Method for preparing split-phase black fancy glaze by utilizing industrial slag

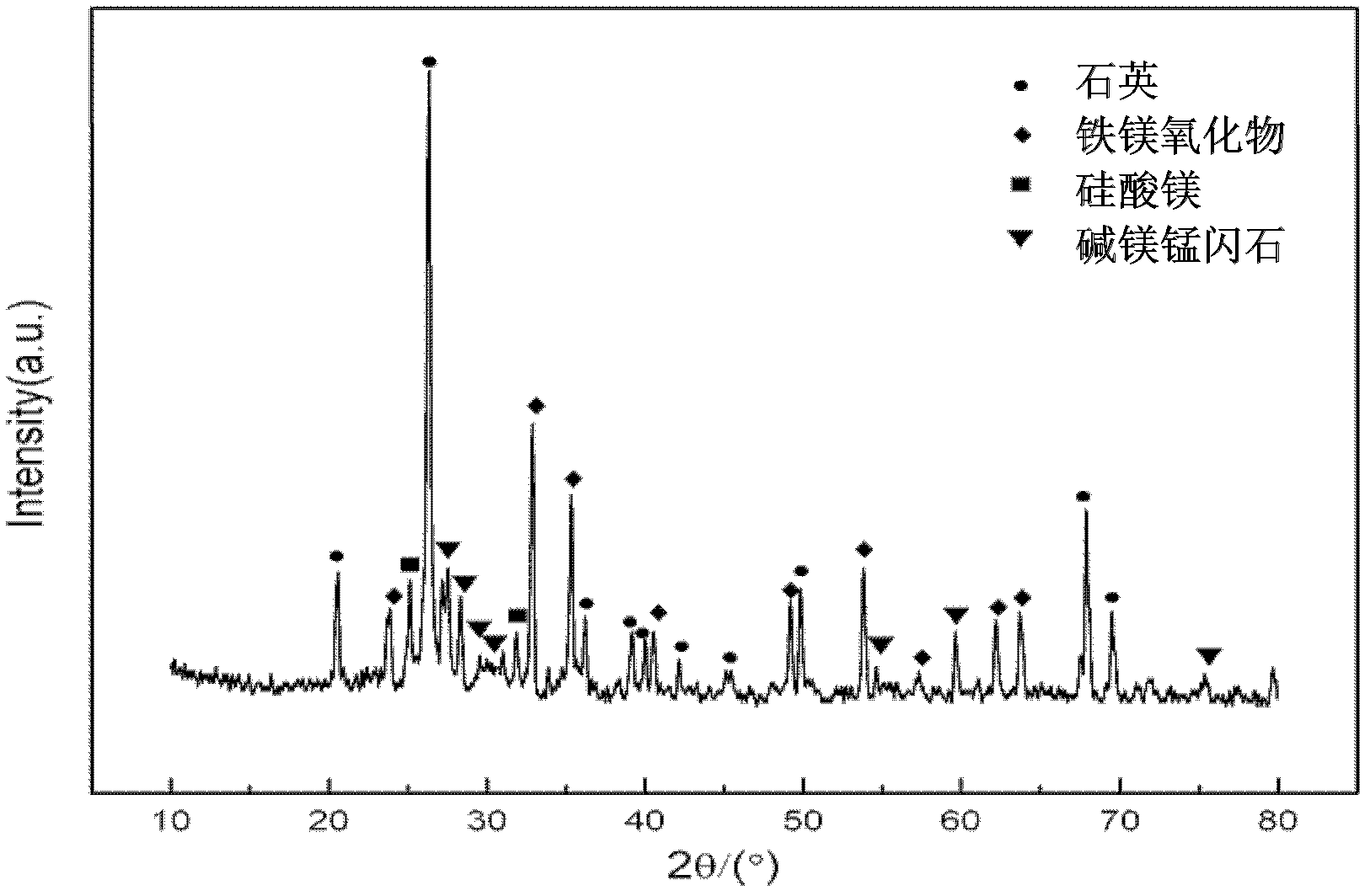

The technology of slag and flower glaze is applied in the field of preparation of phase-separated black flower glaze, which can solve the problems of complex process, large pollution, non-conformity, etc., and achieve the effects of high blackness, low cost and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Preparation of fine slag:

[0020] Grind the industrial slag evenly in a mortar, put it into a crucible and calcinate it in a high-temperature furnace to 1000°C, keep it warm for 60 minutes, and then cool it naturally. After cooling, ball mill it at a speed of 900r / h for 30 minutes. Sieve to get fine slag;

[0021] 2) Preparation of glaze slurry:

[0022] Mix 50% feldspar, 10% quartz, 10% calcite, 2% talc, 3.0% calcium phosphate, and 25% fine slag to obtain a mixture by mass percentage, and then add 0.4% of the mass of the mixture to the mixture Sodium tripolyphosphate and 1% CMC are mixed evenly, finely ground to 250 mesh, and the specific gravity of the prepared glaze slurry is 1.7g / cm 3 ;

[0023] 3) Apply the glaze slurry evenly on the green body, raise the temperature to 1250°C, keep it warm for 50 minutes and cool it naturally to obtain the phase-separated black flower glaze.

[0024] Table one is the test result parameter of embodiment 1;

[0025]

[0...

Embodiment 2

[0030] 1) Preparation of fine slag:

[0031] Grind the industrial slag evenly in a mortar, put it into a crucible and calcinate it in a high-temperature furnace to 1000°C, keep it warm for 60 minutes, and then cool it naturally. After cooling, ball mill it at a speed of 900r / h for 30 minutes. Mesh sieve to get fine slag;

[0032] 2) Preparation of glaze slurry:

[0033] By mass percentage, 55% feldspar, 20% quartz, 8% calcite, 2% calcium phosphate, and 15% fine slag are mixed to obtain a mixture, and then 0.4% sodium tripolyphosphate and sodium tripolyphosphate are added to the mixture. 1% CMC is mixed evenly, finely ground to 250 mesh, and the specific gravity of the prepared glaze slurry is 1.7g / cm 3 ;

[0034] 3) Apply the glaze slurry evenly on the body, raise the temperature to 1230°C, keep it warm for 40 minutes and cool naturally to obtain the phase-separated black flower glaze.

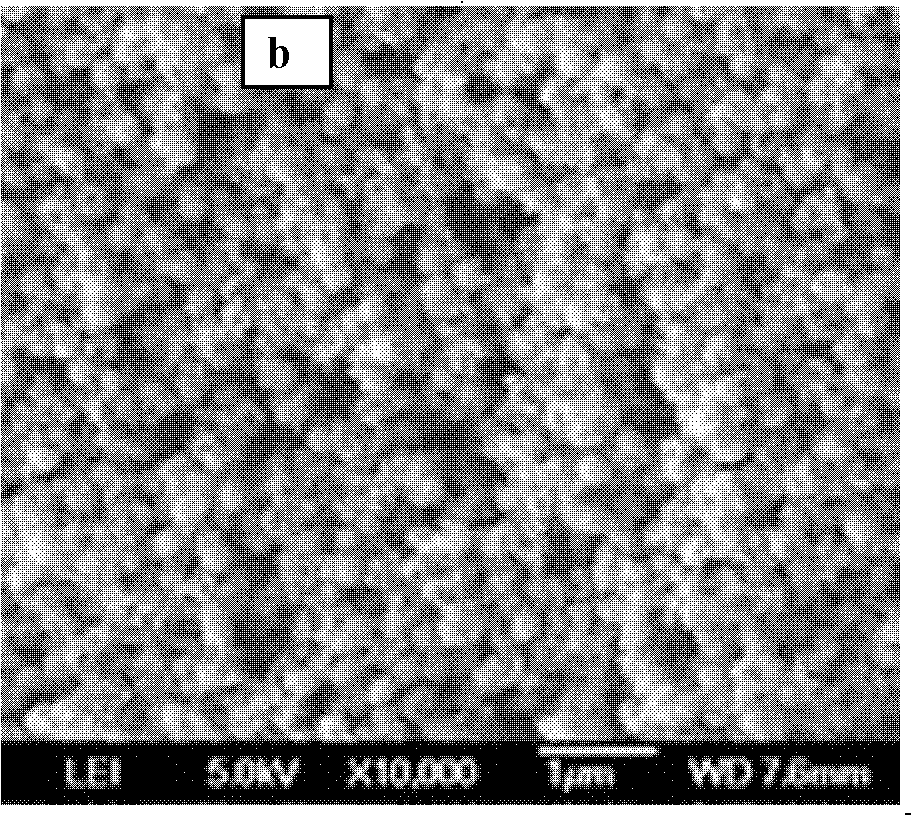

[0035] Depend on image 3 It can be seen from the photo that the present invention pr...

Embodiment 3

[0037] 1) Preparation of fine slag:

[0038] Grind the industrial slag evenly in a mortar, put it into a crucible and calcinate it in a high-temperature furnace to 1000°C and keep it warm for 60 minutes, then cool it naturally, after cooling, ball mill it at a speed of 900r / h for 30 minutes, take it out and pass it through an 80-mesh sieve , to get fine slag;

[0039] 2) Preparation of glaze slurry:

[0040] Mix 60% feldspar, 15% quartz, 6% calcite, 5% talc, 1.0% calcium phosphate, and 13% fine slag to obtain a mixture by mass percentage, and then add 0.4% of the mass of the mixture to the mixture Sodium tripolyphosphate and 1% CMC are mixed evenly, finely ground to 250 mesh, and the specific gravity of the prepared glaze slurry is 1.7g / cm 3 ;

[0041] 3) Apply the glaze slurry evenly on the body, raise the temperature to 1220°C, keep it warm for 40 minutes and cool naturally to obtain the phase-separated black flower glaze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com