High-yield acetate brewing yeast engineering bacteria

A technology of Saccharomyces cerevisiae and acetate, applied in the field of bioengineering, can solve the problems of low ester production capacity of Saccharomyces cerevisiae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

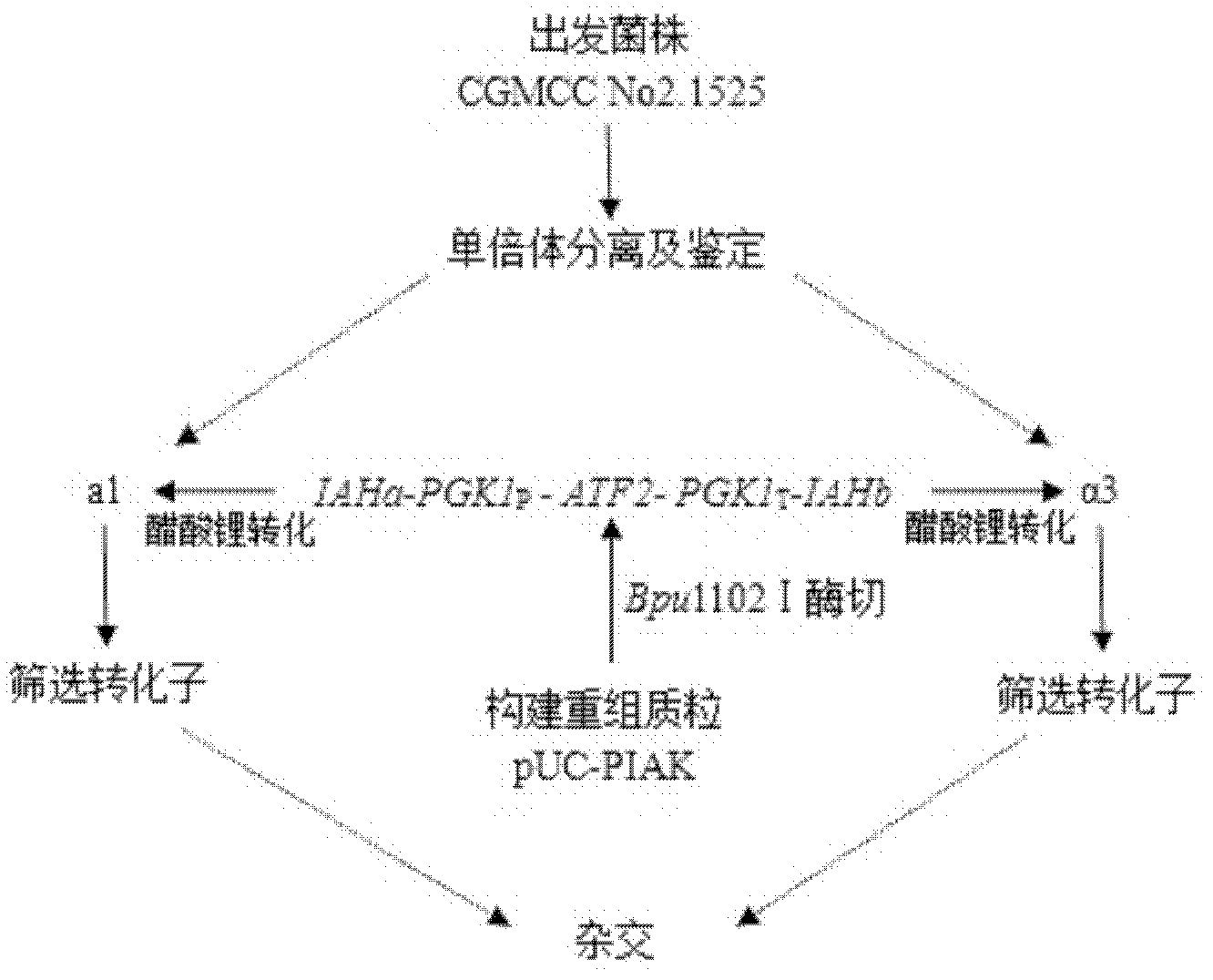

[0028] Embodiment 1: Construction of high-yielding Saccharomyces cerevisiae genetically engineered bacteria

[0029] (1) Construction of genetically engineered strains

[0030] 1) Ligate the PGK1 promoter and terminator with the pUC19 plasmid to obtain pUC-PGK1;

[0031] 2) Ligate the homologous fragment IAH derived from Saccharomyces cerevisiae to the pUC-PGK1 obtained in step 1) to obtain pUC-PGK1-IAH;

[0032] 3) inserting the gene encoding alcohol acetyltransferase ATF2 into the pUC-PGK1-IAH obtained in step 2) between the PGK1 promoter and the terminator to obtain pUC-PGK1-IAH-ATF2;

[0033] 4) connecting the kan gene to the pUC-PGK1-IAH-ATF2 obtained in step 3) to obtain the plasmid pUC-PGK1-IAH-ATF2-kan (hereinafter referred to as pUC-PIA2K);

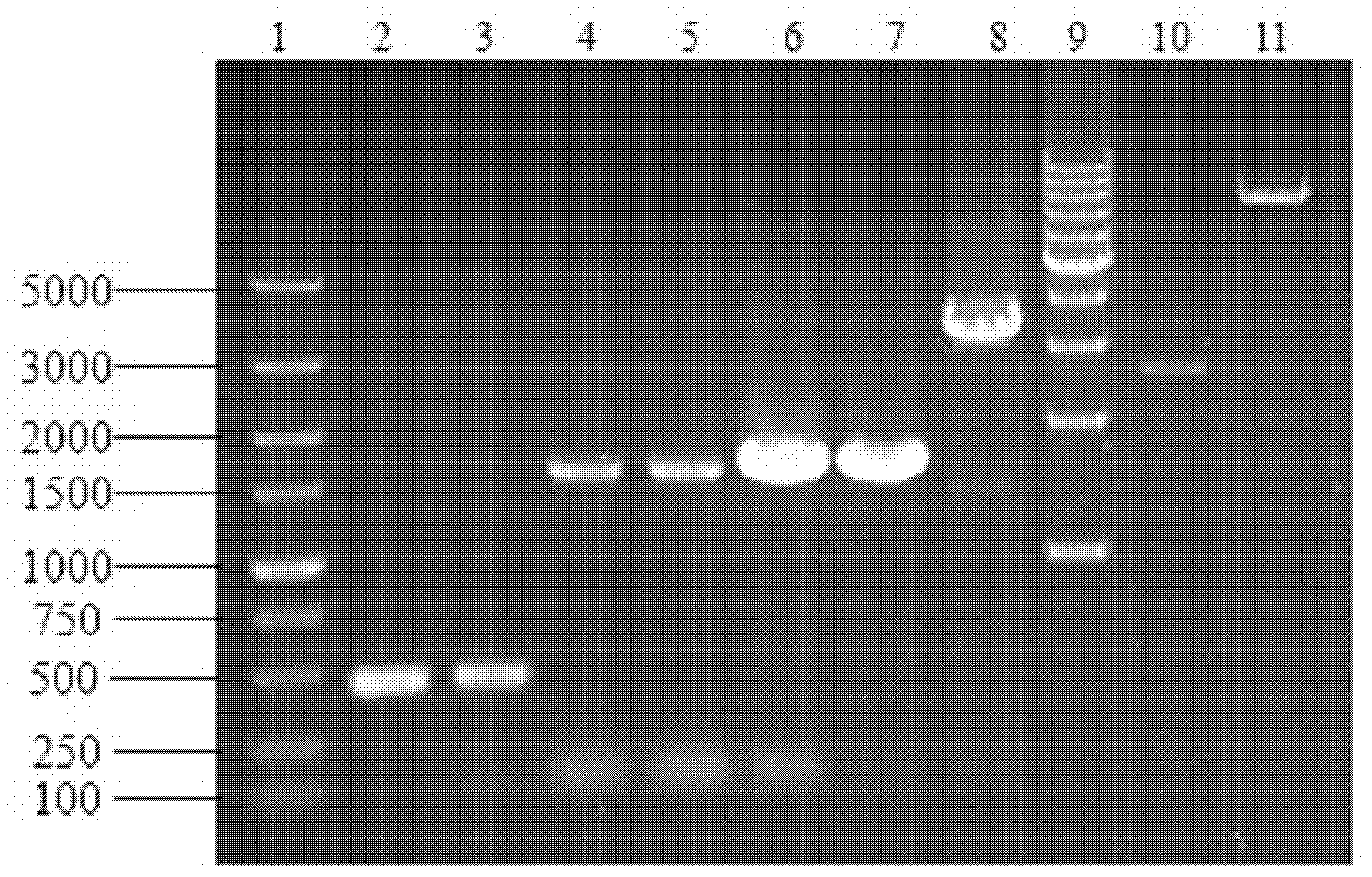

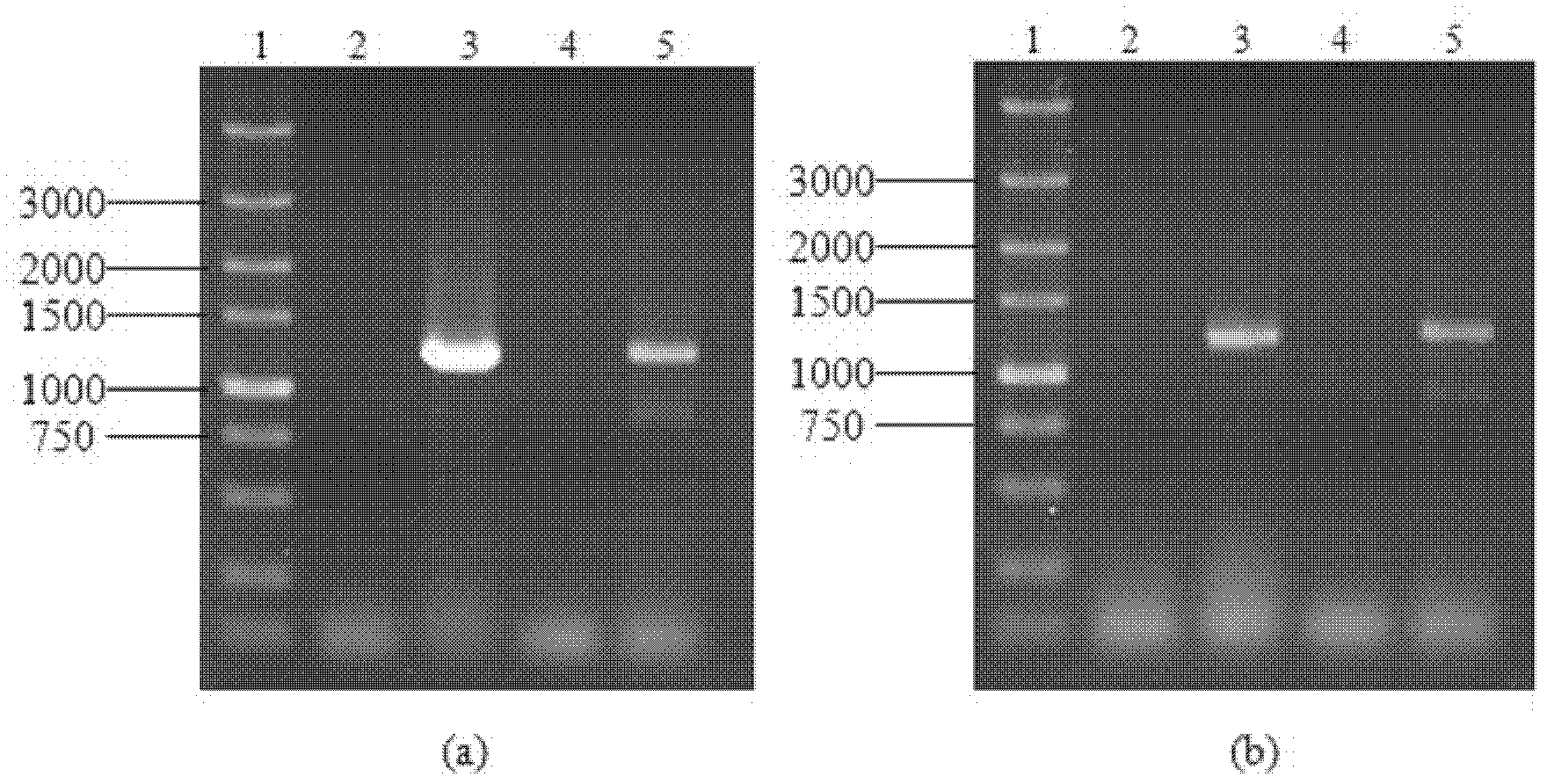

[0034] figure 1 It is the verification electropherogram of the pUC-PIA2K plasmid: where lane 1 is the 5000bp DNALadder Marker; lane 2 is the homologous fragment IAH amplified by the genome of the recipient strain; lane 3 is th...

Embodiment 2

[0043] Example 2: Research on the fermentation performance of high-yielding Saccharomyces cerevisiae engineering bacteria and starting strains

[0044] The engineering bacteria and acceptor bacteria obtained in Example 1 were respectively inserted into 5 mL of wort culture solution, and cultured overnight at 30° C. for 12 hours; all the bacterial liquids were transferred to 20 mL of fresh wort culture solution, and cultivated at 30° C. for 24 hours. Take 100g of japonica rice and place it in water at 25-30°C for 72 hours; take it out, wash it, and cook it under normal pressure for 30 minutes. Cool the rice, put it into a 500mL conical flask, add 10g of cooked wheat koji and 105mL of water. Finally, 25 mL of yeast wort culture liquid was inserted and fermented at 28° C. for 5 days. Oscillate and weigh every 12 hours during the fermentation period, and record the weight loss; after the fermentation is over, stop the cultivation and weigh; measure the residual sugar concentratio...

Embodiment 3

[0048] Example 3: Research on the Fermentation Performance of High Ester Yield Saccharomyces cerevisiae Engineering Haploids and Haploids of Starting Strains

[0049] Put the engineering haploid (type a / α) and the haploid of the recipient bacteria (type a / α) into 5mL wort culture solution, culture overnight at 30°C for 12h; transfer all the bacteria solution to 20mL fresh wort Incubate at 30°C for 24 hours in the culture medium. Take 100g of japonica rice and place it in water at 25-30°C for 72 hours; take it out, wash it, and cook it under normal pressure for 30 minutes. Cool the rice, put it into a 500mL conical flask, add 10g of cooked wheat koji and 105mL of water. Finally, 25 mL of yeast wort culture liquid was inserted and fermented at 28° C. for 5 days. Oscillate and weigh every 12 hours during the fermentation period, and record the weight loss; after the fermentation is over, stop the cultivation and weigh; measure the residual sugar concentration, alcohol volume fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com