Method for preparing molybdenum trioxide

A technology of molybdenum trioxide and sodium molybdate, applied in the direction of molybdenum oxide/molybdenum hydroxide, etc., can solve the problems of precipitating molybdenum element, difficult to generate solid precipitation, etc., and achieve the effects of improving decomposition rate, short production process and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

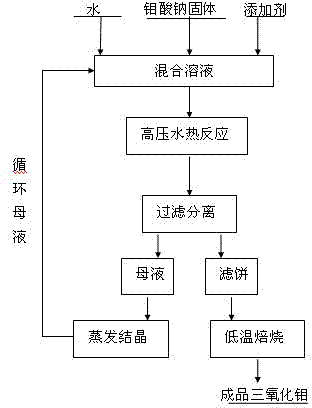

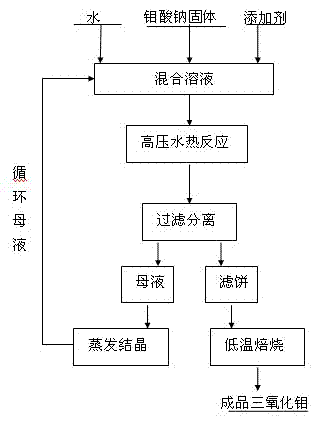

Image

Examples

Embodiment 1

[0024] Embodiment 1: preparation mass fraction is the sodium molybdate solution of 25%, is added in the solution with tartaric acid as additive, the dosage of additive is 1.2 times of sodium molybdate in stoichiometric molar ratio, and the mixed solution pH control is 7.3. Add the mixed solution into the autoclave and react at 110°C for 11 hours, and the decomposition rate of the sodium molybdate solution is 87%. The obtained slurry was separated by filtration, and the filter cake was washed with deionized water, then put into a roasting furnace, and roasted at a low temperature of 200°C for 4 hours to obtain the finished molybdenum trioxide with a purity of 99.8%. The mother liquor after slurry separation is evaporated and concentrated together with the washing liquid, and the crystallized mother liquor obtained is returned to the sodium molybdate solution preparation step.

Embodiment 2

[0025] Embodiment 2: preparation mass fraction is the sodium molybdate solution of 30%, is added in the solution with malic acid as additive, the dosage of additive is 1.4 times of sodium molybdate according to the stoichiometric molar ratio, and the pH control of mixed solution is 7.6. Add the mixed solution into the autoclave and react at 100°C for 12 hours, and the decomposition rate of the sodium molybdate solution is 91%. The obtained slurry was separated by filtration, and the filter cake was washed with deionized water, then put into a roasting furnace, and roasted at a low temperature of 300°C for 3 hours to obtain finished molybdenum trioxide with a purity of 99.9%. The mother liquor after slurry separation is evaporated and concentrated together with the washing liquid, and the crystallized mother liquor obtained is returned to the sodium molybdate solution preparation step.

Embodiment 3

[0026] Embodiment 3: preparation mass fraction is the sodium molybdate solution of 38%, is that additive is added in the solution with fumaric acid, the dosage of additive is 1.5 times of sodium molybdate by chemical equation metering molar ratio, mixed solution pH control is 7.8. Add the mixed solution into the autoclave and react at 140°C for 10 hours, and the decomposition rate of the sodium molybdate solution is 94%. The obtained slurry was separated by filtration, and the filter cake was washed with deionized water, then put into a roasting furnace, and roasted at a low temperature of 300°C for 3 hours to obtain finished molybdenum trioxide with a purity of 99.5%. The mother liquor after slurry separation is evaporated and concentrated together with the washing liquid, and the crystallized mother liquor obtained is returned to the sodium molybdate solution preparation step.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com