Production method and system of deacidification rice bran oil

A production method and technology of a production system, applied in the field of vegetable oil refining, can solve the problems of harmful substances, low product refining rate, large lye consumption, etc., achieve huge economic and social benefits, improve processing efficiency, and simple equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

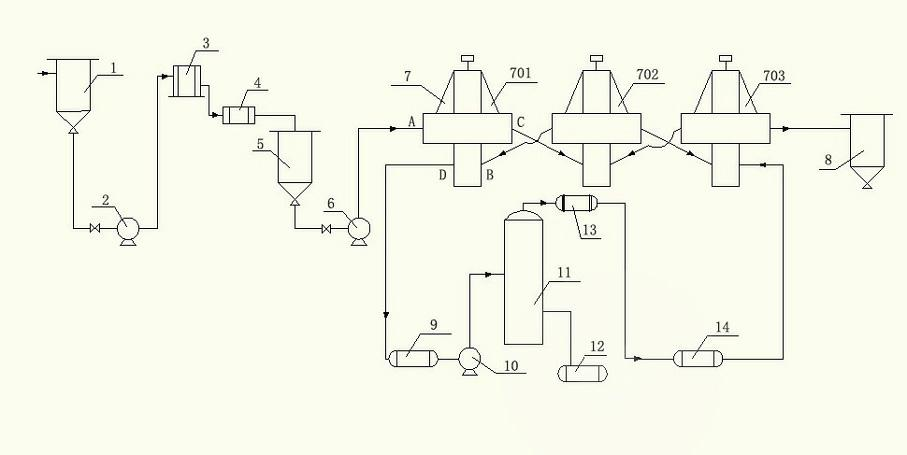

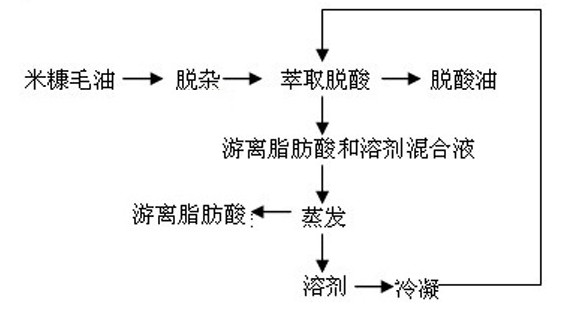

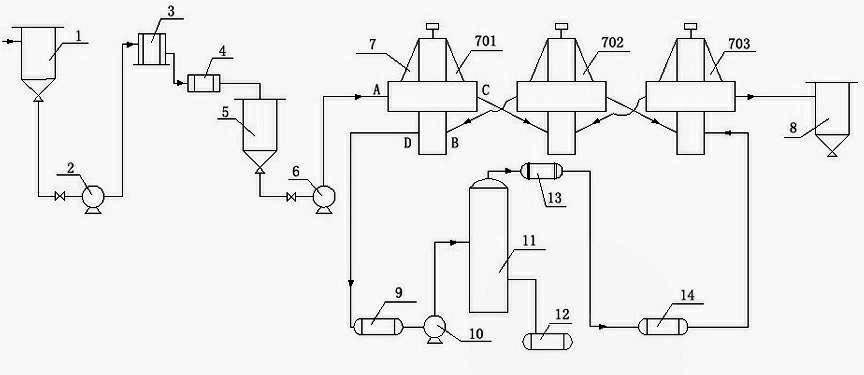

[0030] Such as figure 1 As shown, the rice bran oil deacidification production system includes a crude oil storage tank 1, a heat exchanger 3 connected to the crude oil storage tank 1 through pipelines, and the pipeline between the crude oil storage tank 1 and the heat exchanger 3 is provided with Pump I2, a ball valve is provided on the pipeline between crude oil storage tank 1 and pump I2, plate and frame filter 4 connected to heat exchanger 3, filter oil storage tank 5 connected to plate and frame filter 4, and filter The storage tank 5 is connected to the cylindrical centrifugal extractor 7 through pipelines. The cylindrical centrifugal extractor 7 is formed by connecting at least three monomer extractors in series. Extractor Ⅰ701, cylinder centrifugal extractor Ⅱ702, cylinder centrifugal extractor Ⅲ703, each cylinder centrifugal extractor is equipped with oil inlet A, ethanol inlet B, outlet IC, outlet IID, the former outlet IC and the latter The first-stage oil inlet A ...

Embodiment 2

[0041] The concrete steps of the production method of this rice bran oil deacidification are as follows:

[0042] (1) Rice bran oil filtration

[0043] Put the rice bran oil with a free fatty acid mass content of 25% into the crude oil storage tank 1, send the rice bran oil to the heat exchanger 3 through the pump I2 to raise the temperature of the rice bran oil to 40°C, pass through the plate and frame filter 4 (filter medium The fineness is 100 mesh. At the beginning of filtration, the rice bran oil flows by itself. When the self-flow is not smooth, pressurize and filter. When the pressure in the filter reaches 0.3MPa, carry out slag unloading and cleaning.) After filtering, the impurity content in the rice bran oil is 0.2%, enter the filter oil storage tank 5;

[0044] (2) Extraction and deacidification

[0045] Use the pump II6 to transfer the filtered rice bran oil in the filtered oil storage tank 5 into the cylindrical centrifugal extractor I701 through the first-stage...

Embodiment 3

[0051] The concrete steps of the production method of this rice bran oil deacidification are as follows:

[0052] (1) Rice bran oil filtration

[0053] Put the rice bran oil with a free fatty acid mass content of 30% into the crude oil storage tank 1, send the rice bran oil to the heat exchanger 3 through the pump I2 to raise the temperature of the rice bran oil to 40°C, pass through the plate and frame filter 4 (filter medium The fineness is 90 mesh. At the beginning of filtration, the rice bran oil flows by itself. When the self-flow is not smooth, pressurize and filter. When the pressure in the filter reaches 0.3MPa, carry out slag unloading and cleaning.) After filtering, the impurity content in the rice bran oil is 0.17%, enter the filter oil storage tank 5;

[0054] (2) Extraction and deacidification

[0055] Use the pump II6 to transfer the filtered rice bran oil in the filtered oil storage tank 5 into the cylindrical centrifugal extractor I701 through the first-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com