Urea tube and production process thereof

A production process and technology for urea pipes, which are applied in the field of urea pipes, can solve problems such as high cost and complex formula, and achieve the effects of ensuring safety, good aging resistance and excellent lubricating oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

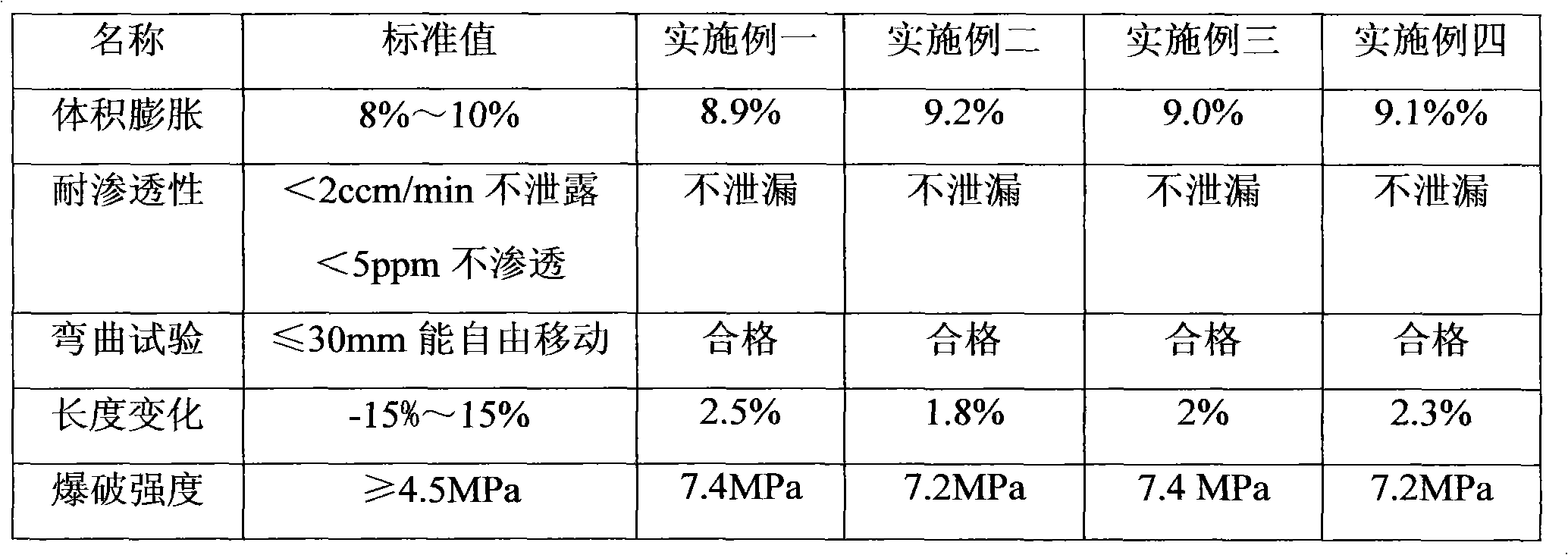

Examples

Embodiment 1

[0037] The compound is made from raw materials with the following weight components:

[0038] EPDM 48%,

[0040] Stearic acid 3%,

[0041] Phenolic resin 0.5%,

[0042] Silica 10%,

[0043] Anti-aging agent 0.2%,

[0044] Silica-alumina carbon black 15%,

[0046] Polyethylene Wax 8%,

[0047] Vulcanizing agent S 0.15%,

[0048] Accelerator DM 0.15%,

[0049] Accelerator TMTD 0.3%,

[0050] Accelerator DTDM 1.8%,

[0051] Accelerator PZ 0.3%,

[0052] Anti-scorch agent 0.1%.

[0053] 1) Put EPDM rubber, zinc oxide, stearic acid, phenolic resin and anti-aging agent into pressurized banburying, then add white carbon black, silicon aluminum carbon black, calcium carbonate and polyethylene wax into banburying, the pressure It is 0.5±0.05MPa. During mixing, when the temperature rises to 80°C, lift the top bolt once, when the temperature rises to 90°C, lift the top bolt once, and when the temperature rises to 110°...

Embodiment 2

[0057] The compound is made from raw materials with the following weight components:

[0058] EPDM 52%,

[0060] Stearic Acid 2.8%,

[0061] Phenolic resin 0.6%,

[0062] Silica 10%,

[0063] Anti-aging agent 0.3%,

[0064] Silica-alumina carbon black 15%,

[0066] Polyethylene wax 6%,

[0067] Vulcanizing agent S 0.25%,

[0068] Accelerator DM 0.25%,

[0069] Accelerator TMTD 0.3%,

[0070] Accelerator DTDM 1.5%,

[0071] Accelerator PZ 0.4%,

[0072] Anti-scorch agent 0.1%.

[0073] 1) Put EPDM rubber, zinc oxide, stearic acid, phenolic resin and anti-aging agent into pressurized banburying, then add white carbon black, silicon aluminum carbon black, calcium carbonate and polyethylene wax into banburying, the pressure It is 0.5±0.05MPa. During mixing, when the temperature rises to 80°C, lift the top bolt once, when the temperature rises to 90°C, lift the top bolt once, and when the temperature rises to 110°C...

Embodiment 3

[0077] The compound is made from raw materials with the following weight components:

[0078] EPDM 45%,

[0080] Stearic acid 3%,

[0081] Phenolic resin 0.5%,

[0082] Silica 15%,

[0083] Anti-aging agent 0.5%,

[0084] Silico-alumina carbon black 12%,

[0086] Polyethylene Wax 8%,

[0087] Vulcanizing agent S 0.1%,

[0088] Accelerator DM 0.1%,

[0089] Accelerator TMTD 0.2%,

[0090] Accelerator DTDM 2%,

[0091] Accelerator PZ 0.4%,

[0092] Anti-scorch agent 0.2%.

[0093] 1) Put EPDM rubber, zinc oxide, stearic acid, phenolic resin and anti-aging agent into pressurized banburying, then add white carbon black, silicon aluminum carbon black, calcium carbonate and polyethylene wax into banburying, the pressure It is 0.5±0.05MPa. During mixing, when the temperature rises to 80°C, lift the top bolt once, when the temperature rises to 90°C, lift the top bolt once, and when the temperature rises to 110°C, lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com