Nitride passivation method for cavity surfaces of vacuum-cleaved high-power semiconductor laser

A semiconductor and laser technology, applied in the field of semiconductor laser coating, to avoid corrosion and contamination, reduce non-radiative recombination, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

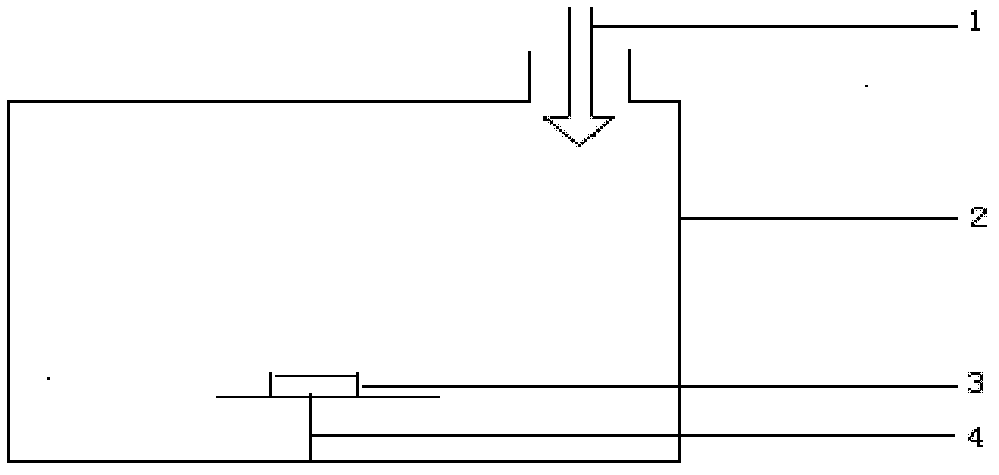

[0018] 1. Put the InGaAs / GaAs / AlGaAs / semiconductor laser with a lasing wavelength of 980nm on the cleavage table 4 in the new vacuum cleavage machine 2 with the ion source device, and feed high-purity nitrogen gas from the ion source 1, and the flow rate 35sccm, ion source energy 80ev, forming N in the cleavage chamber + When ions are cleaved in a pure nitrogen environment, the dangling bonds on the fresh cavity surface of the semiconductor laser are in the N + Reduced under the action of ions, put the cleaved semiconductor laser Bar 3 into the special coating fixture, and then quickly put it on the planetary turntable of the electron beam evaporation vacuum coating machine.

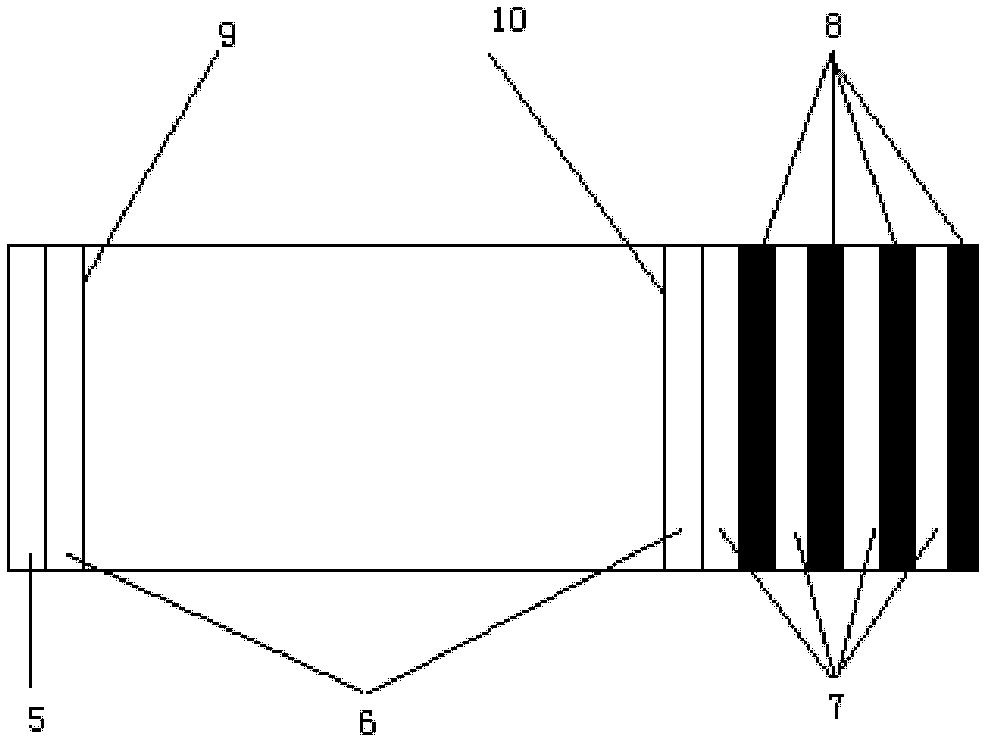

[0019] 2. Nitrogen ion deep plating passivation, pump the vacuum coating machine to high vacuum, turn on the nitrogen source, pass in the flow rate of 60sccm, bombard the cavity surface of the semiconductor laser with 100ev nitrogen ion beam, passivation temperature 250 ℃, passivation time 10min, in Rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com