Method for preparing visible light responding spherical titanium dioxide composite photocatalyst with ferric oxide supported on surface

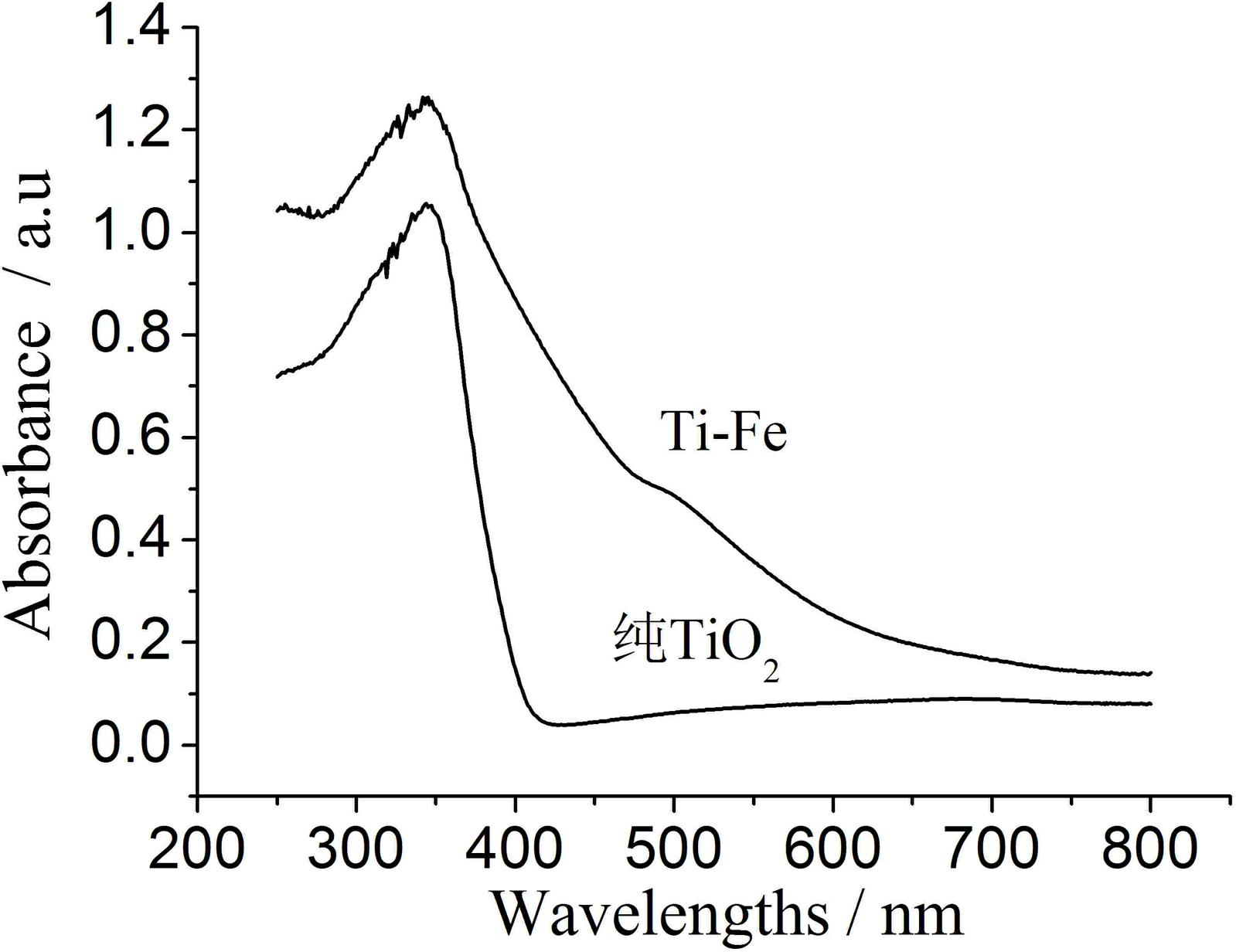

A titanium dioxide, surface-loaded technology, applied in the field of photocatalyst preparation, can solve the problems of affecting the photocatalytic efficiency of semiconductors, the photocatalytic efficiency is not very high, and the solar energy utilization rate is low, achieving low cost, high preparation efficiency and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

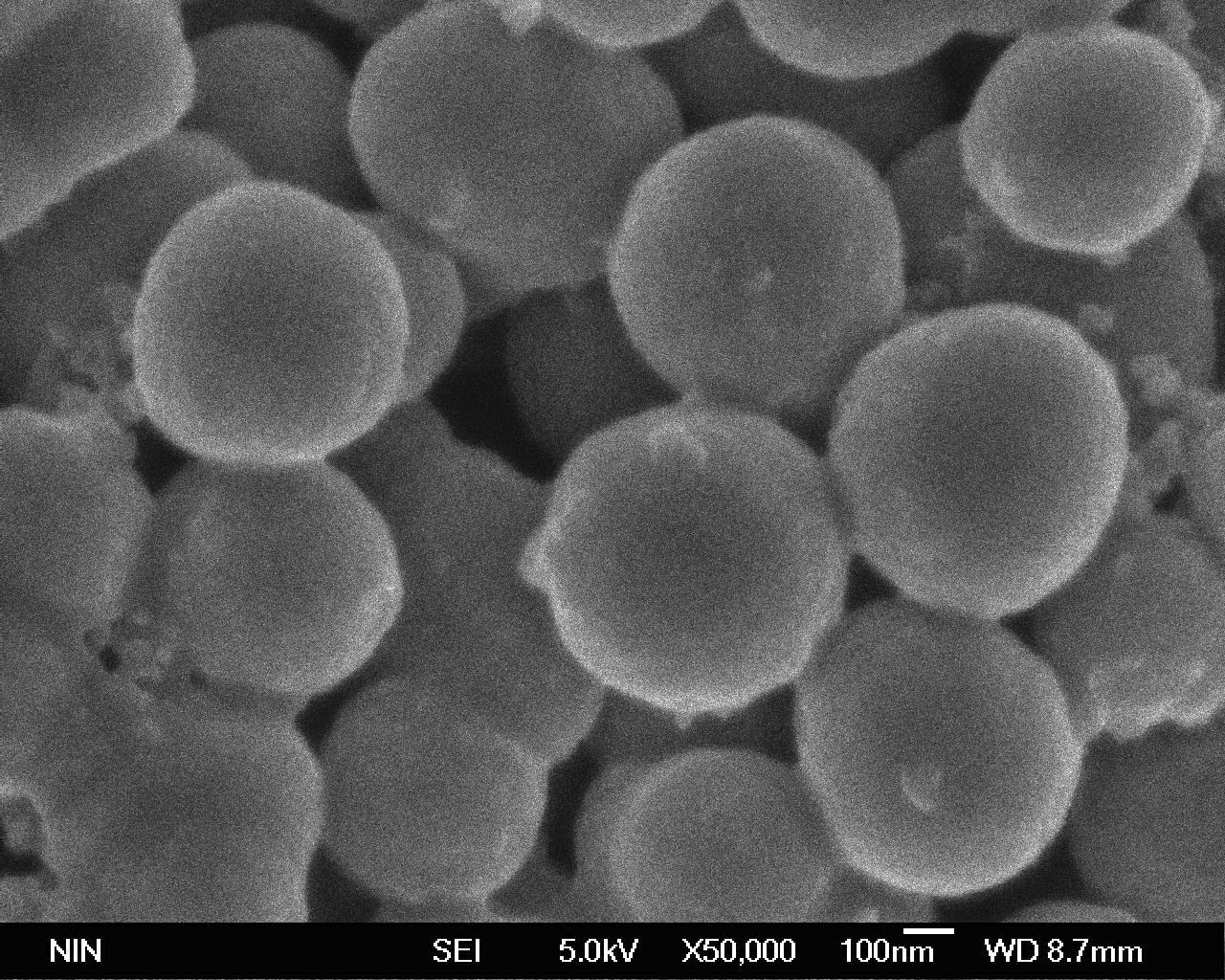

[0020] Step 1: Prepare a lithium chloride solution with a molar concentration of 0.1M; mix the three according to the volume ratio of salt solution: tetrabutyl titanate: absolute ethanol = 0.3: 1.5: 100, and stir vigorously until a titanium dioxide sol is formed; After standing for 24 hours, centrifuge and wash with absolute ethanol, and dry at 80°C for 12 hours under vacuum to obtain spherical titanium dioxide particles;

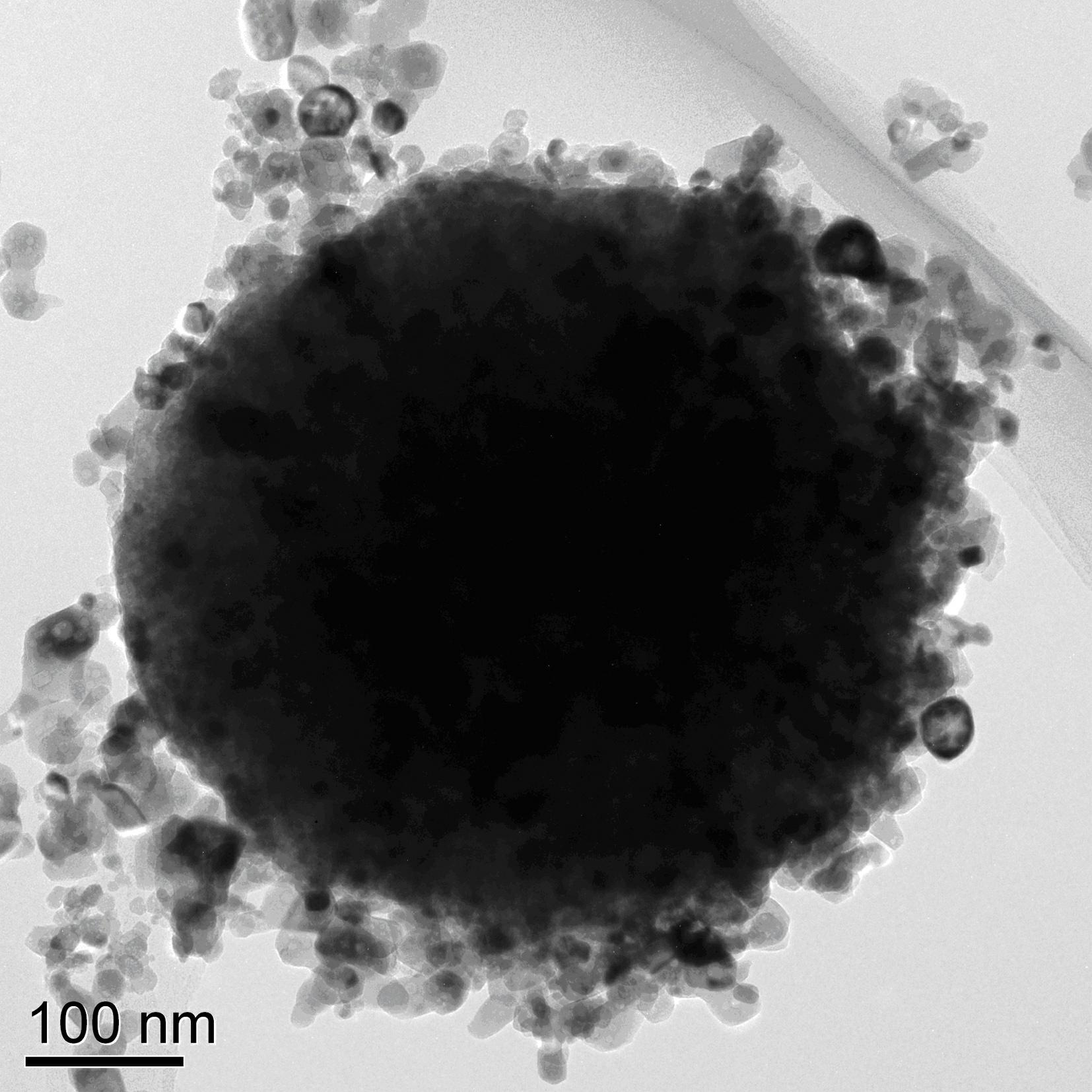

[0021] Step 2: Prepare a ferric chloride solution with a molar concentration of 0.01M; disperse the titanium dioxide microspheres prepared in step 1 into the iron salt solution at a ratio of 0.001:1 by mass ratio of iron element to titanium dioxide; or according to the mass ratio of iron: Titanium dioxide: deionized water = 0.001:1:20, first dissolve the iron salt solid powder with deionized water, then add the titanium dioxide powder prepared in step 1; magnetically stir for 15 minutes and then ultrasonically disperse for 15 minutes, so that the titanium di...

Embodiment 2

[0023] Step 1: Prepare a sodium chloride solution with a molar concentration of 0.1M; mix the three according to the volume ratio of salt solution: tetrabutyl titanate: absolute ethanol = 0.4:2:100, and stir vigorously until a titanium dioxide sol is formed; After standing for 24 hours, centrifuge and wash with absolute ethanol, and dry at 80°C for 12 hours under vacuum to obtain spherical titanium dioxide particles;

[0024] Step 2: Prepare a ferric nitrate solution with a molar concentration of 0.05M; disperse the titanium dioxide microspheres prepared in step 1 into the iron salt solution at a ratio of 0.01:1 by mass ratio of iron element to titanium dioxide; or according to the mass ratio iron:titanium dioxide : Deionized water = 0.01:1:20, firstly dissolve the iron salt solid powder with deionized water, then add the titanium dioxide powder prepared in step 1; magnetically stir for 15 minutes and then ultrasonically disperse for 15 minutes to completely disperse the titani...

Embodiment 3

[0026] Step 1: Prepare a sodium chloride solution with a molar concentration of 0.1M; mix the three according to the volume ratio of salt solution: tetrabutyl titanate: absolute ethanol = 0.5:2:100, and stir vigorously until a titanium dioxide sol is formed; After standing for 24 hours, centrifuge and wash with absolute ethanol, and dry at 80°C for 12 hours under vacuum to obtain spherical titanium dioxide particles;

[0027] Step 2: Prepare a ferric sulfate solution with a molar concentration of 0.05M; disperse the titanium dioxide microspheres prepared in step 1 into the iron salt solution at a ratio of 0.01:1 by mass ratio of iron element to titanium dioxide; or according to the mass ratio iron:titanium dioxide : Deionized water = 0.01:1:20, firstly dissolve the iron salt solid powder with deionized water, then add the titanium dioxide powder prepared in step 1; magnetically stir for 15 minutes and then ultrasonically disperse for 15 minutes to completely disperse the titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com