can be grown 4 complete crystals.

Embodiment 3

[0034] The high-purity raw material (99.9%) BaF 2 and MgF 2 Mix evenly according to the molar ratio of 1:1, and then put the mixed powder into figure 1 The device shown is fluoridated at 500-600°C for 10 hours;

[0035] The fluorinated powder and direction, cylindrical CaF 2 The single crystal is placed in a cylindrical platinum crucible with a wall thickness of 0.3mm, and then the crucible is airtight by gas welding;

[0036] Put the platinum crucible into the Bridgman single crystal furnace, and grow barium magnesium fluoride single crystal using the crucible drop method technology: the furnace temperature is controlled at 1350°C to melt the raw material and the top of the seed crystal, and the temperature gradient at the growth interface is maintained at 40°C / cm. At a rate of 3 mm / hour, transparent cylindrical BaMgF can be grown 4 complete crystals.

[0037] According to the growth method of the present invention, depending on the shape and size of the grown crystals,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com