Desugared and decolored soapberry saponin and preparation method thereof

A technology of sapindus saponin and sapindus pericarp, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc. It can solve the problems of restricting product quality and application, the existence of flocculent substances, and the opacity of the solution. Achieve the effect of improving product purity, product color becoming lighter, and product solution clarification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

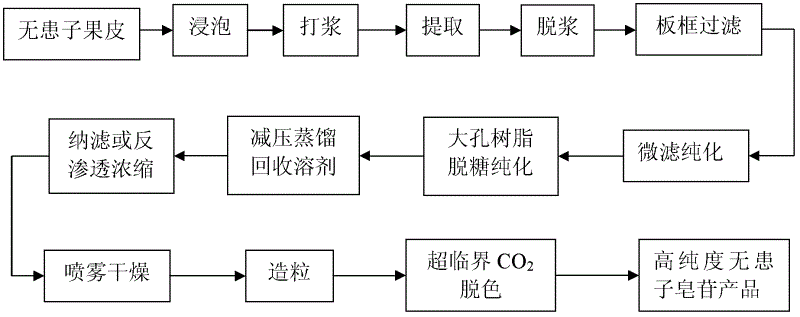

Image

Examples

Embodiment 1

[0035] A preparation method for desugaring and decoloring Sapindus sapinsin, the steps and conditions thereof are as follows:

[0036] Step 1: Raw material pretreatment and extraction

[0037] (1) Soak the Sapindus fruit peel in clear water at 10°C for 120 minutes;

[0038] (2) The soaked Sapindus fruit peel is pulverized to 10 orders with a colloid mill;

[0039] (3) Put the crushed Sapindus fruit peel and the aqueous solution containing 1‰ organosilicon defoamer into the extraction tank with a mass ratio of 1:2 for extraction, extract three times, and combine the three extracts, wherein the extraction temperature is 25 ℃, the extraction time is 24h;

[0040] (4) Desizing the extracted fruit pomace with a desizing machine, and merging the obtained liquid with the extract;

[0041] Step 2: Filtration and purification

[0042] (1) The combined liquid is filtered by a plate and frame filter with a filter cloth of 48 μm, wherein the pressure is 0.1 MPa;

[0043] (2) The liqu...

Embodiment 2

[0054] A preparation method for desugaring and decoloring Sapindus sapinsin, the steps and conditions thereof are as follows:

[0055] Step 1: Raw material pretreatment and extraction

[0056](1) Soak Sapindus fruit peel in clear water at 30°C for 30 minutes;

[0057] (2) The soaked Sapindus fruit peel is pulverized to 50 orders with a colloid mill;

[0058] (3) Put the crushed Sapindus fruit peel and the aqueous solution containing 3‰ polyether modified silicon defoamer into the extraction tank with a mass ratio of 1:4 for extraction, extract three times, and combine the three extracts. The temperature is 55°C, and the extraction time is 3h;

[0059] (4) Desizing the extracted fruit pomace with a desizing machine, and merging the obtained liquid with the extract;

[0060] Step 2: Filtration and purification

[0061] (1) Filter the combined liquid with a 13 μm plate and frame filter, where the pressure is 0.5 MPa;

[0062] (2) The liquid filtered by the plate and frame is...

Embodiment 3

[0073] A preparation method for desugaring and decoloring Sapindus sapinsin, the steps and conditions thereof are as follows:

[0074] Step 1: Raw material pretreatment and extraction

[0075] (1) Soak the Sapindus fruit peel in clear water at 50°C for 5 minutes;

[0076] (2) The soaked Sapindus pericarp is pulverized to 100 orders with a beater;

[0077] (3) Put the crushed Sapindus fruit peel and the aqueous solution containing 5‰ polyether modified silicon defoamer into the extraction tank with a mass ratio of 1:6 for extraction, extract three times, and combine the three extracts, and extract The temperature is 85°C, and the extraction time is 10 minutes;

[0078] (4) Desizing the extracted fruit pomace with a desizing machine, and merging the obtained liquid with the extract;

[0079] Step 2: Filtration and purification

[0080] (1) filter the combined liquid with a filter cloth aperture of 0.8 μm plate and frame filter, wherein the pressure is 0.8 MPa;

[0081] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com