Alpha-phase manganese dioxide nano-rod, and preparation method and application thereof

A technology of manganese dioxide and nanorods, applied in the direction of manganese oxide/manganese hydroxide, nanotechnology, electrical components, etc., can solve the problems of unsuitable for large-scale production, complicated process, harsh reaction conditions, etc., and achieve the improvement of fast charging The effects of discharge and service life, simple process, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

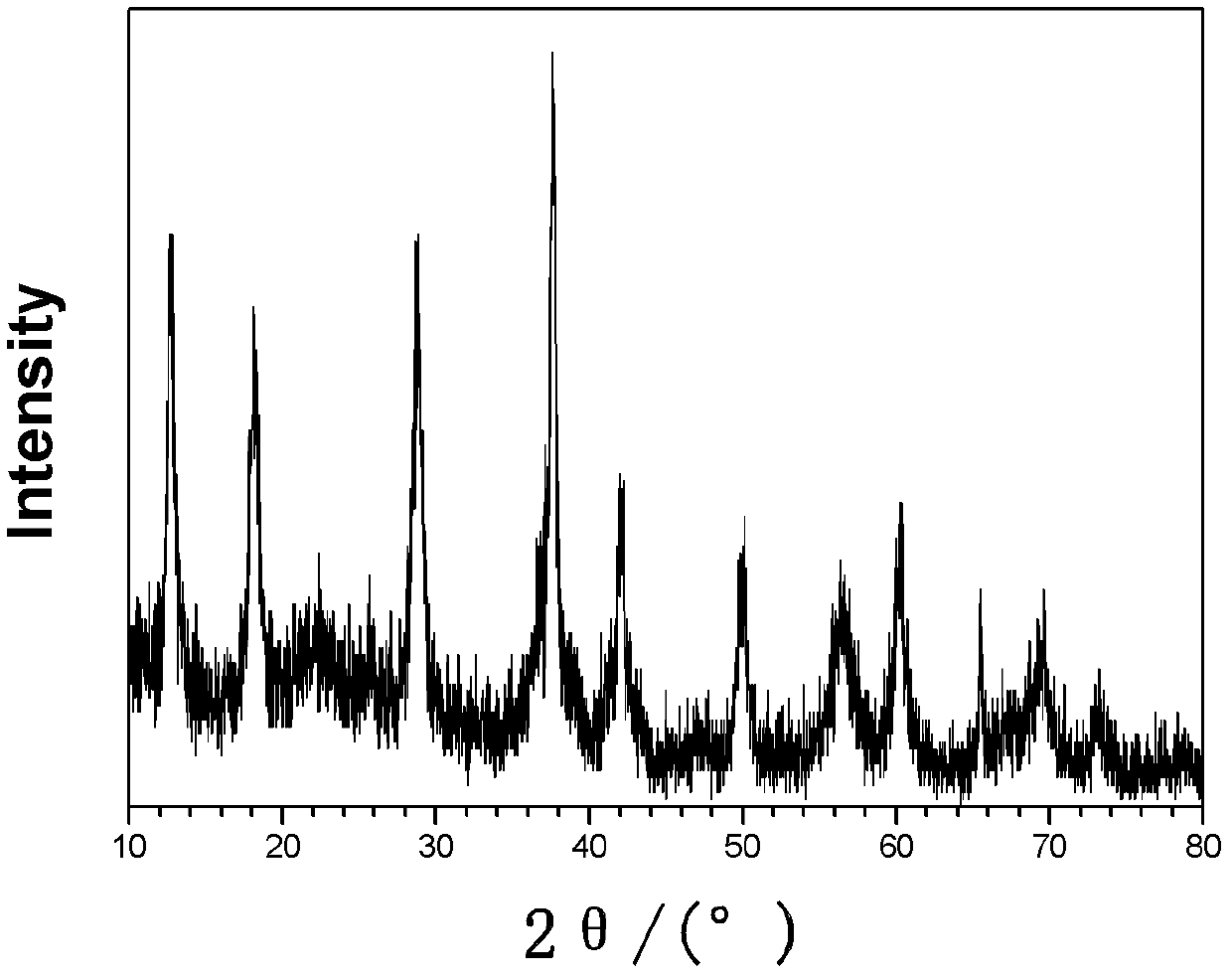

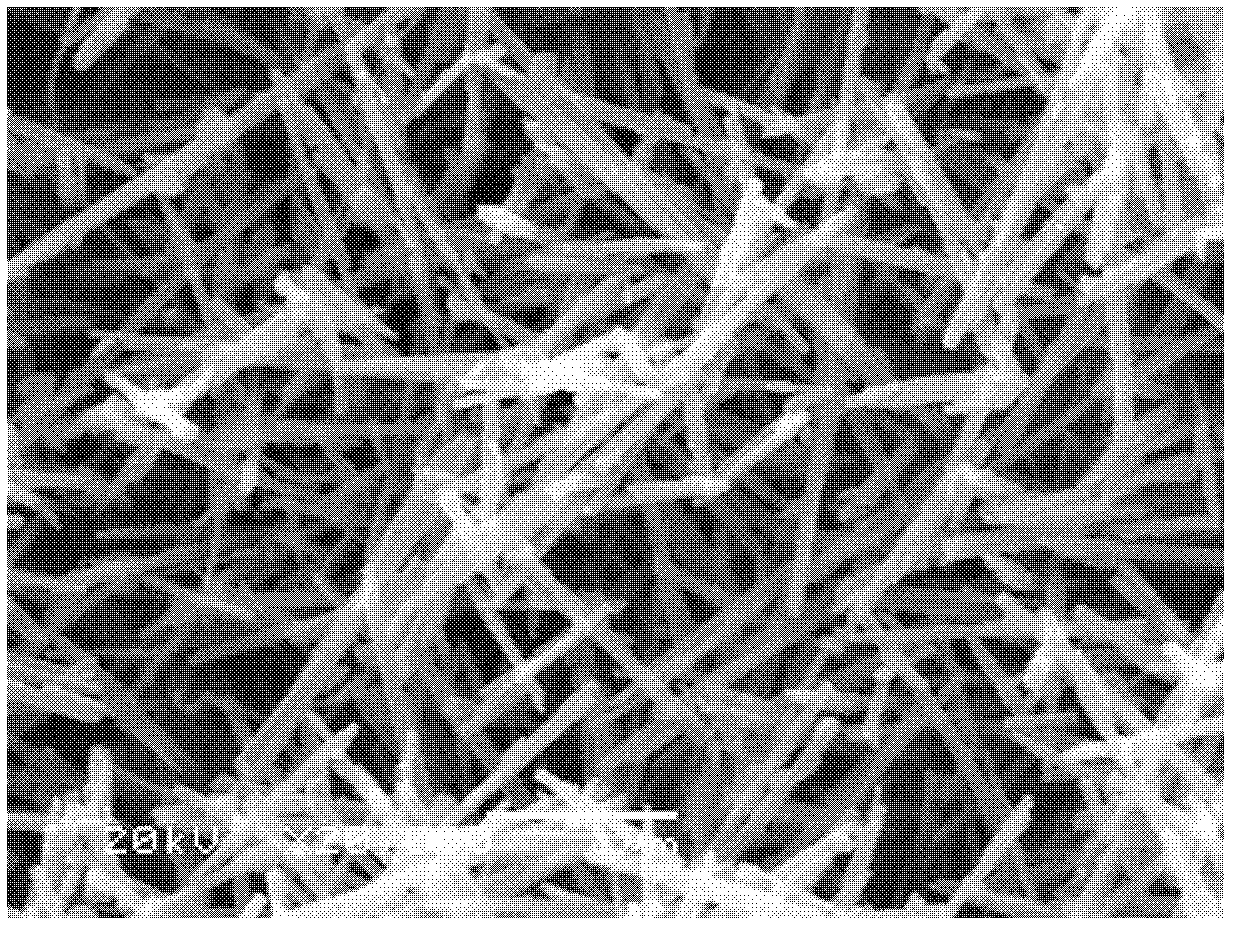

[0026] Weigh 0.632g potassium permanganate (4mmol) and 1.187g (6mmol) manganese chloride, dissolve them in 100mL deionized water respectively, slowly add potassium permanganate solution into the manganese chloride solution under vigorous stirring. Weigh 0.063g of potassium dichromate, dissolve it in 50mL of deionized water and add it to the reaction solution, then heat, boil and reflux for 2 hours, cool to room temperature, filter, wash with deionized water 3 times, and dry at 100°. From figure 1 , 2 You can see the α-phase manganese dioxide nanorods with a diameter of about 80nm and a length of about 1.5μm.

[0027] Application example of embodiment 1

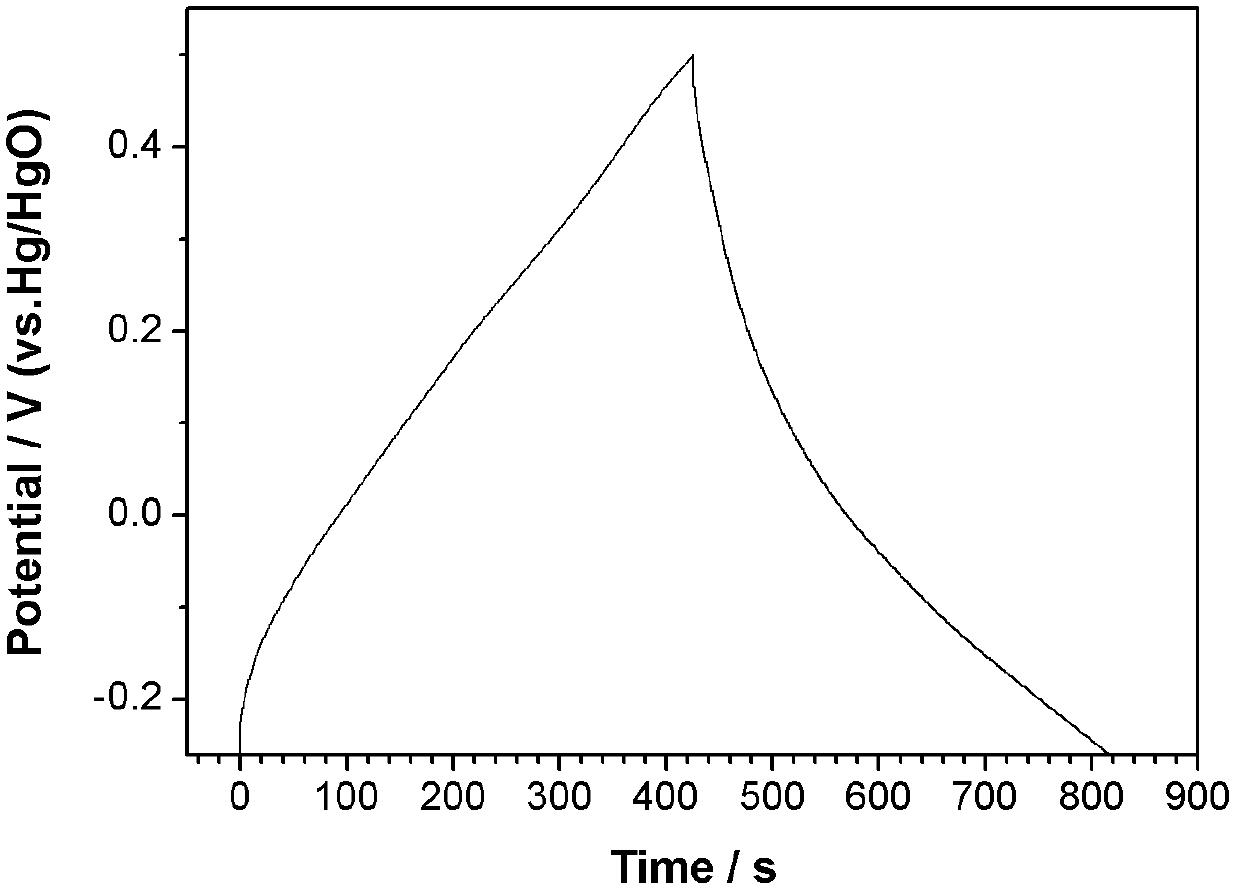

[0028] Mix the α-phase manganese dioxide nanorods prepared in Example 1, acetylene black, and polytetrafluoroethylene in a mass ratio of 7:2:1, add an appropriate amount of acetone to fully mix the three, make a slurry, and roll into thin sheets And cut 10 mg thin slices and press them on the nickel foam to make electrode s...

Embodiment 2

[0030] Weigh 0.632g (4mmol) of potassium permanganate and 1.014g (6mmol) of manganese sulfate, dissolve them in 100mL of deionized water, and slowly add the potassium permanganate solution into the manganese sulfate solution under vigorous stirring. Weigh 0.063g of potassium dichromate and dissolve it in 50mL of deionized water and add it to the reaction solution, then heat, boil and reflux for 2 hours, cool to room temperature, filter, wash with deionized water 3 times, and dry at 100°. From Figure 4 α-phase manganese dioxide nanorods with a diameter of about 100 nm and a length of about 1.5 μm can be seen.

[0031] Application example of embodiment 2

[0032] The α-phase manganese dioxide nanorod electrode was prepared according to the method described in the application example of Example 1 and its performance was tested. From Figure 5 , it can be measured that the capacitance value of the α-phase manganese dioxide nanorod electrode is 178F / g when the current is 0.5A / g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com