Method for separating and purifying naringin and neohesperidin from white skin layer of citrus grandis

A new hesperidin, separation and purification technology, applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., can solve problems such as unfavorable mass production, low process efficiency, long production cycle, etc., and achieve safe and easy production process. The effect of simple operation and synthesis process and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 The operation method of the present invention for separating and purifying naringin and neohesperidin is carried out according to the following two steps:

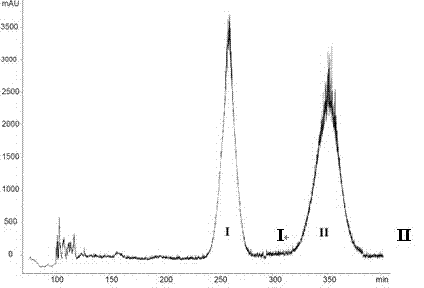

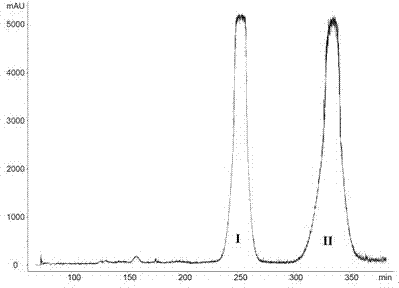

[0022] see figure 1 , (1) Preparation of macroporous resin crude extract powder: 8 g dried Huyou white cortex was extracted twice with 80% ethanol (solid-liquid ratio 1:25) ultrasonically (40 °C), centrifuged at 4000 rpm for 20 min, The two supernatants were combined and evaporated to dryness on a rotary evaporator to obtain the extract, which was dissolved in ddH 2 In O, about 200 mL of D101 macroporous resin was applied, the bed volume (BV) was 20 mL, and the sample flow rate was 2 mL / min. After loading, the D101 macroporous resin was first washed with water for 4 BV to remove impurities, then naringin and neohesperidin were eluted with 60% ethanol, and 8 BV were eluted until no naringin and neohesperidin could be detected in the effluent. Hesperidin, the elution flow rate was 2 mL / min, 60% of the elue...

Embodiment 2

[0025] The operation method of separating and purifying naringin and neohesperidin of the present invention is carried out according to the following two steps:

[0026] see figure 1 , (1) Preparation of macroporous resin crude extract powder: 16 g dried Huyou white cortex was extracted twice with 80% ethanol (solid-liquid ratio 1:25) ultrasonically (40 °C), centrifuged at 4000 rpm for 20 min, The two supernatants were combined and evaporated to dryness on a rotary evaporator to obtain the extract, which was dissolved in ddH 2 In O, about 400 mL of D101 macroporous resin was applied, the bed volume (BV) was 20 mL, and the sample flow rate was 2 mL / min. The loaded D101 macroporous resin was first washed with water for 4 BV to remove impurities, and then 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80% ethanol was used to elute naringin and 80% ethanol. Neohesperidin, washed 4 BV per gradient, the elution flow rate was 2 mL / min, combined 10%-60% eluent, evaporated to dryness on a rotary...

Embodiment 3

[0028] Example 3 The present invention screened and determined the influencing factors through the following tests

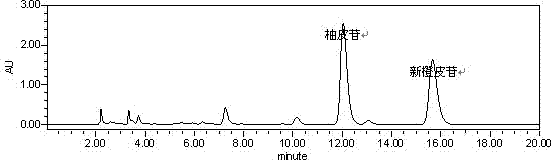

[0029] 1. Selection of purification materials

[0030] The fresh Huyou fruit is divided into four different parts: oil cell layer, white skin layer, capsule coat, and juice cell. The four different parts are dried in an oven at 50°C to constant weight, crushed with a sample mill, and passed through a 40-mesh sieve. Accurately weigh a certain amount of dry sample powder from four different parts of Huyou, extract with 80% ethanol (solid-to-liquid ratio 1:25) ultrasonically for 40 min (30°C), and centrifuge the extract on a centrifuge at 4000 rpm for 20 min, and repeat the process. Twice, the supernatants were pooled for HPLC analysis of naringin and neohesperidin. HPLC mobile phases include ddH 2 Chromatography of O (A) and acetonitrile (B) using isocratic elution of A:B=79:21, flow rate of 1 mL / min, and detection wavelength of 280 nm. The results showed that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com