Shampoo salt emulsion and preparation method thereof

A technology of shampoo salt and edible salt, applied in hair care, pharmaceutical formulations, cosmetic preparations, etc., can solve the problem of large amount of ZPT, and achieve the effect of maintaining moisture, rich foam, and improving sterilization and itching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

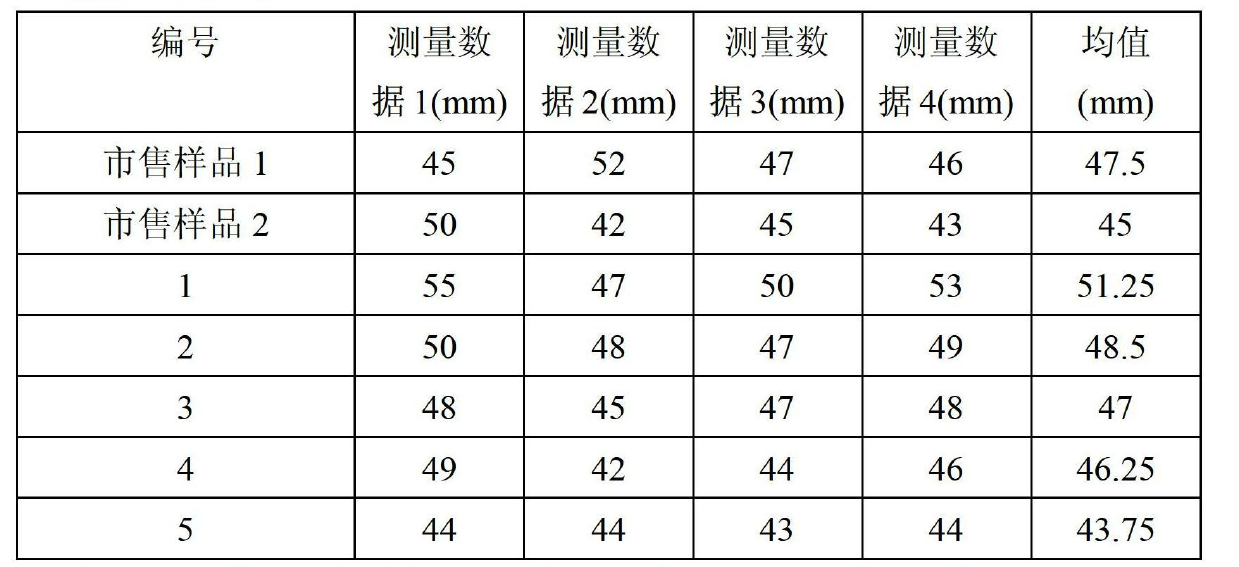

Image

Examples

Embodiment 1

[0038] Embodiment one: the formula basic composition of the present embodiment is:

[0039] 30 parts of sea salt, 13 parts of sodium lauryl ether sulfate (purity: 70%), 6 parts of lauryl amidopropyl hydroxysulfobetaine (purity: 30%), 5 parts of sodium lauryl sulfate (purity: 92%) , Cocoic acid monoethanolamide (purity: 92%) 1.0 parts, diphthalic acid amide (purity: 98%) 0.5 parts, pyrithione zinc suspension (purity: 50%) 0.5 parts, polydimethyl 2 parts of siloxane, 0.6 parts of lemon essential oil, 0.4 parts of propylene glycol, 0.5 parts of guar gum hydroxypropyl trimethyl ammonium chloride, 0.5 parts of xanthan gum, 0.8 parts of D-panthenol, 39.2 parts of water, the above is by weight number of copies.

[0040] The preparation method comprises the following steps:

[0041] 1. Put distilled water in a reaction pot and heat it to 60°C, then add xanthan gum and guar gum hydroxypropyltrimethylammonium chloride dispersed with propylene glycol into distilled water and stir evenl...

Embodiment 2

[0045] Embodiment two: the formula basic composition of the present embodiment is:

[0046] 25 parts of sea salt, 16 parts of sodium lauryl ether sulfate (purity: 70%), 4 parts of lauryl amidopropyl hydroxysulfobetaine (purity: 30%), 2 parts of sodium lauryl sulfate (purity: 92%) , Cocoic acid monoethanolamide (92% purity) 1.5 parts, diphthalic acid amide (98% purity) 1.0 parts, zinc pyrithione suspension (50% purity) 1.0 parts, polydimethyl 3 parts of silicone, 1 part of dimethiconol, 0.3 part of rose essential oil, 1 part of glycerin, 0.5 part of cationic cellulose, 0.4 part of xanthan gum, 0.5 part of cetostearyl alcohol, D-panthenol 0.3 parts, 0.5 parts of vitamin E, 42 parts of water, the above are mass percentages.

[0047] The preparation method comprises the following steps:

[0048] 1. Put the distilled water in the reaction pot and heat it to 60°C, then add the xanthan gum and cationic cellulose dispersed with glycerin into the distilled water and stir evenly;

[...

Embodiment 3

[0052] Embodiment three: the formula of this embodiment basically consists of:

[0053] 20 parts of sea salt, 17 parts of ammonium laureth sulfate (purity: 70%), 4 parts of lauryl amidopropyl hydroxysulfobetaine (purity: 30%), 4 parts of ammonium lauryl sulfate (purity: 70%), Cocoic acid monoethanolamide (purity 92%) 2 parts, diphthalic acid amide (purity 98%) 1 part, pyrithione zinc suspension (purity 50%) 1 part, polydimethylsiloxane 5 parts of oxane, 0.3 parts of rose essential oil, 1.0 parts of glycerin, 0.3 parts of cationic cellulose, 0.3 parts of guar gum hydroxypropyl trimethyl ammonium chloride, 0.4 parts of xanthan gum, 0.5 parts of hydroxyethyl cellulose, D - 0.3 parts of panthenol, 0.5 parts of silk protein, and 42.4 parts of water, the above are mass percentages.

[0054] The preparation method comprises the following steps:

[0055] 1. Put distilled water in a reaction pot and heat it to 60°C, then add xanthan gum, hydroxyethyl cellulose, cationic cellulose, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com