Far infrared antibiosis flame-retardant temperature control blanket and manufacturing method thereof

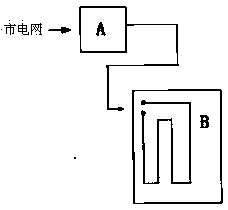

A far-infrared, temperature control system technology, used in cable/conductor manufacturing, sleeping blankets, travel blankets, etc., can solve the problems of inability to constant temperature control, high power consumption, poor safety, etc., to improve thermal efficiency, maintain temperature, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

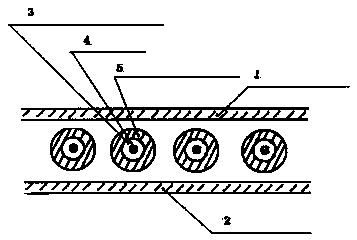

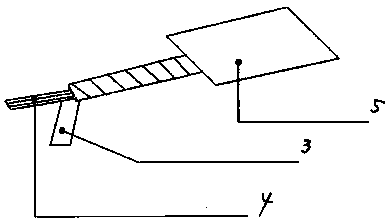

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the making of carbon-nickel composite wire.

[0020] The production process of the carbon-nickel composite wire is: carbon wire->roughening->sensitization—>activation—>nickel plating—>washing—>drying—>carbon-nickel composite wire, wherein

[0021] a. The roughening process is: configure a hydrochloric acid solution with a concentration of 4mL / L at room temperature and normal pressure, place the hydrochloric acid solution in an acid and alkali resistant plastic tank, and fix the carbon filament in an acid and alkali resistant plastic frame , put the plastic frame in the plastic tank, immerse the carbon filament in the hydrochloric acid solution, take it out after 45min, and carry out water washing and dehydration treatment;

[0022] b. The sensitization process is as follows: at room temperature and normal pressure, prepare a mixture of stannous chloride 8g / L + hydrochloric acid 16mL / L, stir the mixed solution into an acid and alkali resistant plastic tank,...

Embodiment 2

[0028] Embodiment 2: the making of antibacterial acrylic cotton fleece surface layer.

[0029] Production process: cotton acrylic fiber 1> spinning 1> knitting 1> rinsing 1> antibacterial finishing 1> brushing 1> antibacterial acrylic cotton flannelette.

[0030] After antibacterial finishing, the flannelette surface is hygienic and comfortable, has long-lasting broad-spectrum antibacterial ability against Staphylococcus aureus, and has health care functions such as deodorization, mildew resistance, and mite resistance, and is resistant to high temperature and washing. The testing standard adopts GB / T20944.2-2007 "Evaluation of Antibacterial Properties of Textiles".

Embodiment 3

[0031] Embodiment 3: the making of cotton flannelette bottom layer.

[0032] Production process: cotton fiber 1> spinning 1> weaving or knitting 1> washing, bleaching and dyeing 1> washable flame retardant finishing 1> brushing 1> flame retardant cotton flannelette.

[0033] The cotton flannelette after flame retardant finishing has the functions of durable flame retardant, high temperature resistance, washing resistance, weather aging resistance, etc.; The testing standards adopt GB / T17591-2006 "Flame Retardant Fabrics" and GB18401-2003 "National Basic Safety Technical Specifications for Textile Products (Class B)".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com