Preparation method of mulberry silk tissue engineering scaffold

A technology of tissue engineering scaffold and mulberry silk, applied in medical science, prosthesis, etc., can solve the problems of low porosity of scaffold model and inability to make models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

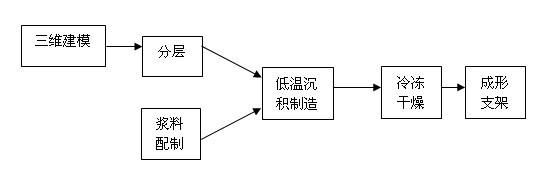

[0023] 1) Directly design with the help of 3D CAD software or use solid reverse engineering to collect the geometric shape and structural information of the prototype to obtain a 3D model.

[0024] 2) According to the above-mentioned three-dimensional model and the specific needs of the bracket, perform layering to obtain the data file formed by the low-temperature forming machine. In the layering, set the layer thickness to 0.19mm, the distance between wires to 1.3mm, and the scanning angle to 0° / 90°.

[0025] 3) slurry preparation, specifically comprising the following steps:

[0026] 3-1) Silk degumming: use 50 times the volume mass fraction of 0.5% Na 2 CO 3 solution, refine the silk twice at a temperature of 95-100° C., each time for 30-40 minutes, and rinse with deionized water for 2-3 times.

[0027] 3-2) Silk dissolution: Dissolve 10g of degummed silk in boiling 100mL CaCl with a mass fraction of 40% 2 solution, the dissolving time is 60-80 minutes, and the silk fib...

example 2

[0034] 1) Directly design with the help of 3D CAD software or use solid reverse engineering to collect the geometric shape and structural information of the prototype to obtain a 3D model.

[0035] 2) According to the above-mentioned three-dimensional model and the specific needs of the bracket, layering is carried out to obtain the data file formed by the low-temperature forming machine. In the layering, the layering thickness is set to 0.17mm, the distance between wires is 1.2mm, and the scanning angle is 0° / 90°.

[0036] 3) slurry preparation, specifically comprising the following steps:

[0037] 3-1) Silk degumming: use 50 times the volume mass fraction of 0.5% Na 2 CO 3 solution, refine the silk twice at a temperature of 95-100° C., each time for 30-40 minutes, and rinse with deionized water for 2-3 times.

[0038] 3-2) Silk dissolution: Dissolve 10g of degummed silk in boiling 100mL CaCl with a mass fraction of 40% 2 solution, the dissolving time is 60-80 minutes, and...

example 3

[0045] 1) Directly design with the help of 3D CAD software or use solid reverse engineering to collect the geometric shape and structural information of the prototype to obtain a 3D model.

[0046] 2) According to the above-mentioned three-dimensional model and the specific needs of the bracket, layering is carried out to obtain the data file formed by the low-temperature forming machine. In the layering, the layering thickness is set to 0.15mm, the distance between wires is 1.2mm, and the scanning angle is 0° / 90°.

[0047] 3) slurry preparation, specifically comprising the following steps:

[0048] 3-1) Silk degumming: use 50 times the volume mass fraction of 0.5% Na 2 CO 3 solution, refine the silk twice at a temperature of 95-100° C., each time for 30-40 minutes, and rinse with deionized water for 2-3 times.

[0049] 3-2) Silk dissolution: Dissolve 10g of degummed silk in boiling 100mL CaCl with a mass fraction of 40% 2 solution, the dissolving time is 60-80 minutes, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com