Liquid injection method of lithium-ion power battery

A power battery and lithium-ion technology, which is applied in the field of lithium-ion power batteries, can solve the problems of unfavorable high-power lithium-ion power batteries, and achieve the effects of improving high-temperature storage performance, prolonging calendar life, and ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

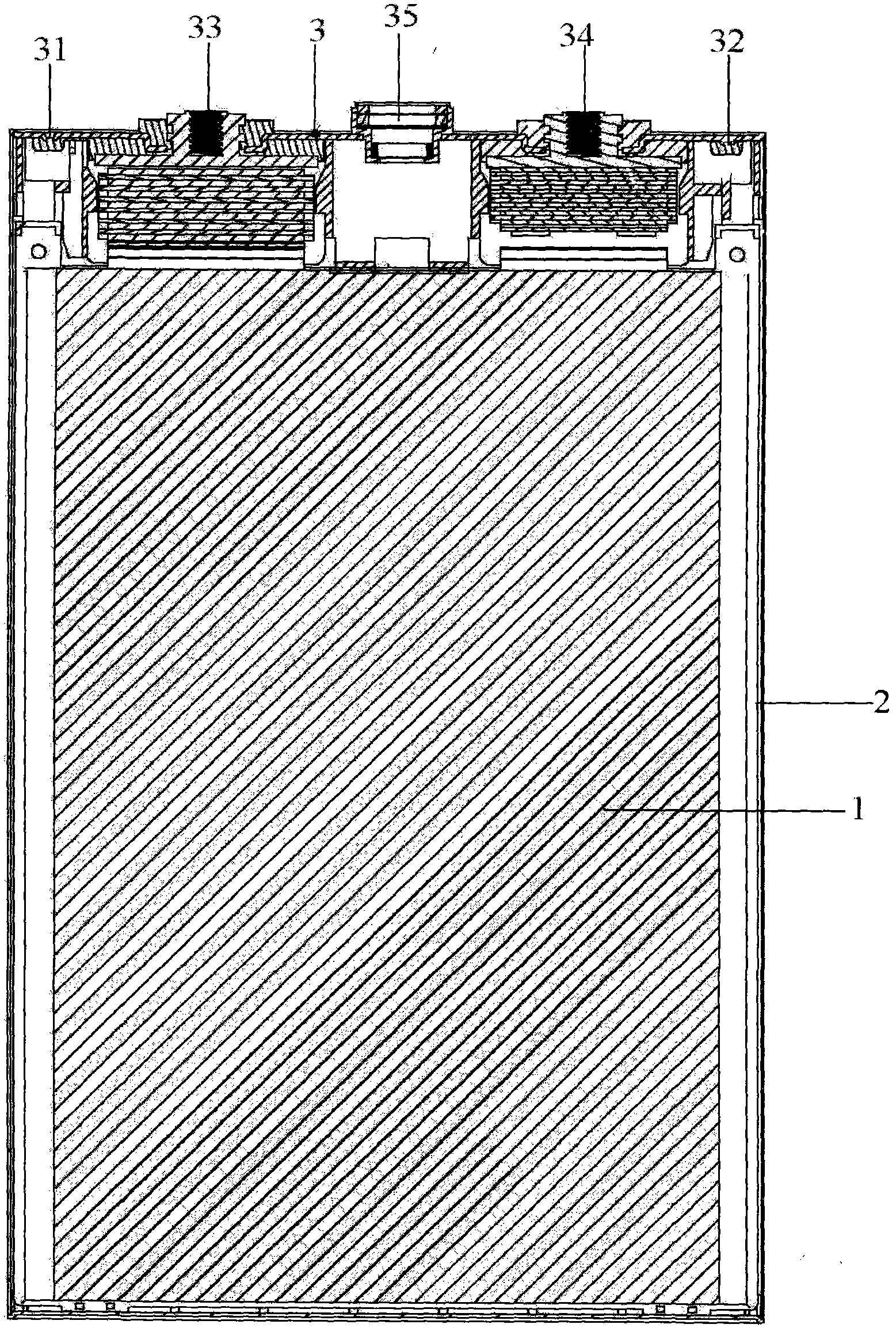

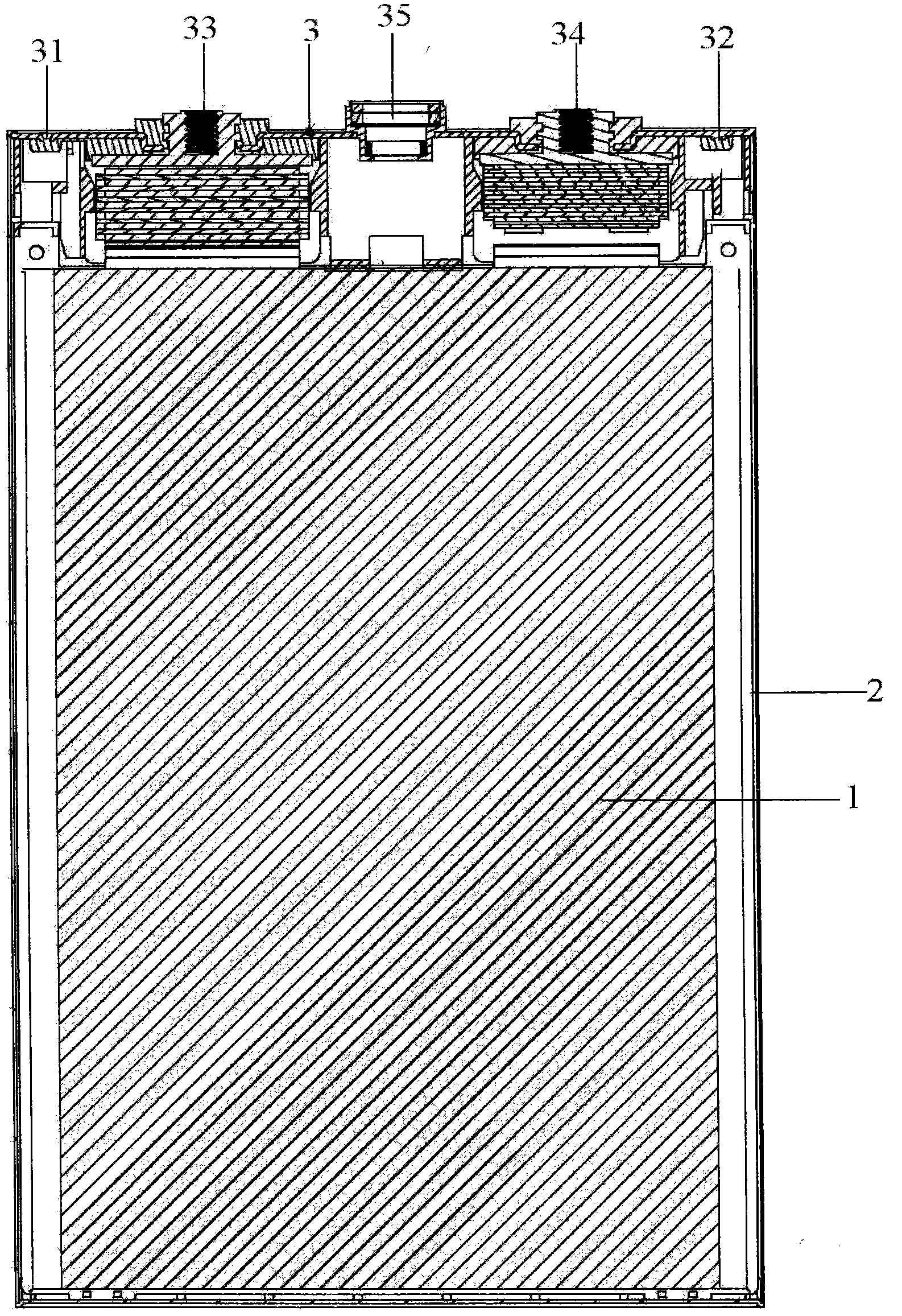

Image

Examples

Embodiment 1

[0030] Preparation of the cathode sheet: the cathode active material LiMn 2 o 4 (Lithium manganese oxide), conductive agent Super-P (conductive carbon) and bonding PVDF (polyvinylidene fluoride) are added to the solvent N-methylpyrrolidone (NMP) according to the mass ratio of 95.0:2.7:2.3 and mixed and stirred evenly to obtain The slurry with a certain fluidity is coated on both sides of the 16um thick metal aluminum foil, and dried into a pole piece with a certain degree of softness.

[0031]Preparation of the anode electrode sheet: artificial graphite is used as the anode active material, carbon powder (Super-P) is used as the conductive agent, styrene-butadiene rubber (SBR) is used as the binder, and sodium carboxymethyl cellulose (CMC) is used as the thickener agent; the above-mentioned anode active material, conductive agent, binder and thickener are added to the solvent deionized water with a mass ratio of 95:2:2:1 and mixed evenly to obtain a fluid anode slurry, and th...

Embodiment 2

[0041] Different from Example 1 is the preparation of electrolyte:

[0042] Preparation of Electrolyte E1:

[0043] Mix ethylene carbonate (EC), propylene carbonate (PC) and dimethyl carbonate (DMC) uniformly in a mass ratio of 3:3:4 to obtain a mixed solvent, and then add lithium tetrafluoroborate (LiBF 4 ), and lithium tetrafluoroborate (LiBF 4 ) concentration is 1.2M, then add high-temperature additive ethylene carbonate (VEC), ethylene carbonate (VEC) accounts for 1% of the total mass of the electrolyte E1.

[0044] Preparation of Electrolyte E2:

[0045] Mix ethylene carbonate (EC), propylene carbonate (PC) and diethyl carbonate (DMC) in a mass ratio of 3:3:4 to obtain a mixed solvent, and then add lithium tetrafluoroborate (LiBF 4 ), and lithium tetrafluoroborate (LiBF 4 ) concentration is 1.2M, then add high-temperature additive ethylene carbonate (VEC), ethylene carbonate (VEC) accounts for 15% of the total mass of the electrolyte E1.

[0046] In addition, the inj...

Embodiment 3

[0050] Different from Example 1 is the preparation of electrolyte:

[0051] Preparation of Electrolyte E1:

[0052] Mix ethylene carbonate (EC), propylene carbonate (PC) and ethyl methyl carbonate (EMC) uniformly in a mass ratio of 3:3:4 to obtain a mixed solvent, then add lithium bisoxalate borate (LiBOB) and make the bis The concentration of lithium oxalate borate (LiBOB) is 0.8M, and then high-temperature additive ethylene carbonate (VEC) is added, and ethylene carbonate (VEC) accounts for 0.5% of the total mass of the electrolyte E1.

[0053] Preparation of Electrolyte E2:

[0054] Mix ethylene carbonate (EC), propylene carbonate (PC) and ethyl methyl carbonate (EMC) uniformly in a mass ratio of 3:3:4 to obtain a mixed solvent, then add lithium bisoxalate borate (LiBOB) and make the bis The concentration of lithium oxalate borate (LiBOB) is 0.8M, and then the high-temperature additive ethylene carbonate (VEC) is added, and ethylene carbonate (VEC) accounts for 25% of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com