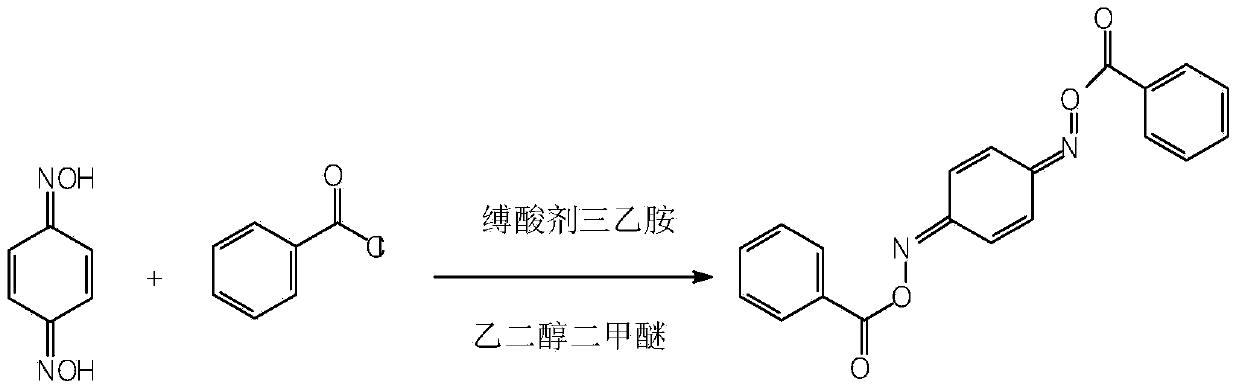

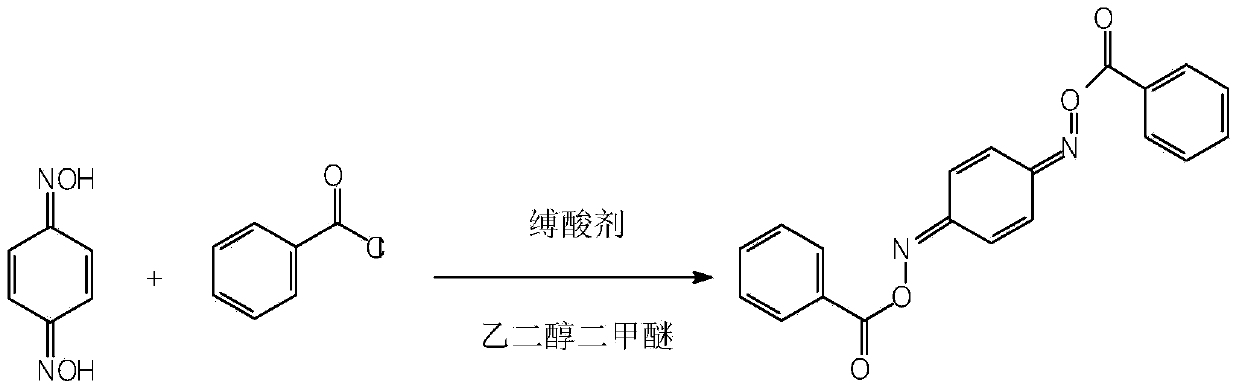

Manufacture method of p, p-dibenzoylquinone dioxime compounds

A technology of dibenzoylbenzoquinone dioxime and p-benzoquinone dioxime, which is applied in the right field, can solve the problems of increasing product production cost, low product yield, and low purity of finished products, and achieves production cost reduction and product purity. High and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Add 10g of p-benzoquinone dioxime (0.0724mol) into a 250ml four-necked flask, then add 60g of ethylene glycol dimethyl ether, stir evenly, and slowly add 1.46g of triethylamine ( 0.0145mol) and 25.44g benzoyl chloride (0.181mol), after the dropwise completion, the reaction was incubated at room temperature for 2 hours.

[0015] After the heat preservation is finished, filter and reclaim the filtrate, wash the filter cake twice with 10g ethylene glycol dimethyl ether (5g each time), reclaim the washing liquid, wash once with 10ml water, and drain to obtain the product p-para-benzophenone Acylbenzoquinone dioxime was placed in an oven and dried at 90°C to obtain 23.98 g of the finished product, with a yield (based on p-benzoquinone dioxime) of 95.61% and a purity of 96.2% (HPLC).

Embodiment 2

[0017] Add 10g of p-benzoquinone dioxime (0.0724mol) into a 250ml four-necked flask, then add 60g of ethylene glycol dimethyl ether, stir evenly, and slowly add 1.06g of N,N-dimethoxy Methylformamide (0.0145 mol) and 25.44 g of benzoyl chloride (0.181 mol) were left to react at room temperature for 2 hours after the dropwise completion.

[0018] After the heat preservation is finished, filter and reclaim the filtrate, wash the filter cake twice with 10g ethylene glycol dimethyl ether (5g each time), reclaim the washing liquid, wash once with 10ml water, and drain to obtain the product p-para-benzophenone Acylbenzoquinone dioxime was dried in an oven at 90°C to obtain 23.7 g of the finished product, with a yield (calculated as p-benzoquinone dioxime) of 94.50% and a purity of 95.3% (HPLC).

Embodiment 3

[0020] Add 10g of p-benzoquinone dioxime (0.0724mol) into a 250ml four-necked flask, then add 60g of ethylene glycol dimethyl ether, stir evenly, and slowly add 1.15g of pyridine (0.0145mol ) and 25.44g benzoyl chloride (0.181mol), after the dropwise completion, the reaction was incubated at room temperature for 2 hours.

[0021] After the heat preservation is finished, filter and reclaim the filtrate, wash the filter cake twice with 10g ethylene glycol dimethyl ether (5g each time), reclaim the washing liquid, wash once with 10ml water, and drain to obtain the product p-para-benzophenone Acylbenzoquinone dioxime was placed in an oven and dried at 90°C to obtain 23.8 g of finished product, the yield (based on p-benzoquinone dioxime) was 94.89%, and the purity was 95.5% (HPLC)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com