Preparation method of insulator silicon dioxide film in MIM (metal-insulator-metal) type capacitor

A technology of silicon dioxide and insulators, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of poor film properties, poor barrier film quality, low thermal oxygen reaction, etc., achieve good electrical stability, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

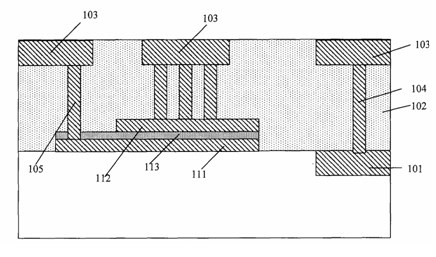

[0027] Figure 4 It is the process flow chart of the preparation method of silicon dioxide film of insulator in the MIM type electric capacity of the present invention;

[0028] Figure 5-9 It is a schematic structural flow diagram of a method for preparing an insulator silicon dioxide film in a MIM type capacitor of the present invention.

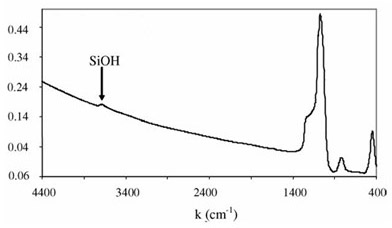

[0029] Such as Figure 4-9 As shown, a wafer is provided as a substrate 1, after stabilizing the gas flow, pressure and temperature of the SACVD equipment, the substrate 1 is placed in the SACVD equipment, and the first layer of silicon dioxide film 2 is deposited on the substrate 1, Afterwards, a passivation dehydrogenation treatment process 11 is carried out for 5-50 minutes using a mixed gas containing active oxygen atoms or ozone gas to remove H in Si-H in the first layer of silicon dioxide film 2; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com