Method for preparing medical titanium material with high anti-cancer and antibacterial properties

A kind of titanium material, good technology, applied in the field of preparation of functionalized titanium material, can solve the problems of inability to achieve antibacterial effect, looseness, etc., achieve good anticancer and antibacterial performance, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

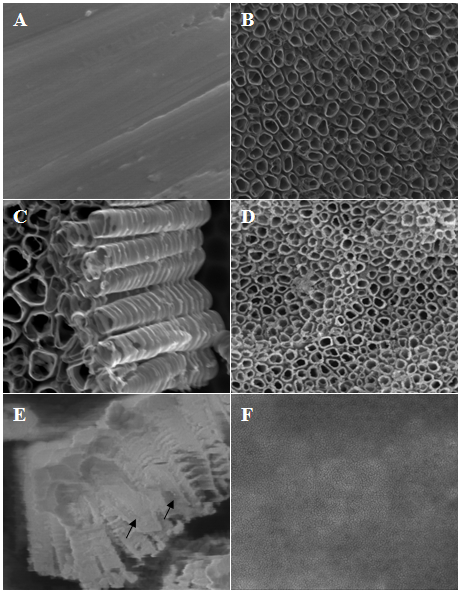

Image

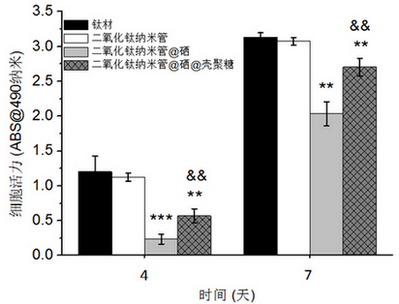

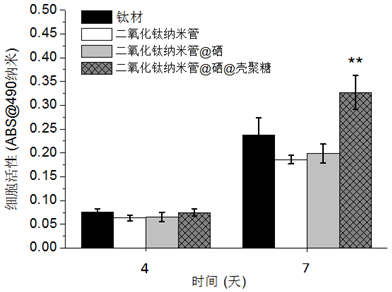

Examples

Embodiment 1

[0026] Embodiment 1. Preparation of medical titanium material with good anticancer and antibacterial properties

[0027] a. Pretreatment of titanium materials: ultrasonically clean the titanium materials with acetone, isopropanol and methanol for 20 minutes, then wash with deionized water for 3 times, dry at 40°C, and set aside;

[0028] b. Construction of titanium dioxide nanotube arrays: dissolving ammonium fluoride with a glycerol-water mixture with a volume ratio of 1:1 to make a solution with a concentration of 0.27mol / L as the electrolyte; use the titanium material obtained in step a as The anode, platinum as the cathode, is placed in the above-mentioned ammonium fluoride electrolyte, and the anodic oxidation reaction is carried out at a constant voltage of 30V for 30 minutes; the treated titanium material is washed 5 times with deionized water, dried at 40°C, and used for later use; the obtained titanium material is referred to as is "titanium dioxide nanotubes";

...

Embodiment 2

[0032] Embodiment 2. Preparation of medical titanium material with good anticancer and antibacterial properties

[0033] a. Pretreatment of titanium materials: ultrasonically clean the titanium materials with acetone, isopropanol and methanol for 20 minutes, then wash with deionized water for 3 times, dry at 40°C, and set aside;

[0034] b. Construction of titanium dioxide nanotube arrays: dissolving ammonium fluoride with a glycerol-water mixture with a volume ratio of 1:1 to make a solution with a concentration of 0.25mol / L as the electrolyte; use the titanium material obtained in step a as Anode, platinum as cathode, placed in the above-mentioned ammonium fluoride electrolyte, anodic oxidation reaction at a constant voltage of 30V for 45 minutes; the treated titanium material was washed 5 times with deionized water, dried at 40°C, and used for later use; the obtained titanium material is referred to as is "titanium dioxide nanotubes";

[0035]c. Loading of selenium nan...

Embodiment 3

[0037] Embodiment 3. Preparation of medical titanium material with good anticancer and antibacterial properties

[0038] a. Pretreatment of titanium materials: ultrasonically clean the titanium materials with acetone, isopropanol and methanol for 20 minutes, then wash with deionized water for 3 times, dry at 40°C, and set aside;

[0039] b. Construction of titanium dioxide nanotube arrays: dissolving ammonium fluoride with a glycerol-water mixture with a volume ratio of 1:1 to make a solution with a concentration of 0.30 mol / L as the electrolyte; use the titanium material obtained in step a as Anode, platinum as cathode, placed in the above-mentioned ammonium fluoride electrolyte, anodic oxidation reaction at a constant voltage of 30V for 60 minutes; the treated titanium material was washed 5 times with deionized water, dried at 40°C, and used for later use; the obtained titanium material is referred to as is "titanium dioxide nanotubes";

[0040] c. Loading of selenium n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com