Preparation method and application of physiologically active notoginseng polysaccharide

A technology of notoginseng polysaccharide and physiological activity, which is applied in the field of natural medicine preparation, can solve the problems of not being purified and refined, affecting the quality of end products, and low purity of notoginseng polysaccharide, achieving significant physiological activity, easy industrial production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

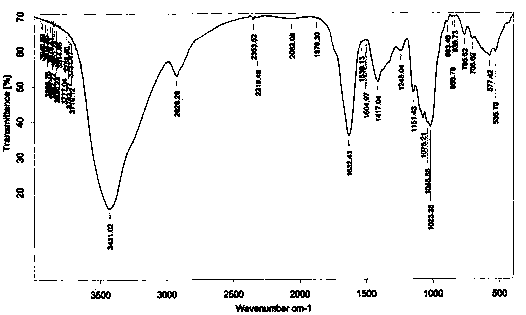

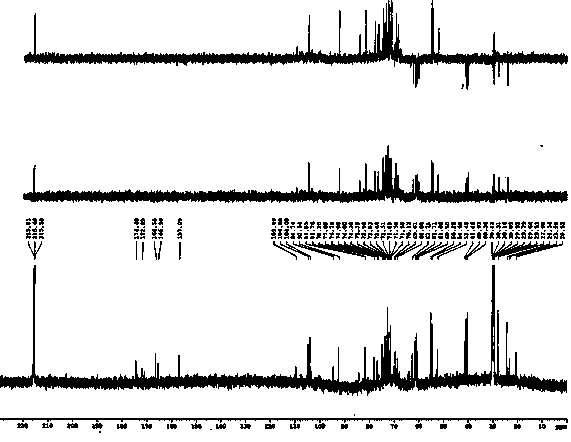

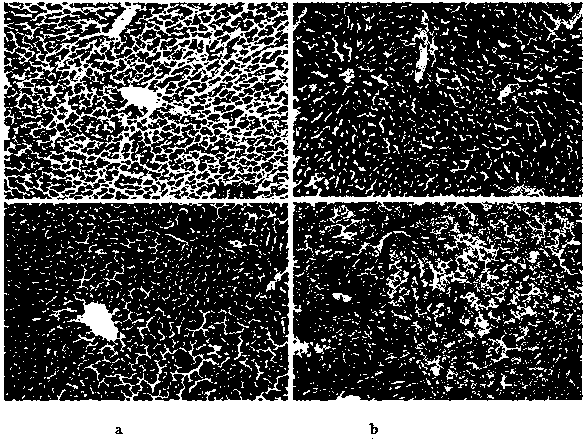

Embodiment 1

[0071] Take 1 kg of Panax notoginseng main root, crush it, heat and extract it with 8 kg of water at 80° C., extract three times, combine the extracts, cool, and centrifuge at 9000 rm for 10 minutes. The centrifuged supernatant was purified with pretreated polystyrene macroporous adsorption resin OU-291, the column flow rate was 0.3BV / h, washed with 1.0BV purified water equivalent to the column volume, and the flow rate was 1.5BV / h. h, combined eluents. The eluate passes through an aromatic polyamide flat ultrafiltration membrane with a molecular weight cut-off of 300 and a relative density of the retentate of 1.02. Add 3 times the amount of ethanol to the retentate, let it stand for 1 hour, precipitate, and centrifuge. The precipitate was dissolved in water until the relative density of the retentate was 1.02, and spray-dried to obtain 45 g of Panax notoginseng polysaccharide. The prepared Panax notoginseng polysaccharide was processed by high-temperature ashing method, and...

Embodiment 2

[0073] Take 1 kg of Panax notoginseng, crush it, extract it three times with ethanol with a mass concentration of 70%, heat the residue to 90°C for three times, and extract three times with 6 kg of water each time, combine the extracts, cool, and centrifuge at a speed of 5000rm, centrifuge for 15 minutes, centrifuge The final supernatant was purified with pretreated cation exchange resin, the column flow rate was 1.0BV / h, washed with 2.0BV purified water equivalent to the volume of the chromatography column, the flow rate was 0.5BV / h, combined eluents, and granulated 40 g of activated carbon was stirred at 60°C for 30 minutes for decolorization, and the clear liquid was obtained by filtration. The clear liquid passed through a cellulose acetate ultrafiltration membrane with a molecular weight cut-off of 500, and the relative density of the retained liquid was 1.03. Add 5 times the amount of ethanol to the retentate, let it stand for 1 hour, precipitate, and centrifuge. The pre...

Embodiment 3

[0075] Take 1kg of Panax notoginseng bars, crush them, heat and extract with 7kg of water at 100°C, extract three times, combine the extracts, cool, and centrifuge at 10000rm for 10 minutes. The centrifuged supernatant was purified with pretreated polystyrene macroporous adsorption resin LAR-714, the column flow rate was 1.0BV / h, washed with 2.0BV purified water equivalent to the column volume, and the flow rate was 0.8BV / h. h, combined eluents. The eluate passes through an aromatic polyamide flat ultrafiltration membrane with a molecular weight cut-off of 400 and a relative density of the retentate of 1.03. Add 3 times the amount of ethanol to the retentate, let it stand for 1 hour, precipitate, and centrifuge. The precipitate was dissolved in water until the relative density of the retentate was 1.02, and spray-dried to obtain 42 g of Panax notoginseng polysaccharide. The prepared Panax notoginseng polysaccharide was processed by high-temperature ashing method and detected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com