Preparation method and application of ZnO/TiO2 composite powder

A composite powder and mixed liquid technology, which is applied in the direction of biocide-containing paint, antifouling/underwater paint, and radiation-absorbing paint, etc., can solve the problem of easy introduction of impurities, poor performance, large particle size of composite powder, etc. problem, to achieve the effect of good controllability, good scattering ability, and small original particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Dissolve 0.002mol zinc acetate and 0.4g (0.001148mol) sodium dodecylbenzenesulfonate in ethanol, then add 0.004mol tetrabutyl titanate, and mix to obtain 10mL raw material solution;

[0052] 2) under stirring condition, in the raw material liquid in step 1), add dropwise the sodium hydroxide aqueous solution of 10mL, the concentration of sodium hydroxide in the sodium hydroxide aqueous solution is 4mol / L, and the rate of addition of the sodium hydroxide aqueous solution is 1mL / min, the dropping time is 10min;

[0053] 3) The mixture in step 2) was reacted in an autoclave at 160°C for 12h. After centrifugation, it was washed 3 times with distilled water and then 3 times with ethanol, and dried at 80°C for 12h to obtain 0.42g of ZnO / TiO 2 Composite powder.

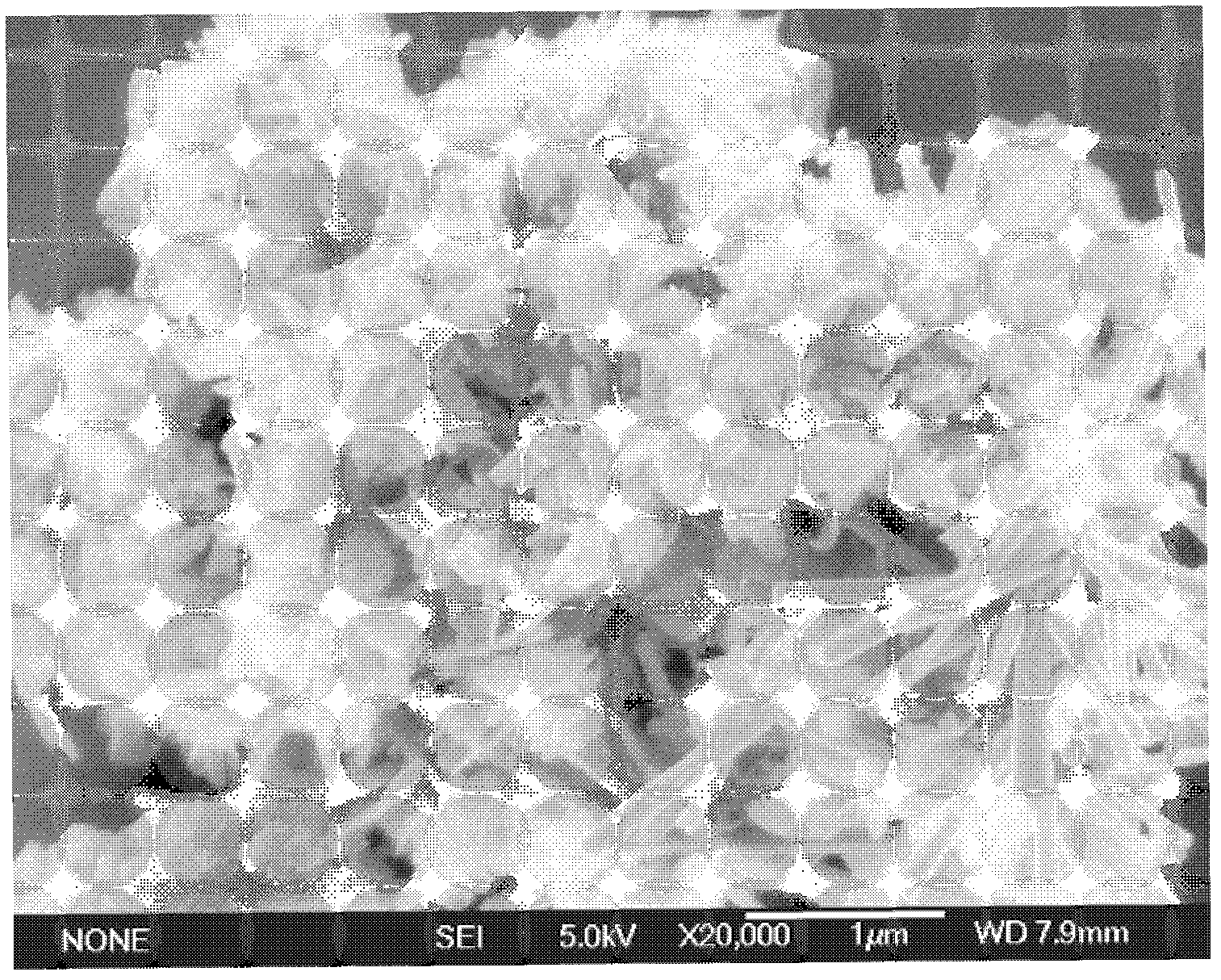

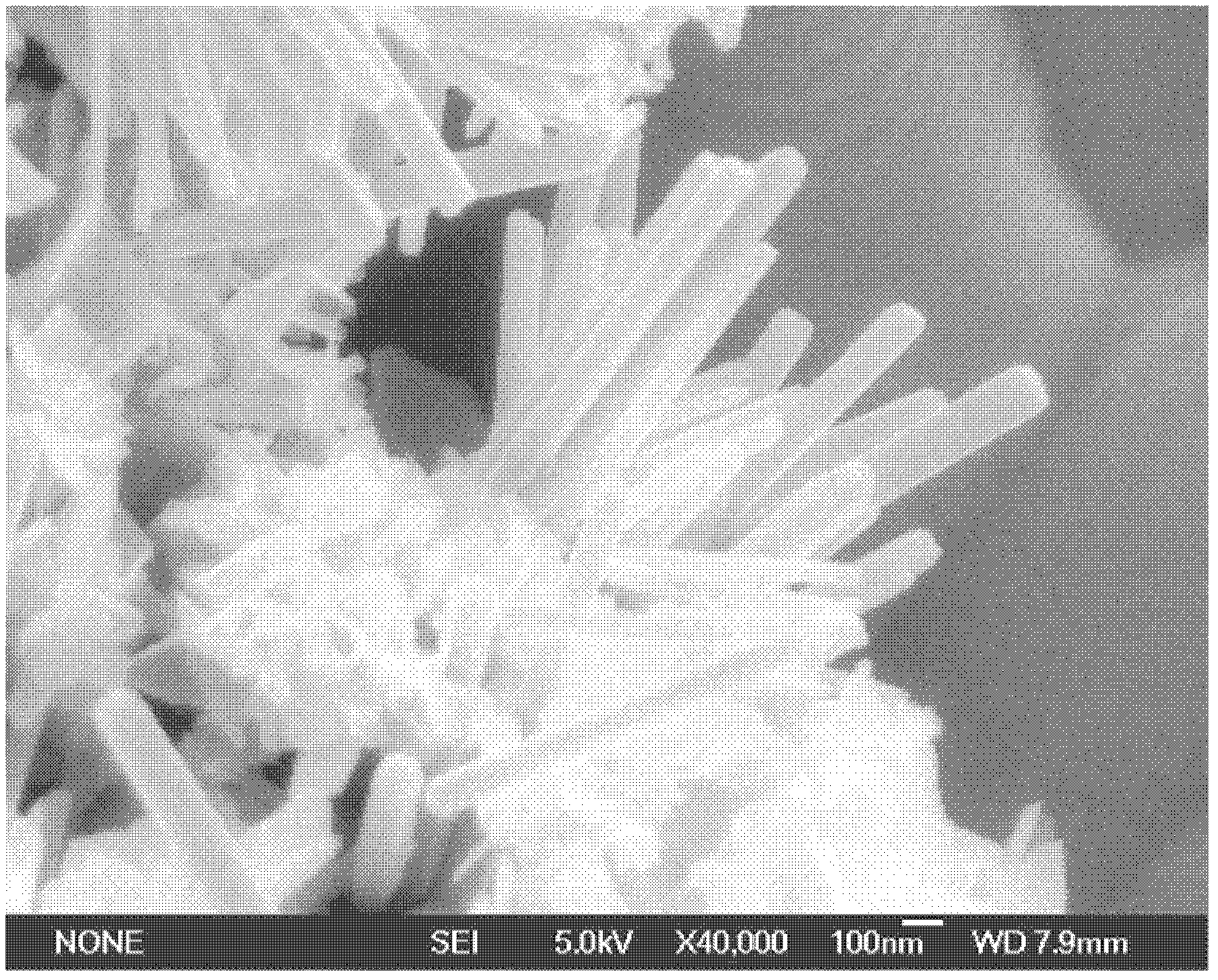

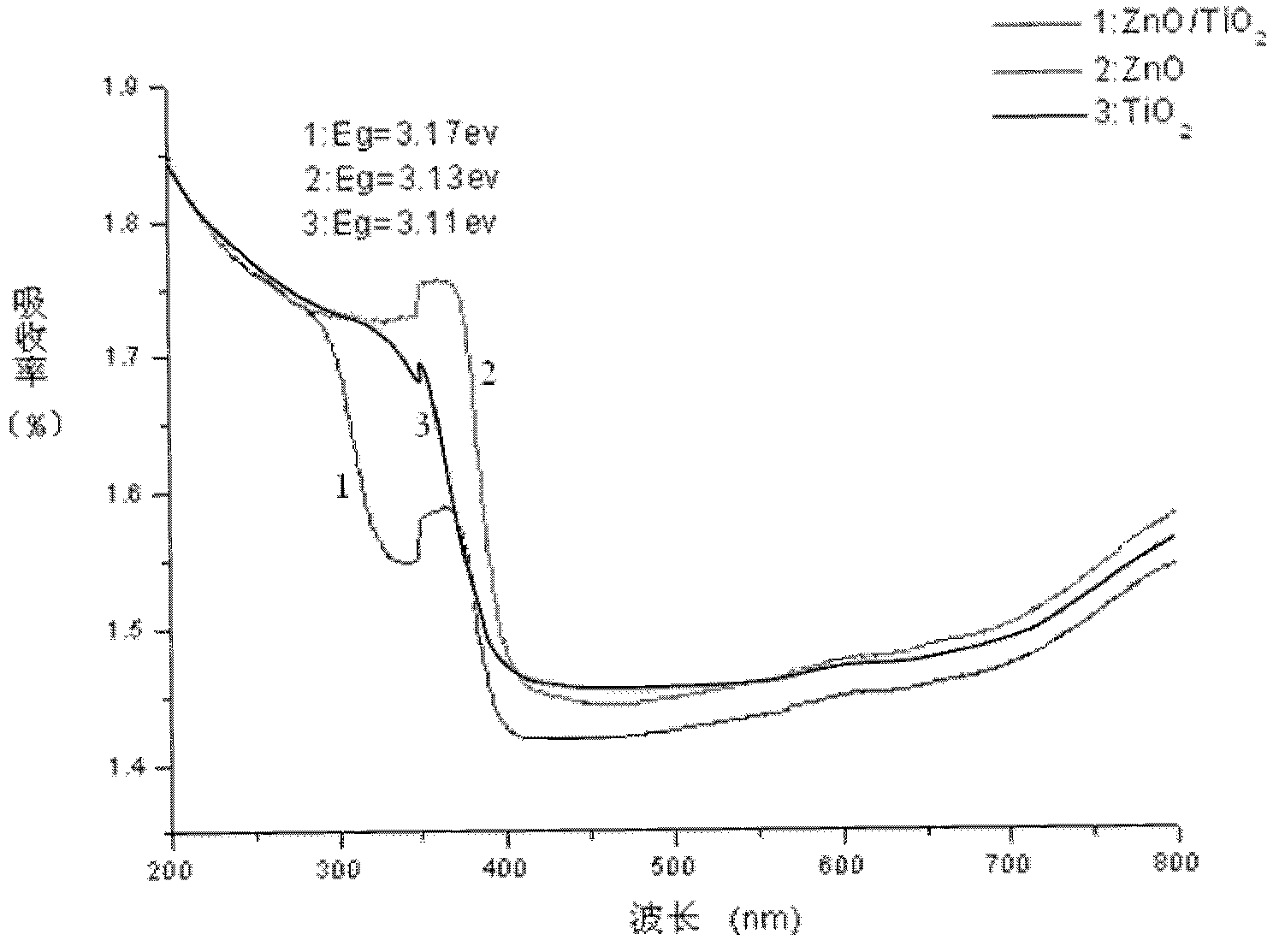

[0054] The prepared ZnO / TiO 2 The composite powder is scanned by an electron microscope to obtain an electron microscope scanning photo, such as figure 1 , figure 2 As shown, the prepared ZnO / TiO 2 The compo...

Embodiment 2

[0057] 1) Dissolve 0.002mol zinc acetate and 0.4g (0.001148mol) sodium dodecylbenzenesulfonate in ethanol, then add 0.004mol tetrabutyl titanate, and mix to obtain 10mL raw material solution;

[0058] 2) under stirring condition, in the raw material liquid in step 1), add dropwise the sodium hydroxide aqueous solution of 10mL, the concentration of sodium hydroxide in the sodium hydroxide aqueous solution is 4mol / L, and the rate of addition of the sodium hydroxide aqueous solution is 0.2 mL / min, the dropping time is 50min;

[0059] 3) The mixture in step 2) was reacted in an autoclave at 160°C for 12h, and after centrifugation, it was washed 3 times with distilled water and then 3 times with ethanol, and dried at 80°C for 12h to obtain 0.425g of ZnO / TiO 2 Composite powder.

[0060] It can be seen from the scanning electron microscope photo that the prepared ZnO / TiO 2 The composite powder is a rod-shaped particle with a diameter of 50nm to 150nm and a length of 1μm to 1.5μm. T...

Embodiment 3

[0062] 1) Dissolve 0.002mol zinc acetate and 0.4g (0.001148mol) sodium dodecylbenzenesulfonate in ethanol, then add 0.004mol tetrabutyl titanate, and mix to obtain 10mL raw material solution;

[0063] 2) under stirring condition, in the raw material liquid in step 1), add dropwise the sodium hydroxide aqueous solution of 10mL, the concentration of sodium hydroxide in the sodium hydroxide aqueous solution is 6mol / L, and the rate of addition of the sodium hydroxide aqueous solution is 1mL / min, the dropping time is 10min;

[0064] 3) The mixture in step 2) was reacted in an autoclave at 160°C for 12h, and after centrifugation, it was washed 3 times with distilled water and then 3 times with ethanol, and dried at 80°C for 12h to obtain 0.43g of ZnO / TiO 2 Composite powder.

[0065] It can be seen from the scanning electron microscope photo that the prepared ZnO / TiO 2 The composite powder is rod-shaped particles with a diameter of 80nm-200nm and a length of 1.2μm-2μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com