Imidazole high-acidity ionic liquid catalyst and application thereof

A technology of ionic liquid and catalyst, which is applied in the field of green and renewable energy, can solve the problems of limited acidity of ionic liquid, restrict large-scale application, increase cost, etc., and achieve the effect of simplifying post-treatment process, reducing application cost and increasing acid density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

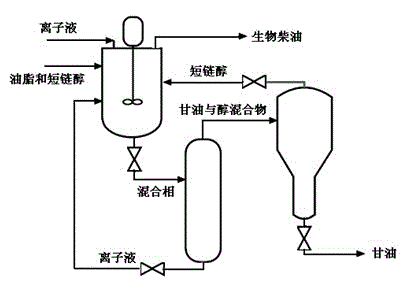

Image

Examples

Embodiment 1

[0026] Embodiment 1: This imidazole strong acidic ionic liquid catalyst is bisimidazole butane sulfonic acid ionic liquid catalyst with hydrogen sulfate, and the chemical structural formula is as follows:

[0027] , where X is HSO 4 - , m=2; n=4.

[0028] The synthetic method of this ionic liquid catalyst is as follows:

[0029] 1) 0.5 mol imidazole and 0.5 mol sodium ethoxide were dissolved in 50 ml ethanol solvent, stirred and reacted at 70°C for 8 hours, the solvent ethanol was removed by rotary evaporation, washed with ether three times, dried in a vacuum oven for 12 hours, and an intermediate of sodium imidazole was obtained.

[0030] 2) Dissolve 0.5mol imidazole sodium and 0.25mol 1,2-dibromoethane in 50ml ethanol, mix well, stir and reflux for 10h, filter, wash the filtrate three times with ether, and vacuum dry to obtain bisimidazole intermediate.

[0031] 3) 0.5 mol of 1,4-sultone was added to the toluene solution of bis-imidazole, mixed and stirred for 8 hours,...

Embodiment 2

[0034] Embodiment 2: This imidazole strong acidic ionic liquid catalyst is dihydrogen phosphate diimidazole propane sulfonic acid ionic liquid catalyst, and the chemical structural formula is as follows:

[0035] , where X is H2 PO 4 - , m=2; n=3.

[0036] The synthetic method of this ionic liquid catalyst is as follows:

[0037] 1) 0.5 mol imidazole and 0.5 mol sodium ethoxide were dissolved in 50 ml ethanol solvent, stirred and reacted at 70°C for 8 hours, the solvent ethanol was removed by rotary evaporation, washed with ether three times, dried in a vacuum oven for 12 hours, and an intermediate of sodium imidazole was obtained.

[0038] 2) Dissolve 0.5mol imidazole sodium and 0.25mol 1,2-dibromoethane in 50ml ethanol, mix well, stir and reflux for 10h, filter, wash the filtrate three times with ether, and vacuum dry to obtain bisimidazole intermediate.

[0039] 3) 0.5 mol of 1,3-propane sultone was added to the toluene solution of bis-imidazole, mixed and stirred for ...

Embodiment 3

[0042] Embodiment 3: this imidazoles strongly acidic ionic liquid catalyst is bisimidazole butane sulfonic acid ionic liquid catalyst with hydrogen sulfate, and the chemical structural formula is as follows:

[0043] , where X is HSO 4 - , m=4; n=4.

[0044] The synthetic method of this ionic liquid catalyst is as follows:

[0045] 1) 0.5 mol imidazole and 0.5 mol sodium ethoxide were dissolved in 50 ml ethanol solvent, stirred and reacted at 70°C for 8 hours, the solvent ethanol was removed by rotary evaporation, washed with ether three times, dried in a vacuum oven for 12 hours, and an intermediate of sodium imidazole was obtained.

[0046] 2) Dissolve 0.5mol imidazole sodium and 0.25mol 1,4-dibromobutane in 50ml ethanol, mix well, stir and reflux for 10h, filter, wash the filtrate three times with ether, and vacuum dry to obtain bisimidazole intermediate.

[0047] 3) 0.5 mol of 1,4-sultone was added to the toluene solution of bis-imidazole, mixed and stirred for 8 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com