Method for preparing magnesium alloy ingot and solidification system

A magnesium alloy and ingot casting technology, which is applied in the field of magnesium alloy ingot preparation, can solve the problems of complex equipment, high cost, and many process parameters, and achieve the effect of simple production equipment, high production efficiency, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

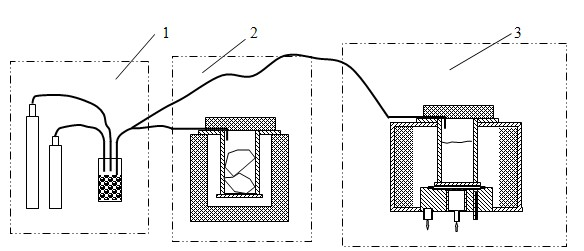

[0036] Such as figure 1 As shown, the equipment used in the preparation method of the magnesium alloy ingot includes a shielding gas configuration system 1, a smelting system and a solidification system 3. The shielding gas configuration system 1 sends the configured shielding gas to the smelting system 2 and the solidification system 3. process and the magnesium alloy melt or high-temperature ingot in the solidification process are protected to prevent oxidation or combustion; the melting system uses a resistance furnace 2 to complete the melting, refining, temperature and composition of the magnesium alloy; the solidification system 3 completes the ingot Control of coagulated tissue.

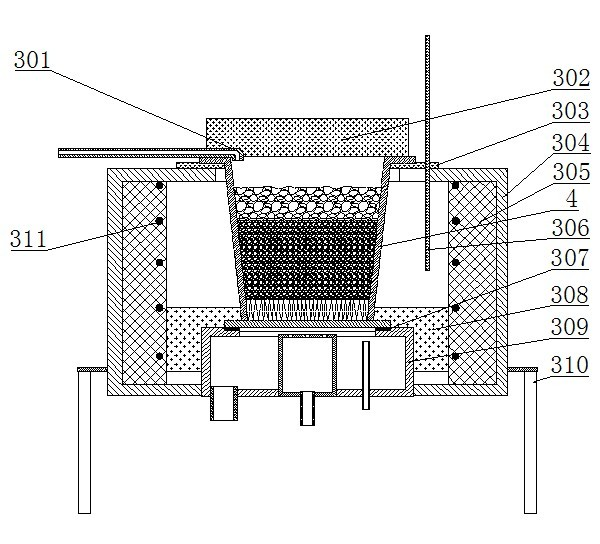

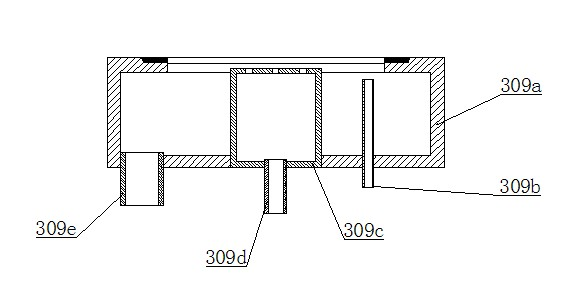

[0037] Such as figure 2 As shown, the solidification system 3 includes a furnace shell 304, a heat preservation furnace body 305, a resistance wire 311 arranged in the heat preservation furnace body, a bracket 310 is provided at the bottom of the furnace shell 305, and a heat preservation ga...

Embodiment 2

[0048] The equipment used is the same as in Example 1.

[0049] The preparation method of magnesium alloy ingot, concrete steps are as follows:

[0050] (1) batching, drying the crucible 4 and the Mg-Al base metal charge before smelting;

[0051] (2) Put the dried charge into the crucible 4, put the crucible 4 into the resistance furnace 2 that has been preheated to 360°C for melting, and when the furnace temperature is 410°C, feed 99.8% CO 2 +0.2%SF 6 The mixed gas protects the melt;

[0052] (3) Use the method of heating up in stages to control the heating rate. The temperature of the furnace is raised by 60°C each time, and then keep warm, and observe the melt temperature value. When the melt temperature value is equal to the furnace temperature, continue to increase the furnace temperature until the melting The body temperature reaches the set value of 890°C;

[0053] (4) When the melt temperature reaches the set temperature, move the crucible 4 with the protective ga...

Embodiment 3

[0058] The equipment used is the same as in Example 1.

[0059] The specific steps of magnesium alloy ingot casting are as follows:

[0060] (1) batching, drying the crucible 4 and the Mg-Al base metal charge before smelting;

[0061] (2) Put the dried charge into the crucible 4, put the crucible 4 into the resistance furnace 2 that has been preheated to 350°C for melting, and when the furnace temperature is 400°C, feed 99.7% CO according to the volume ratio 2 +0.3%SF 6 The mixed gas protects the melt;

[0062] (3) Use the method of heating up in stages to control the heating rate. The temperature of the furnace is raised by 50°C each time, and then keep warm, and observe the temperature of the melt. When the temperature of the melt is equal to the temperature of the furnace, continue to increase the temperature of the furnace until the melting The body temperature reaches the set temperature of 800°C;

[0063] (4) When the melt temperature reaches the set temperature, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com