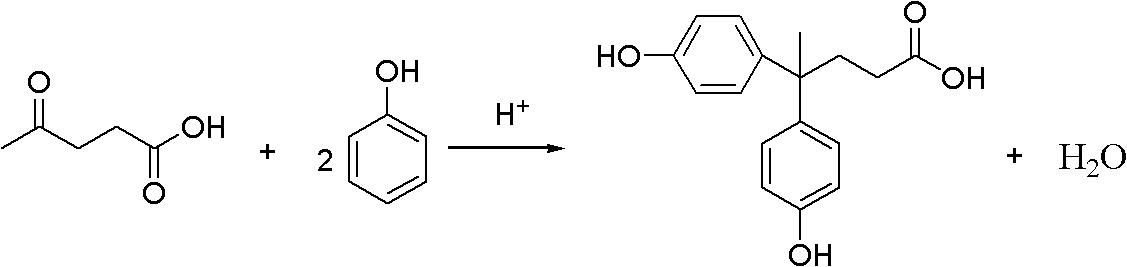

Method for preparing diphenolic acid in ionic liquid

An ionic liquid, bisphenolic acid technology, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of difficult recovery of catalysts, easy corrosion of equipment, long process flow, etc. Convenient operation and the effect of accelerating mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

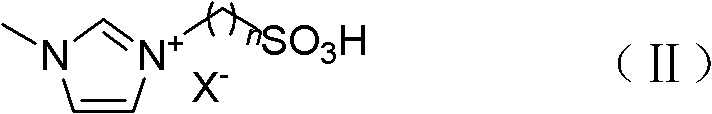

[0060] 1. Nucleophilic addition reaction

[0061] Add 208.3g (1.0mol) hydrogen sulfate 1-ethyl-3-methylimidazole ([Emim]HSO 4 ) And 94.1g (1.0mol) phenol, stir and mix; then add 29.0g (0.25mol) levulinic acid and 1.9g (0.015mol) promoter sodium sulfite into the reaction kettle, stir and mix to obtain a mixture; Slowly heat the reaction kettle to raise the temperature of the reaction kettle to 40°C, and make the mixture undergo a nucleophilic addition reaction under stirring to obtain a reaction mixture; wherein the molar ratio of levulinic acid, phenol and ionic liquid in the mixture is 1: 4:4, the molar ratio of levulinic acid to the co-catalyst is 1:0.06, the reaction temperature is controlled to 40°C, and the reaction time is 20 hours;

[0062] 2. Separate the reaction mixture

[0063] Add 1.0L of cooled deionized water (4°C) to the above reaction mixture, stir and mix thoroughly for 5 minutes, then stand and separate to obtain the upper organic phase and the lower aqueous phase;...

Embodiment 2

[0072] In addition to the nucleophilic addition reaction step, 368.4g (1.0mol) trifluoromethanesulfonate 1-methyl-3-butanesulfonate imidazole ionic liquid ([BSmim]CF 3 SO 3 ) And 94.1g (1.0mol) phenol, stir and mix; then add 29.0g (0.25mol) levulinic acid and 1.9g (0.015mol) promoter sodium sulfite into the reaction kettle, stir and mix to obtain a mixture; Slowly heat the reaction kettle to raise the temperature of the reaction kettle to 60°C, and make the mixture undergo a nucleophilic addition reaction under stirring to obtain a reaction mixture; wherein the molar ratio of levulinic acid, phenol and ionic liquid in the mixture is 1: 4:4, the molar ratio of levulinic acid to the co-catalyst is 1:0.06, the reaction temperature is controlled to 60°C, and the reaction time is 20 hours. The rest are the same as in Example 1, and the yield of bisphenolic acid is 92.5%;

[0073] Bisphenolic 1 HNMR nuclear magnetic characterization data are: 1 HNMR (DMSO, 400MHz, TMS) δ 1.45 (s, 3H, CH...

Embodiment 3

[0075] In addition to the nucleophilic addition reaction step, 316.3g (1.0mol) hydrogen sulfate 1-methyl-3-butanesulfonyl imidazole ionic liquid ([BSmim]HSO 4 ) And 141.2g (1.5mol) phenol, stir and mix; then add 29.0g (0.25mol) levulinic acid and 0.8g (0.005mol) promoter sodium thiosulfate into the reaction kettle, stir and mix well to prepare Obtain a mixture; slowly heat the reactor to raise the temperature of the reactor to 50°C, and make the mixture undergo a nucleophilic addition reaction under stirring to obtain a reaction mixture; wherein, the molar ratio of levulinic acid, phenol and ionic liquid in the mixture It is 1:6:4, the molar ratio of levulinic acid to co-catalyst is 1:0.02, the reaction temperature is controlled to 50°C, and the reaction time is 15 hours. The rest are the same as in Example 1. The yield of bisphenolic acid is 83.2%;

[0076] Bisphenolic 1 HNMR nuclear magnetic characterization data are: 1 HNMR (DMSO, 400MHz, TMS) δ 1.45 (s, 3H, CH 3 ), 1.89~1.93(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com