Metal doping method of lithium iron phosphate anode material

A positive electrode material, lithium iron phosphate technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low lithium ion diffusion coefficient and poor conductivity, and achieve good conductivity, high tap density and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

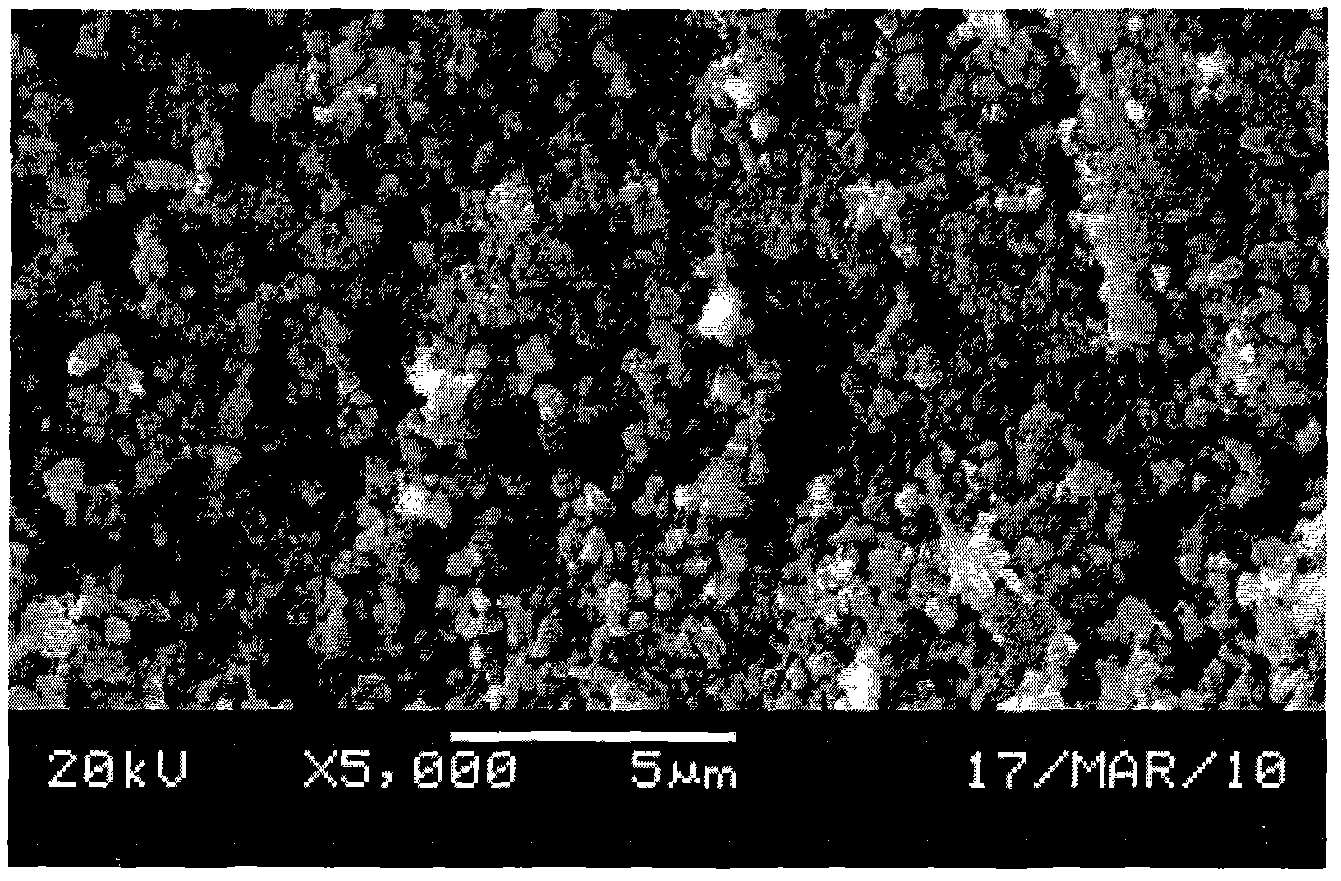

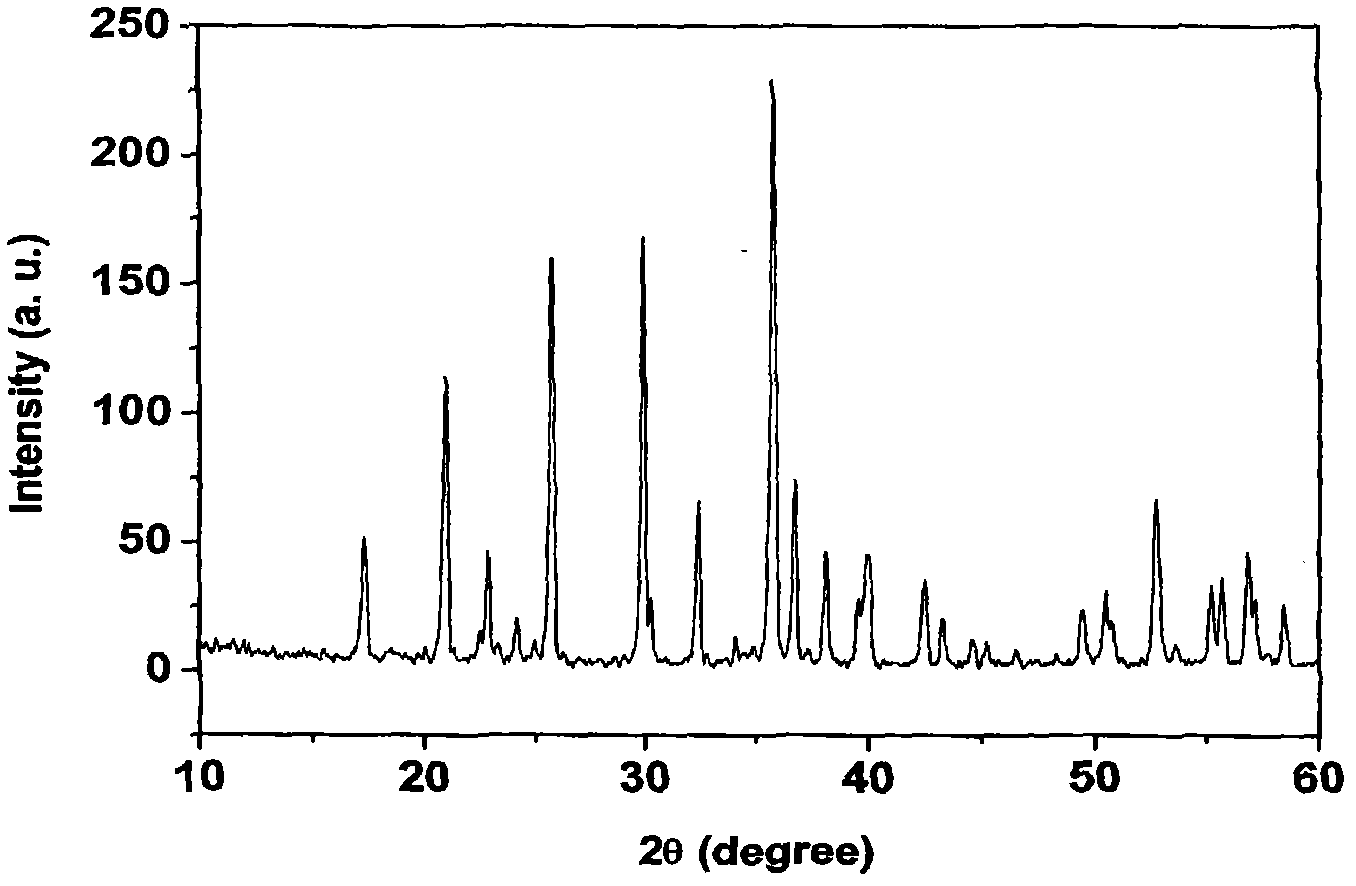

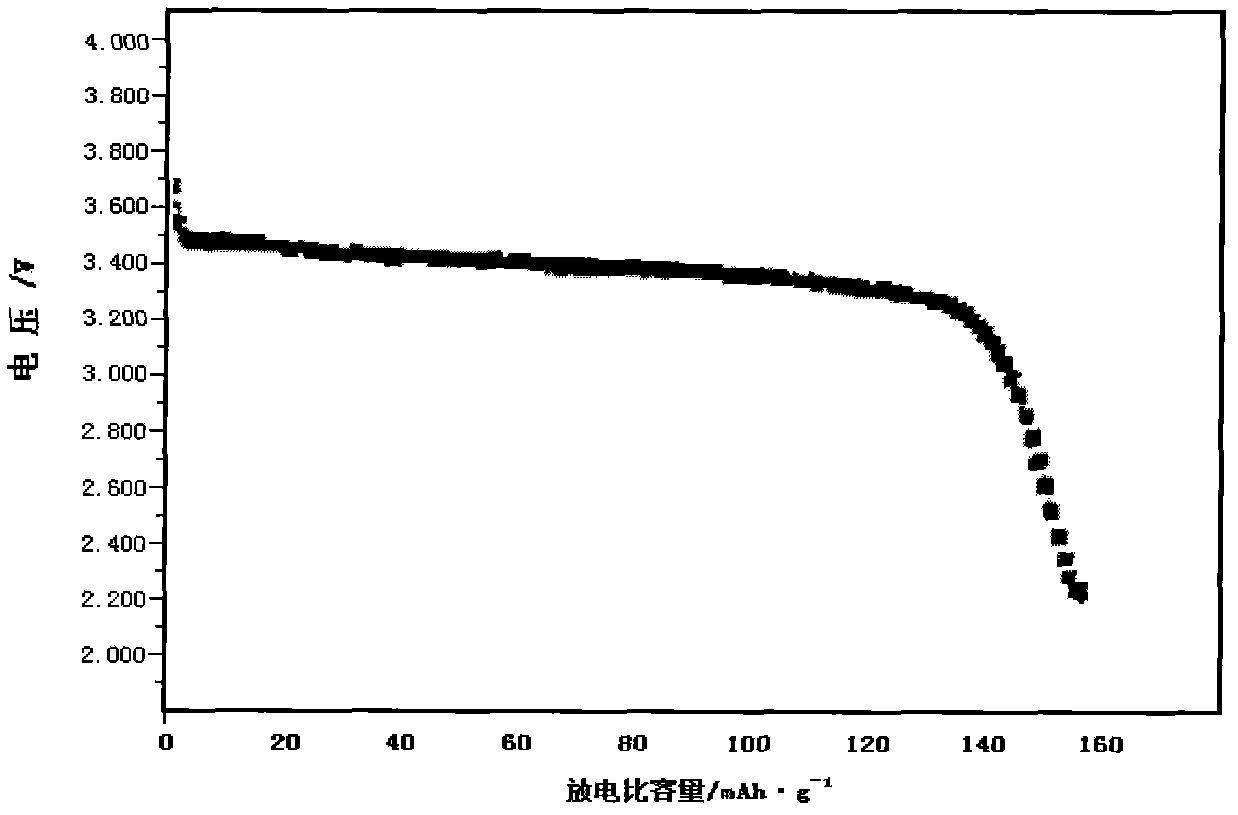

Embodiment 1

[0013] Step 1, the first grinding and mixing: first add lithium carbonate, ferrous oxalate, and ammonium dihydrogen phosphate into an ethanol dispersant with a purity greater than or equal to 95% at a molar ratio of 1.000:0.854:0.954, and then grind and mix. Grind uniformly after 1 hour, add TiO after grinding 2 And Zn(C 2 H 3 O 2 ) 2 , Lithium carbonate: TiO 2 : Zn(C 2 H 3 O 2 ) 2 The molar ratio is 1:0.02:0.02, then 7% sucrose of the mass of lithium carbonate is added, and after grinding for 1 hour, it is dried at 100°C-120°C under anaerobic conditions;

[0014] Step two, the first sintering: the material obtained by drying in step one is sintered for the first time. The method for the first sintering is to place the material obtained by drying in step one in an iron crucible and use a box-type sintering furnace. Sintering at 300℃-600℃ for 2 hours, and processing under the protection of nitrogen gas;

[0015] Step three, the second grinding and mixing: add the material sintered f...

Embodiment 2

[0020] Step 1, the first grinding and mixing: first add lithium carbonate, ferrous oxalate, and ammonium dihydrogen phosphate into an ethanol dispersant with a purity greater than or equal to 95% at a molar ratio of 1.000:0.854:0.954, and then grind and mix. Grind uniformly after 1 hour, add TiO after grinding 2 And Zn(C 2 H 3 O 2 ) 2 , Lithium carbonate: TiO 2 : Zn(C 2 H 3 O 2 ) 2 The molar ratio is 1:0.03:0.02, then 7% sucrose of the mass of lithium carbonate is added, and the grinding is continued for 1 hour, and then drying is carried out at 100°C-120°C under anaerobic conditions;

[0021] Step two, the first sintering: the material obtained by drying in step one is sintered for the first time. The method for the first sintering is to place the material obtained by drying in step one in an iron crucible and use a box-type sintering furnace. Sintering at 300℃-600℃ for 2 hours, and processing under the protection of nitrogen gas;

[0022] Step three, the second grinding and mixin...

Embodiment 3

[0027] Step 1, the first grinding and mixing: first add lithium carbonate, ferrous oxalate, and ammonium dihydrogen phosphate into an ethanol dispersant with a purity greater than or equal to 95% at a molar ratio of 1.000:0.854:0.954, and then grind and mix. Grind uniformly after 1 hour, add TiO after grinding 2 And Zn(C 2 H 3 O 2 ) 2 , Lithium carbonate: TiO 2 : Zn(C 2 H 3 O 2 ) 2 The molar ratio is 1:0.04:0.02, then 7% sucrose of the mass of lithium carbonate is added, and after grinding for 1 hour, it is dried at 100°C-120°C under anaerobic conditions;

[0028] Step two, the first sintering: the material obtained by drying in step one is sintered for the first time. The method for the first sintering is to place the material obtained by drying in step one in an iron crucible and use a box-type sintering furnace. Sintering at 300℃-600℃ for 2 hours, and processing under the protection of nitrogen gas;

[0029] Step three, the second grinding and mixing: add the material sintered f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com