Sludge micro oxygen hydrolytic acidizing method

A technology of hydrolysis acidification and sewage treatment plant, which is applied in the field of sludge treatment and resource utilization, which can solve the problems of easy sedimentation of sludge and achieve good results, increase production and inhibit growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

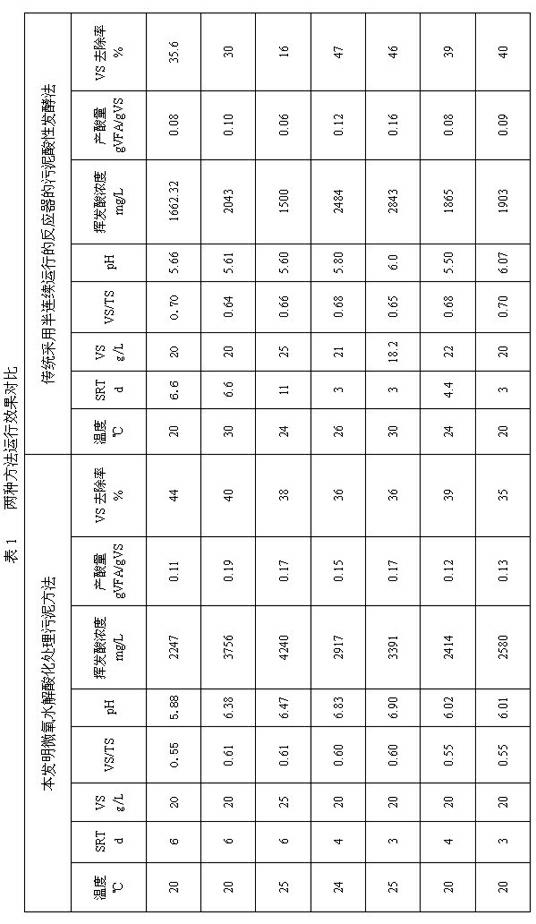

Image

Examples

Embodiment 1

[0029] The hydrolytic acidification reactor adopts a sequencing batch reactor, and the return sludge from the aeration tank of the sewage treatment plant is inoculated into the sequencing batch reactor, and the amount of inoculated sludge is 60% of the reactor volume. After inoculation, add carbohydrate organic waste water as the medium, carry out mechanical stirring and air stirring in the sequencing batch reactor at room temperature, both at the same time, stirring once every 60 minutes, each stirring time is 5 minutes, and the mechanical stirring intensity is 10W / m 3 , the volume of air stirred by air is 0.06m 3 / m 3 Pool capacity min, to maintain the micro-aerobic condition where the DO in the reactor is 0.4mg / L. The cultivation and acclimatization of acid-producing bacteria generally takes 7 to 14 days. No sludge is discharged during the cultivation process. The supernatant is discharged after the stirring is stopped and allowed to settle for 1 hour every day, and at t...

Embodiment 2

[0033] The stirring interval time is 60min, the stirring time is 7min, the SRT is 4d, and the others are the same as in Example 1.

Embodiment 3

[0035] The stirring interval is 40 minutes, the stirring time is 5 minutes, the VS entering the sludge is 20g / L, VS / TS=0.55, and the SRT is 3d. The pH value in the reactor is naturally maintained by the acid-producing bacteria in the reactor and the volatile acid and alkalinity produced by it. At 6.0, others are the same as in Example 1.

[0036] The volatile acid concentration in the mud-water mixture after hydrolysis and acidification treatment was 2693mg / L, the acid production of sludge was 0.14gVFA / gVS, and the removal rate of VS was 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com