Novel WC-Cr3C2-Ni thermal spraying powder and preparation process thereof

A technology of wc-cr3c2-ni, thermal spraying powder, applied in metal material coating process, coating, fusion spraying and other directions, can solve problems such as limited application, achieve a wide range of applications, excellent crack toughness, high comprehensive The effect of performance advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

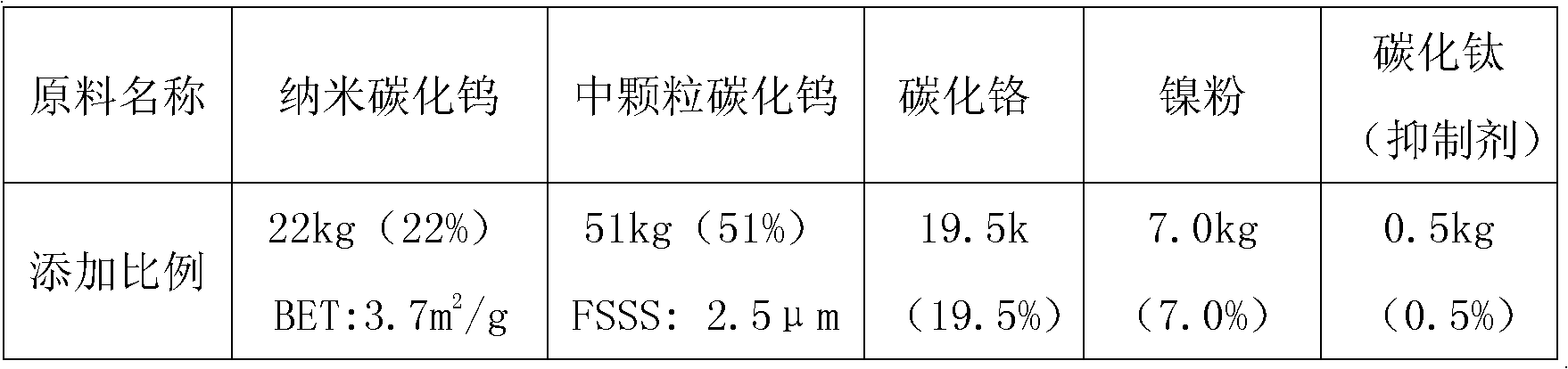

[0040] To produce new WC-Cr 3 C 2 -Ni thermal spraying powder 100kg as an example, the raw material ratio and corresponding parameters are shown in Table 3, and the process is attached.

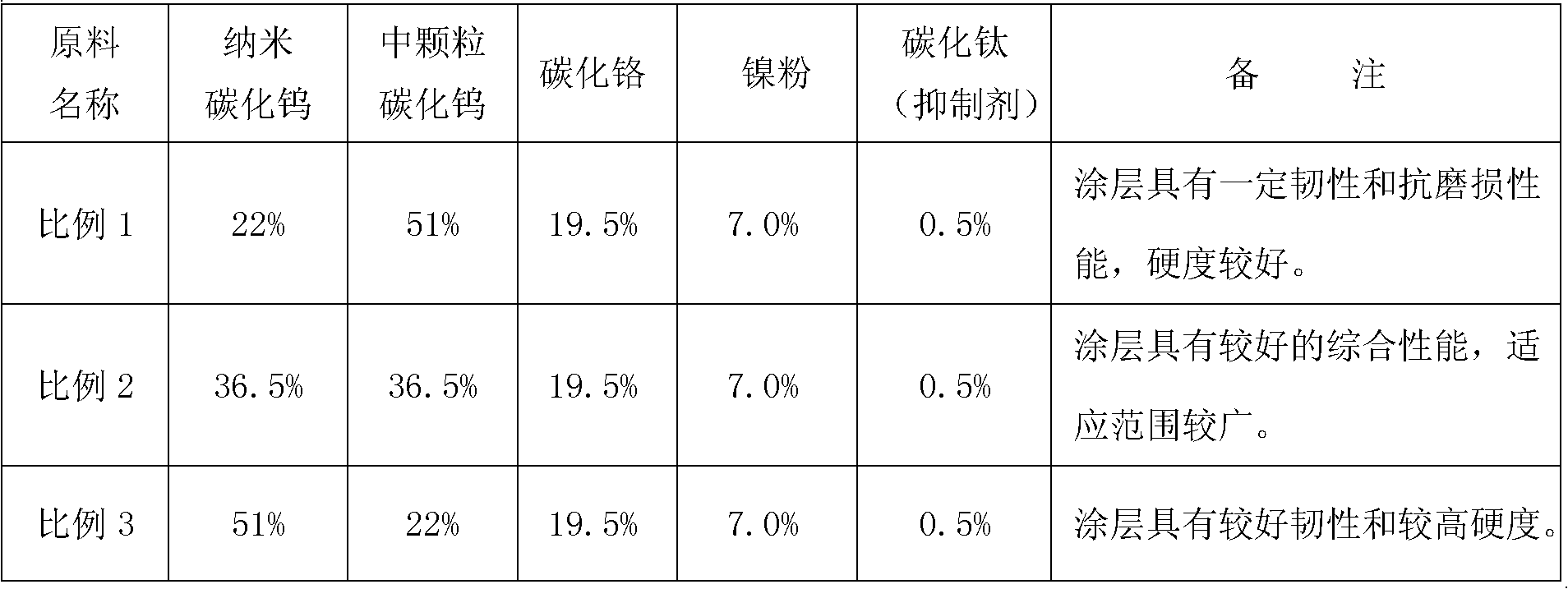

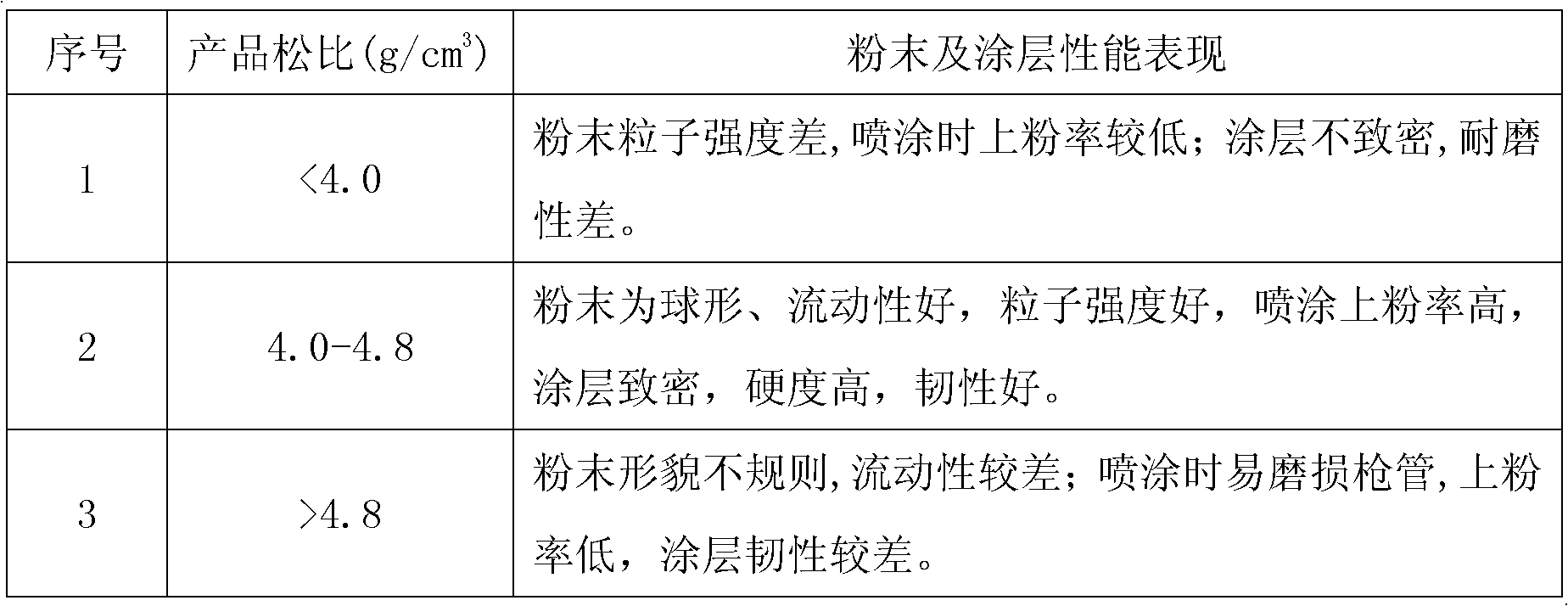

[0041] table 3

[0042]

[0043] 1. Prepare materials

[0044] Prepare nano-tungsten carbide powder according to the data in Table 3 (produced according to the patent "Preparation Method of Metal Carbide" of Inverman Corporation of the United States, patent number 2004100430580), and prepare the general-purpose medium-grained tungsten carbide product and other raw materials in the table.

[0045] 2. Mixing:

[0046] First, add 22kg (22%) nanometer tungsten carbide, 51kg (51%) medium particle tungsten carbide, 19.5kg (19.5%) chromium carbide, and 7.0kg (7.0%) nickel powder into the ball mill according to the process requirements, and then add the Raw material mass percentage is 25%, the temperature is 25kg of deionized water of 10-15 ℃ and polyvinyl alcohol of 1.0kg (1.0%) carry out mixi...

Embodiment 2

[0055] To produce new WC-Cr 3 C 2 -Ni thermal spraying powder 100kg is taken as an example, the raw material ratio and corresponding parameters are shown in Table 4, and the process is attached.

[0056] Table 4

[0057]

[0058] 1. Prepare materials

[0059] Prepare nano-tungsten carbide powder according to Table 4 (produced according to the patent of "Preparation Method of Metal Carbide" of Inverman Corporation of the United States, patent number 2004100430580), and prepare the general-purpose medium-grained tungsten carbide product and other raw materials in the table.

[0060] 2. Mixing:

[0061] First, add 36.5kg (36.5%) nanometer tungsten carbide, 36.5kg (36.5%) medium particle tungsten carbide, 19.5kg (19.5%) chromium carbide, and 7.0kg (7.0%) nickel powder into the ball mill according to the process requirements, and then Add 25kg of deionized water and 1.0kg (1.0%) of polyvinyl alcohol at a temperature of 10-15°C, accounting for 25% of the raw material mass pe...

Embodiment 3

[0070] To produce new WC-Cr 3 C 2 -Ni thermal spraying powder 100kg is taken as an example, the raw material ratio and corresponding parameters are shown in Table 5, and the process is attached.

[0071] table 5

[0072]

[0073] 1. Prepare materials

[0074] Prepare nano-tungsten carbide powder according to the data in Table 5 (produced according to the patent "Preparation Method of Metal Carbide" of Inverman Corporation of the United States, patent No. 2004100430580), and prepare the general-purpose medium-grain tungsten carbide product and other raw materials in the table.

[0075] 2. Mixing:

[0076] First, add 51kg (51%) nanometer tungsten carbide, 22kg (22%) medium particle tungsten carbide and 19.5kg (19.5%) chromium carbide into the ball mill according to the process requirements, and then add 25% of the mass percentage of raw materials at a temperature of 25kg of deionized water at 10-15°C and 1.0kg (1.0%) of polyvinyl alcohol are used for mixing. The equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com