Preparation method of cupric glycinate complex compound

A technology of copper glycinate and complexes, which is applied in the field of preparation of copper glycinate complexes, can solve the problems of soil water quality environmental pollution, death, hemolysis, etc., and achieve the effects of avoiding environmental pollution, good solubility, and reducing waste liquid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

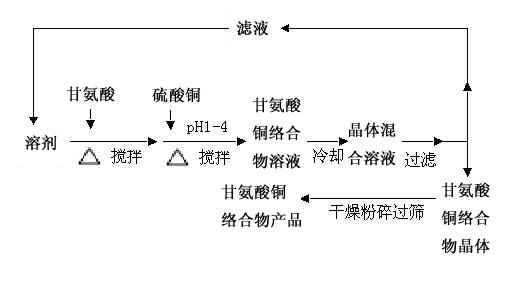

Method used

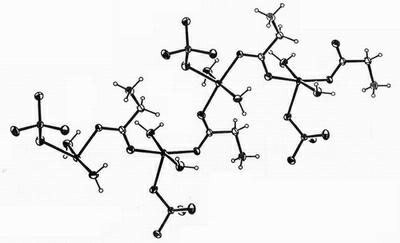

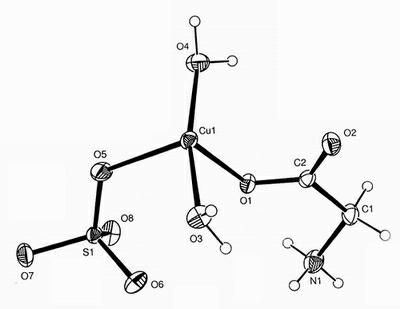

Image

Examples

Embodiment 1

[0039] Example 1: The reaction molar ratio of glycine and copper sulfate is 1:1, add 100g of glycine to 150ml aqueous solution and raise the temperature to 45°C, add 333g of copper sulfate pentahydrate under stirring, control the pH=1.0, heat up to 80°C, and react 1.5 hour, after the complexation reaction is completed, the glycine copper complex solution is generated, and the glycine copper complex solution is cooled to normal temperature with stirring, and the glycine copper complex crystals are separated out to form a crystal mixed solution, and the above crystal mixed solution is filtered to make it "Solid-liquid separation", the filtrate is refluxed and reused, the filter cake (i.e. crystal) is dried, pulverized, and sieved to 20 meshes to produce 289.7g of glycine copper complex product glycine sulfate dihydrate copper (II), with a yield of 80.69 %.

Embodiment 2

[0040] Example 2: The reaction molar ratio of glycine and copper sulfate is 1:1.3, add 100g of glycine to 200ml aqueous solution and heat up to 50°C, stir, add 433g of copper sulfate pentahydrate, control pH=1.8, heat up to 85°C, and react 2 hour, after the complexation reaction is completed, the glycine copper complex solution is generated, and the glycine copper complex solution is cooled to normal temperature with stirring, and the glycine copper complex crystals are separated out to form a crystal mixed solution, and the above crystal mixed solution is filtered to make it "Solid-liquid separation", the filtrate is refluxed and reused, the filter cake (i.e. crystal) is dried, pulverized, and sieved to 30 meshes to produce 298.5g of glycine copper complex product glycine sulfate dihydrate copper (II), with a yield of 83.15 %.

Embodiment 3

[0041] Example 3: The reaction molar ratio of glycine and copper sulfate is 1.25:1, add 100 g of glycine to 150 ml of aqueous solution and raise the temperature to 55 ° C, stir, add 266 g of copper sulfate pentahydrate, control pH = 4, heat up to 90 ° C, and react 2.5 After the completion of the complexation reaction, a glycine copper complex solution is generated, and the glycine copper complex solution is cooled to normal temperature with stirring, and the glycine copper complex crystals are separated out to form a crystal mixed solution. Filter the above crystal mixed solution to make it "solid-liquid separation", the filtrate is refluxed and reused, the filter cake (i.e. the crystal) is dried, crushed, and sieved to 30 meshes to make the copper glycine complex product copper glycine sulfate dihydrate (II) 293.3g, yield 81.72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com