Hierarchical porous structure carbon material for negative electrode of power lithium-ion battery and preparation method of hierarchical porous structure carbon material

A lithium-ion battery, hierarchical hole technology, applied in the direction of battery electrodes, structural parts, carbon preparation/purification, etc., can solve problems such as difficult to achieve large-scale preparation, complicated preparation process, and difficult to repeat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh phenolic resin 5g and copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) 19.757g (atomic ratio Cu: C=1: 4), and curing agent hexamethylenetetramine 0.7g, add 50ml absolute ethanol and stir to mix evenly, then 80 ℃ of water baths until absolute alcohol volatilizes completely, obtain red brown solid. Place it at 150° C. for 4 hours to make the thermoplastic phenolic resin fully cross-linked and solidified. Put the solidified product into a carbonization furnace, raise the temperature to 600° C. for 6 hours under the protection of nitrogen, and then cool it down to room temperature naturally to obtain a carbonized product. Add 30% H to the charred product 2 o 2 Aqueous solution, immerse the carbonized product, oxidize for 2 hours, add excess concentrated hydrochloric acid (36.8% ~ 38%), stir magnetically at room temperature for 12 hours, then suction filter and wash with deionized water until the filtrate is neutral, and dry at 80°C for 12 hours to obtain the target product ...

Embodiment 2

[0032] Operating condition is the same as embodiment 1, and difference is that copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) The mass was changed to 4.939g (atomic ratio Cu:C=1:20).

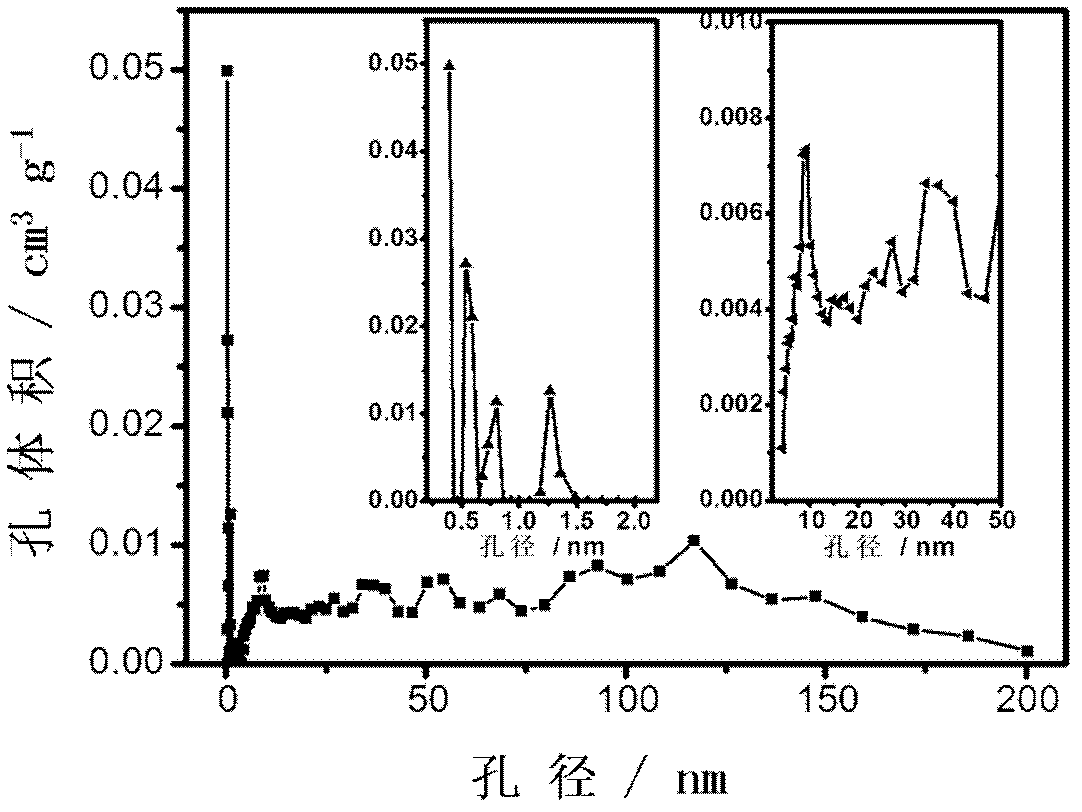

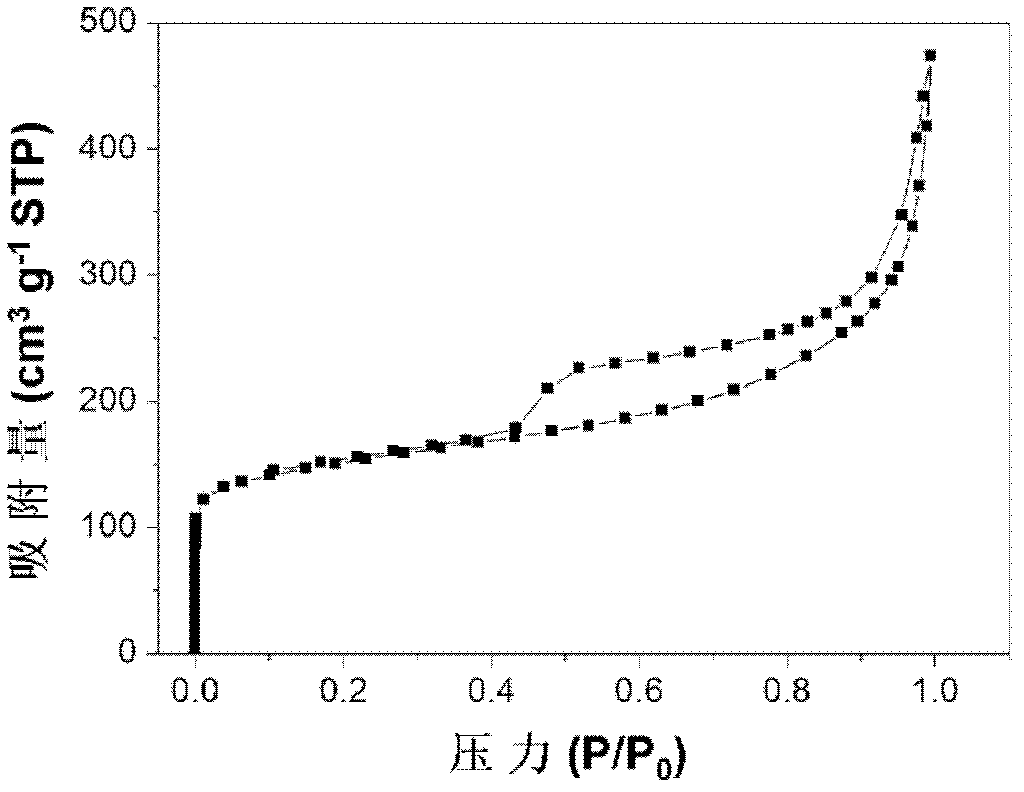

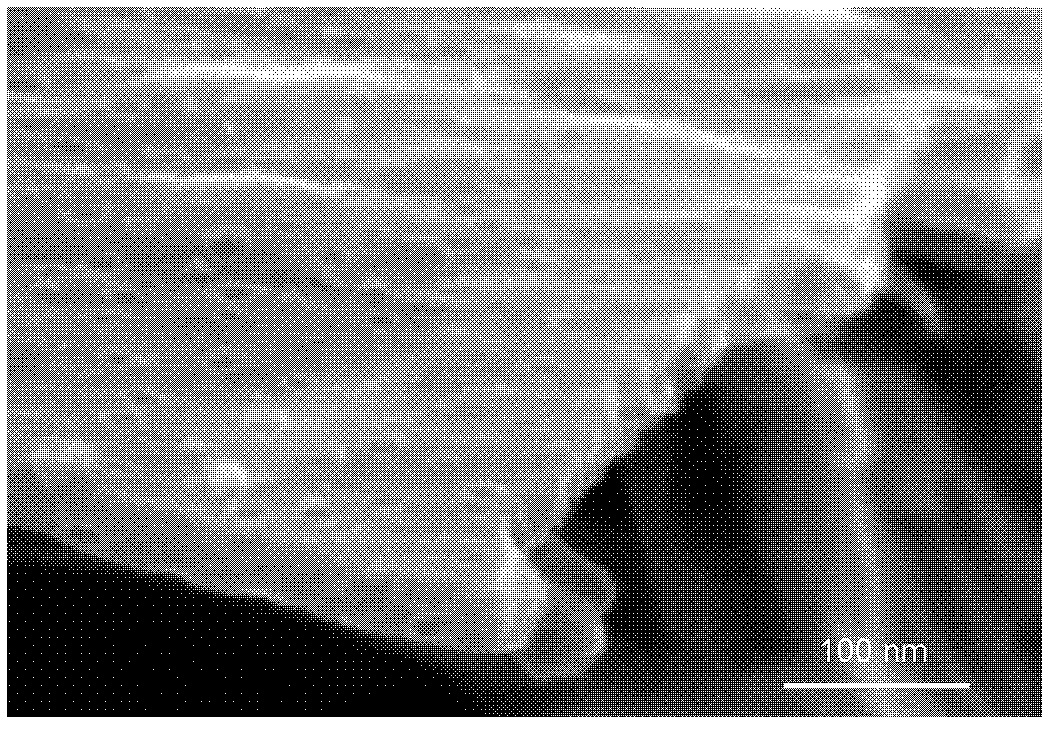

[0033] The width of the obtained carbon sheet is 5-20 μm, the thickness is about 40nm, and the specific surface area of the product is 336m 2 / g, the pore volume is 0.210cm 3 / g, the micropore diameter is 0.4-2nm, the mesopore diameter is 10-50nm, and the macropore diameter is 50-200nm. Compared with the product obtained in Example 1, the proportion of mesopores decreased. The electrochemical test was carried out by the same method as in Example 1, and the results showed that the reversible capacity reached 504 mAh / g at a current density of 20 mA / g, and after 50 cycles, the capacity could be maintained at 350 mAh / g. The reversible capacity is 205mAh / g at a current density of 1A / g.

Embodiment 3

[0035] The operating conditions are the same as in Example 1, except that the carbonization process is kept at 700° C. for 6 hours.

[0036] Through transmission electron microscope analysis, the obtained product carbon sheet has a width of 5-20μm, a thickness of about 30-40nm, and a specific surface area of 430m 2 / g, the micropore diameter is 0.4-2nm, the mesopore diameter is 10-40nm, and the macropore diameter is 50-150nm. The charging and discharging test was carried out in the same method as in Example 1, and the results showed that the reversible capacity reached 655 mAh / g at a current density of 20 mA / g, and the capacity remained at 480 mAh / g after 50 cycles. The reversible capacity is 438mAh / g at a current density of 1A / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com