Environment-friendly low-temperature sintered high-epsilon microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and low-temperature sintering, applied in the field of microwave dielectric ceramics, can solve the problems of Pb being highly toxic, unable to meet the needs of environmental protection, and difficult to make casting slurry, etc., and achieve the effect of simple process and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

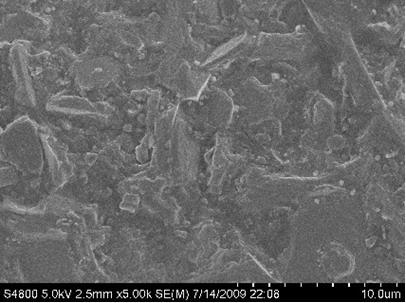

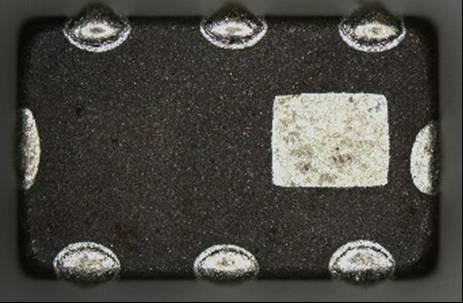

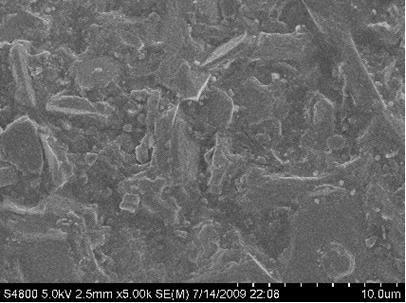

Image

Examples

Embodiment 1

[0027] ①The analysis of pure lithium carbonate (Li 2 CO 3 ), niobium pentoxide (Nb 2 o 5 ), titanium dioxide (TiO 2 ) at 130 ℃ Press LiNb after 24 hours under-bake 0.6 Ti 0.5 o 3 (i.e. m=0.1, n=0.1) Weigh by chemical formula, mix the weighed powder in a horizontal ball mill for 24 hours according to the weight ratio of powder: industrial alcohol: zirconia balls: 1:1.7:5, After the uniformly mixed slurry was dried at 80°C, it was pre-fired in the atmosphere at 850°C for 4 hours to synthesize LiNb 0.6 Ti 0.5 o 3 , pre-fired LiNb 0.6 Ti 0.5 o 3 Sieve through a 40-mesh sieve.

[0028] ② will analyze pure zinc oxide (ZnO), niobium pentoxide (Nb 2 o 5 ) by ZnNb after baking at 130°C for 24 hours 2 o 6 Weigh by chemical formula, mix the weighed powder according to the weight ratio of powder: industrial alcohol: zirconia ball: 1:1.5:5, mix in a horizontal ball mill for 24 hours, and dry the evenly mixed slurry at 80°C After that, it was pre-fired in the atmosphere at...

Embodiment 2

[0035] ① According to the composition of Li 1.095 Nb 0.375 Ti 0.8 o 3 (m=0.1, n=0.175) through embodiment 1 step 1. synthetic Li 1.095 Nb 0.375 Ti 0.8 o 3 Binder.

[0036] ②According to the composition of ZnNb 2 o 6 Through embodiment 1 step 2. synthetic ZnNb 2 o 6 .

[0037] ③The synthesized Li 1.095 Nb 0.375 Ti 0.8 o 3 and ZnNb 2 o 6 and MnCO 3 , CuO, Bi 2 o 3 , Li 2 CO 3 Press Li 1.095 Nb 0.375 Ti 0.8 o 3 +awt%ZnNb 2 o 6 +bwt%MnCO 3 +cwt%CuO+dwt%Bi 2 o 3 +ewt%Li 2 CO 3 (See Table 2 for the specific formula.) After step ③ of Example 1, it is pressed into a round block, sintered in an air atmosphere at 900°C, and kept warm for 3 hours to obtain the ceramic material of the present invention.

[0038] The performance measurement method is the same as in Example 1, and the test results are shown in Table 2 (the test frequency is 3 GHz).

[0039] Table 2

[0040] serial number m n a b c d e Density (g / cm 3 ) ε r Qf(GHz)...

Embodiment 3

[0042] ① According to the composition of Li 1.025 Nb 0.675 Ti 0.4 o 3 (m=0.1, n=0.075) through embodiment 1 step 1. synthetic Li 1.025 Nb 0.675 Ti 0.4 o 3 .

[0043] ②The synthesized Li 1.025 Nb 0.675 Ti 0.4 o 3 and MnCO 3 , CuO, Bi 2 o 3 , Li 2 CO 3 Press Li 1.025 Nb 0.675 Ti 0.4 o 3 +bwt%MnCO 3 +cwt%CuO+dwt%Bi 2 o 3 +ewt%Li 2 CO 3 (See Table 3 for the specific formula.) After step ③ of Example 1, it is pressed into a round block, sintered in an air atmosphere at 900°C, and kept warm for 3 hours to obtain the ceramic material of the present invention.

[0044] The performance measurement method is the same as in Example 1, and the test results are shown in Table 3 (the test frequency is 3 GHz).

[0045] table 3

[0046] serial number m n a b c d e Density (g / cm 3 ) ε r Qf(GHz) τ f (ppm / °C) 8 0.1 0.075 0 1.5 1.5 0 2 4.15 70.15 3965 7 9 0.1 0.075 0 1.5 1 0.25 2 4.14 70.63 3840 8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com